Thermosensitive Filler Composition

The technology of filler and composition is applied in the field of temperature-sensitive filler composition for injection, which can solve the problems of affecting the treatment effect, destroying the stability and treatment effect of polylactic acid microspheres, and achieving the effect of prolonging the shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

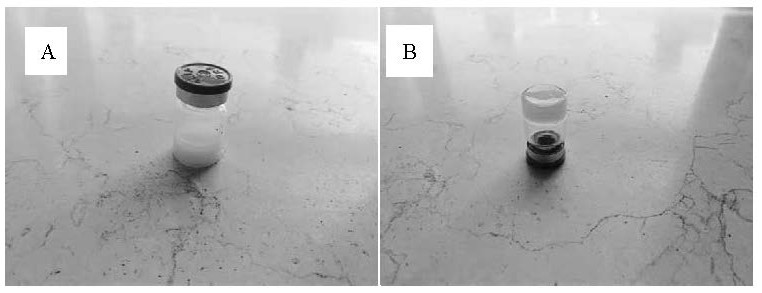

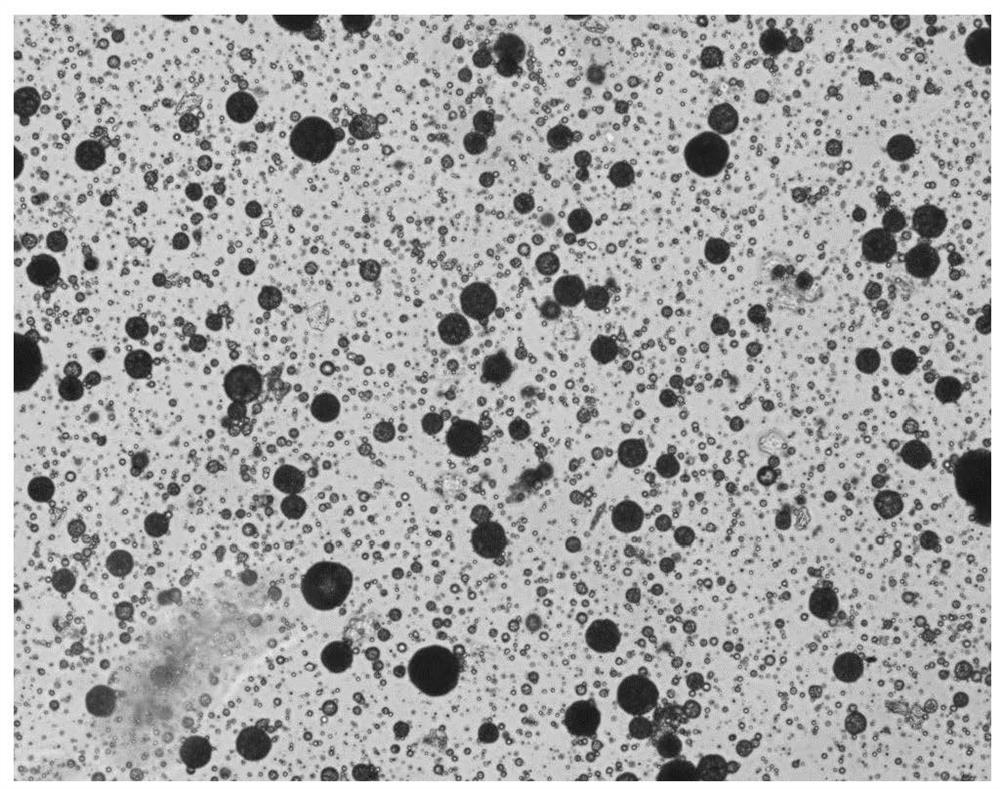

[0037] Add 2 g of L-polylactic acid (PLLA) with a molecular weight of 500,00 to 16 mL of dichloromethane to dissolve, and then add dropwise to 400 mL of 1% polyvinyl alcohol (viscosity of 22.6 mPa.s) aqueous solution. , stirred at room temperature for 1 hour, heated to 45°C, removed dichloromethane to obtain a reaction solution, filtered the reaction solution to collect the filter cake, sieved out microspheres with an average particle size of 20-80 μm, and vacuum-dried to obtain 1.3 g of 20-80 μm polylactic acid Microspheres, which are subpackaged into 60 mg microsphere sample 1 for each bottle for later use. For its optical micrograph, see figure 2 .

[0038] Put 2g of methylcellulose (SM 400) and 0.5g of sodium alginate in a 200ml beaker, add 60mL of 90°C hot water, stir to dissolve, and store in a 4°C refrigerator for later use; add 20mL (0.4g / ml) polyethylene glycol and 14mL (0.25g / ml) of sodium citrate, adjust the pH to 7.4, set the volume to 100mL, stir at 4°C for 12...

Embodiment 2

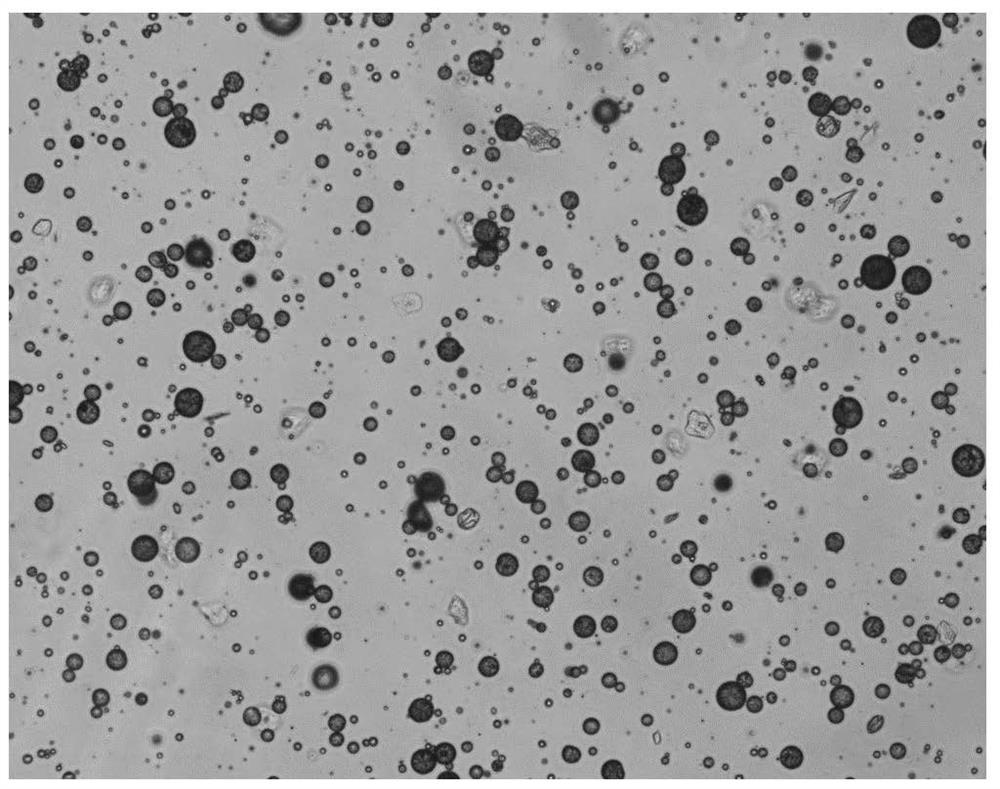

[0041] Add 2 g of racemic polylactic acid (PDLLA) with a molecular weight of 15,000 to 4 mL of dichloromethane to dissolve, then add dropwise to 200 mL of 1% polyvinyl alcohol (viscosity of 22.6 mPa.s) aqueous solution, and the dropwise addition is complete , stir at room temperature for 1 hour, heat up to 45°C, remove dichloromethane to obtain a reaction solution, filter the reaction solution to collect the filter cake, sieve out microspheres with an average particle size of 20-80 μm, and vacuum-dry to obtain 1.4 g of 20-80 μm polylactic acid The microspheres are used as microsphere sample 2 for later use; or they are subpackaged into 60 mg microsphere sample 2 for each bottle for later use. For its optical micrograph, see image 3 .

[0042]Put 20g of Soluplus in a 100ml beaker, add 80mL of 0.05M PBS with pH7.4, stir to dissolve, and constant volume to obtain 100mL of gel. Heat and sterilize the temperature-sensitive gel to obtain temperature-sensitive gel sample 2, and sto...

Embodiment 3

[0046] Add 2 g of polycaprolactone (PCL) with a molecular weight of 50,000 to 12 mL of dichloromethane to dissolve, then add dropwise to 200 mL of a 1% polyvinyl alcohol (viscosity of 22.6 mPa.s) aqueous solution, and the dropwise addition is complete , stirred at room temperature for 1 hour, heated up to 45°C, removed dichloromethane to obtain a reaction solution, filtered the reaction solution to collect the filter cake, sieved out microspheres with an average particle size of 20-80 μm, and vacuum-dried to obtain 1.5 g of 20-80 μm polyhexene The lactone microspheres are used as the microsphere sample 3 for later use; or it is subpackaged into each bottle of 60 mg microsphere sample 3 for later use. For its optical micrograph, see Figure 4 .

[0047] Place 18g of poloxamer 407, 2g of poloxamer 188, 0.5g of sodium carboxymethylcellulose (viscosity of 12000mPa.s) and 0.25g of polyethylene oxide (PEO) with an average molecular weight of 5 million in a 100ml beaker , add 80mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com