Glass kiln flue gas desulfurization agent and preparation method of sulfur removal agent

A glass kiln and flue gas technology, applied in the field of flue gas desulfurization, can solve the problem of incomplete absorption of sulfur-containing substances, and achieve the effects of low surface tension, reduced pollution, and reduced sulfur-containing substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

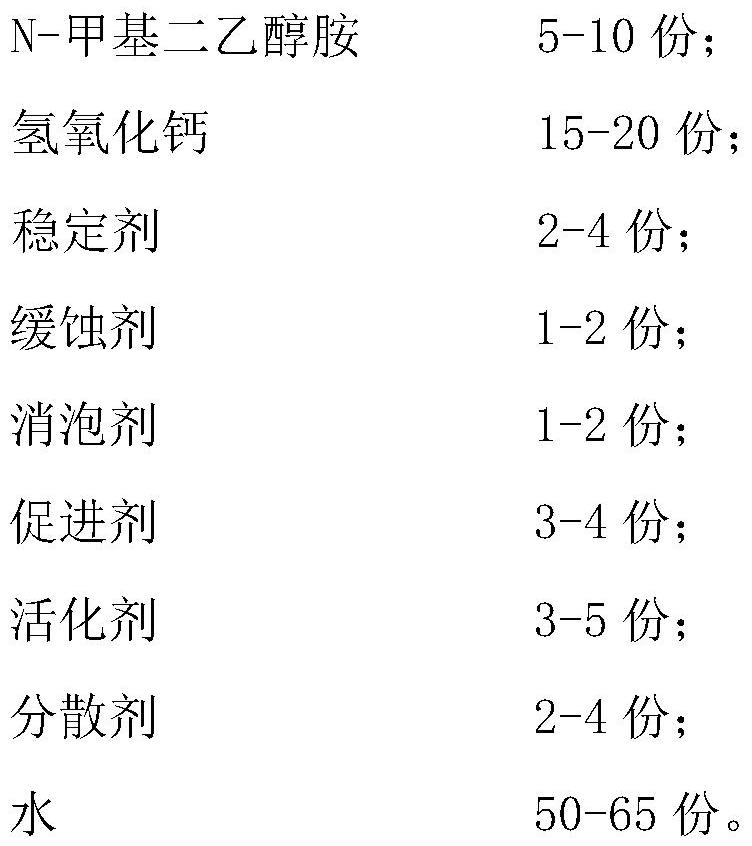

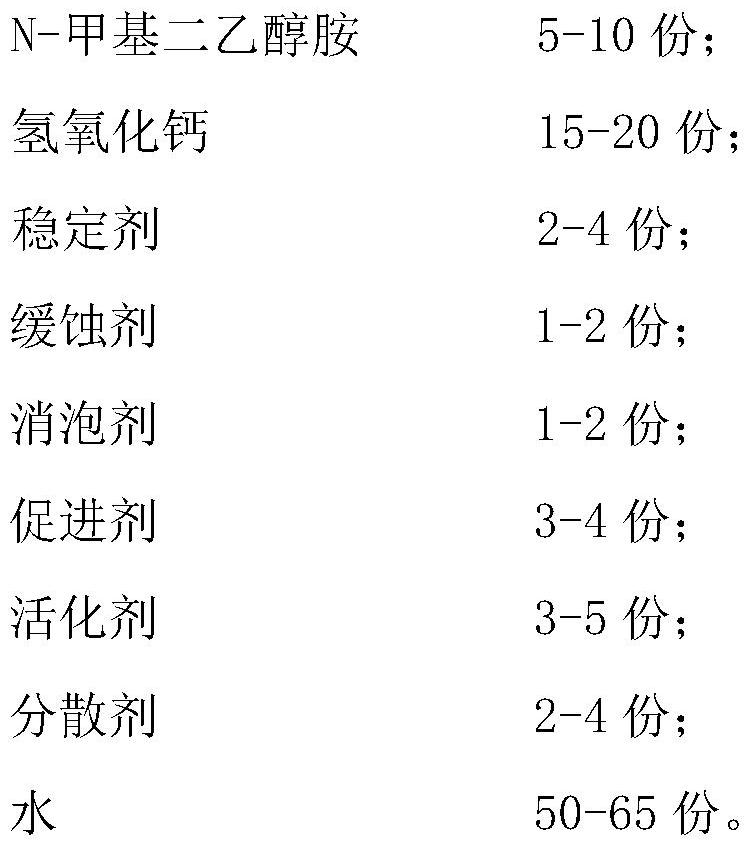

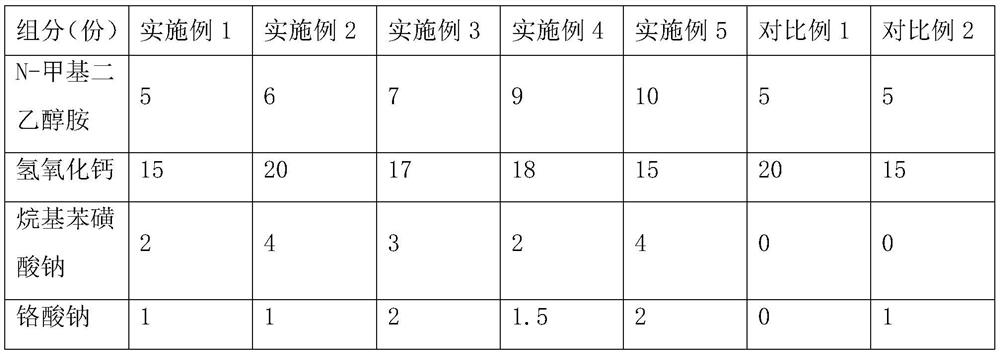

[0026] Embodiment 1, a kind of sulfur removal agent of glass kiln flue gas, N-methyldiethanolamine, calcium hydroxide, stabilizer, corrosion inhibitor, defoamer, accelerator, activator, dispersant and water, wherein remove The weight of each raw material of the sulfur agent is shown in Table 1 in terms of parts by weight per 100 parts by weight of raw materials.

Embodiment 2

[0027] Example 2, a desulfurizer for glass kiln flue gas, differs from Example 1 in that the components and weights in the raw materials are shown in Table 1.

Embodiment 3

[0028] Example 3, a desulfurizer for glass kiln flue gas, differs from Example 1 in that the components and weights in the raw materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com