VCI degradable antirust film

A biodegradant and raw material technology, applied in the direction of climate sustainability, sustainable packaging industry, sustainable manufacturing/processing, etc., can solve the problems of weight loss, strength reduction, fragmentation, etc., and achieve ideal degradation effect, preparation method Simple, easily degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1V

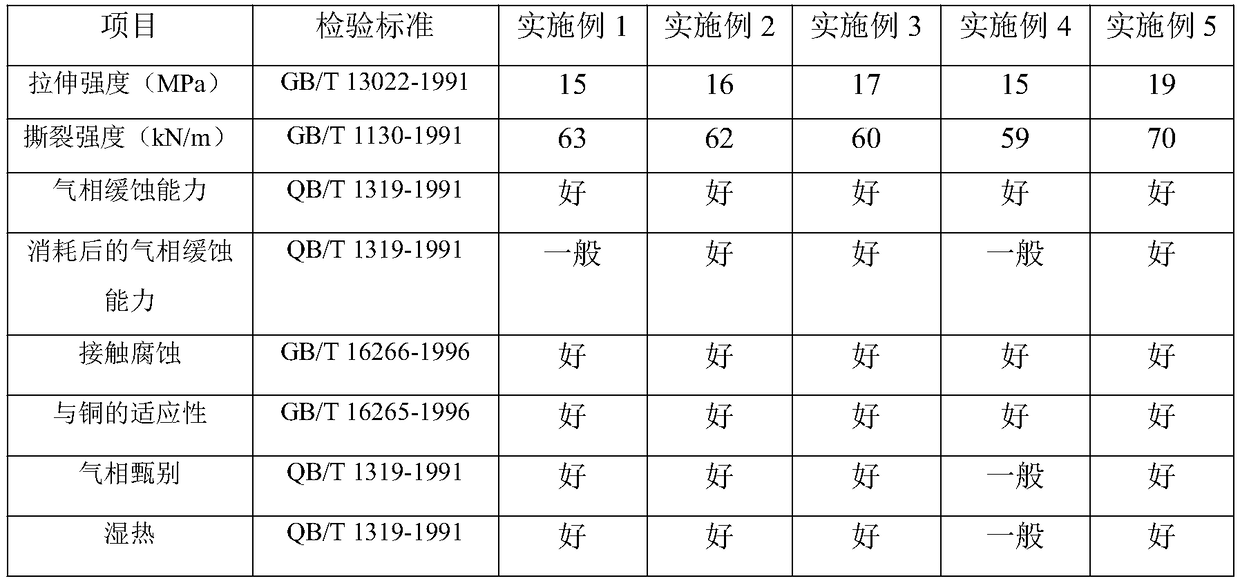

[0022] The preparation of embodiment 1VCI degradable anti-rust film

[0023] Raw material composition:

[0024] The outer layer is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl alcohol, 50 parts of cellulose, 20 parts of photosensitizer and 20 parts of biodegradation agent;

[0025] The inner layer is a gas-phase corrosion inhibitor mixed layer, which is prepared from the following raw materials in parts by weight: 100 parts of PP resin, 10 parts of ammonium chromate, 15 parts of monoethanolamine benzoate, 20 parts of o-nitrophenol dicyclohexylamine, cyclohexyl 10 parts of amine, 30 parts of calcium carbonate, 10 parts of talcum powder, 15 parts of diisononyl phthalate, 5 parts of sodium benzoate, 2 parts of dextrin, 3 parts of benzotriazole, 3 parts of sodium molybdate, hydroxy 3 parts of ethyl cellulose, 4 parts of zinc stearate and 4 parts of polyethylene wax.

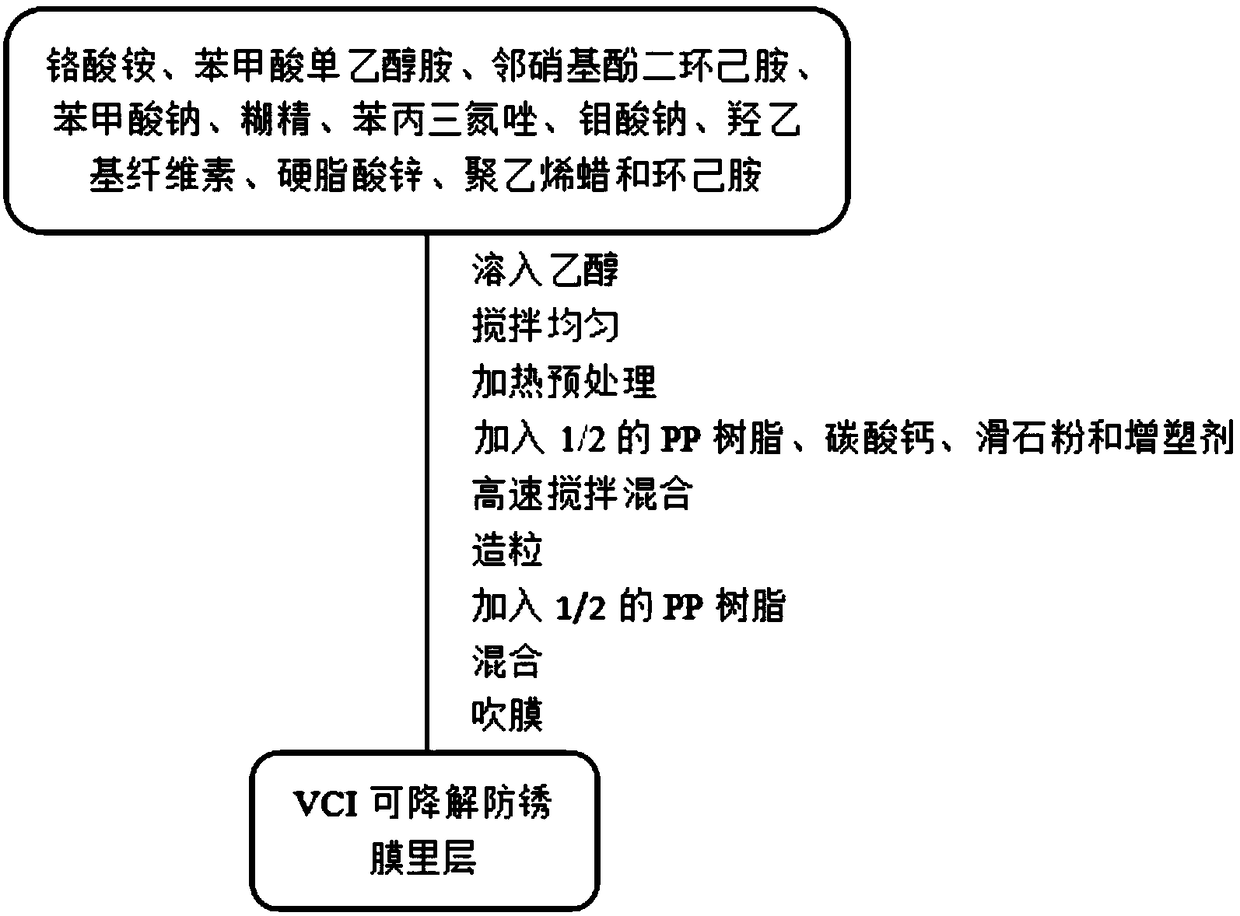

[0026] The inner layer is prepared by the following method: ammonium chr...

Embodiment 2V

[0028] The preparation of embodiment 2VCI degradable anti-rust film

[0029] Raw material composition:

[0030] The outer layer is prepared from the following raw materials in parts by weight: 150 parts of polyvinyl alcohol, 90 parts of carboxymethyl cellulose, 40 parts of photosensitizer and 50 parts of biodegradation agent;

[0031] The inner layer is a gas-phase corrosion inhibitor mixed layer, which is prepared from the following raw materials in parts by weight: 120 parts of PP resin, 30 parts of ammonium chromate, 25 parts of monoethanolamine benzoate, 40 parts of o-nitrophenol dicyclohexylamine, cyclohexyl 20 parts of amine, 50 parts of calcium carbonate, 20 parts of talcum powder, 25 parts of bis(2-ethylhexyl) phthalate, 15 parts of sodium benzoate, 6 parts of dextrin, 9 parts of benzotriazole, molybdic acid Sodium 9 parts, hydroxyethyl cellulose 8 parts, zinc stearate 10 parts and polyethylene wax 10 parts.

[0032]The inner layer is prepared by the following method...

Embodiment 3V

[0034] The preparation of embodiment 3VCI degradable anti-rust film

[0035] Raw material composition:

[0036] The outer layer is prepared from the following raw materials in parts by weight: 120 parts of polyvinyl alcohol, 60 parts of starch, 25 parts of photosensitizer and 30 parts of biodegradation agent;

[0037] The inner layer is prepared from the following raw materials in parts by weight: 105 parts of PP resin, 15 parts of ammonium chromate, 17 parts of monoethanolamine benzoate, 25 parts of o-nitrophenol dicyclohexylamine, 12 parts of cyclohexylamine, and 35 parts of calcium carbonate , 12 parts of talcum powder, 17 parts of diisodecyl phthalate, 7 parts of sodium benzoate, 3 parts of dextrin, 5 parts of benzotriazole, 5 parts of sodium molybdate, 4 parts of hydroxyethyl cellulose, hard 6 parts of zinc fatty acid and 6 parts of polyethylene wax.

[0038] The inner layer is prepared by the following method: ammonium chromate, monoethanolamine benzoate, o-nitrophenol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com