Preparation method of powdery antimony pentoxide applied to optical glass

A technology of antimony pentoxide and optical glass, which is applied in the fields of chemical instruments and methods, antimony oxide/antimony hydroxide/antimony oxyacid, inorganic chemistry, etc. It can solve the problems of unstable performance of optical glass and decreased yield, etc. To achieve the effect of mild and controllable process, simple raw materials and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

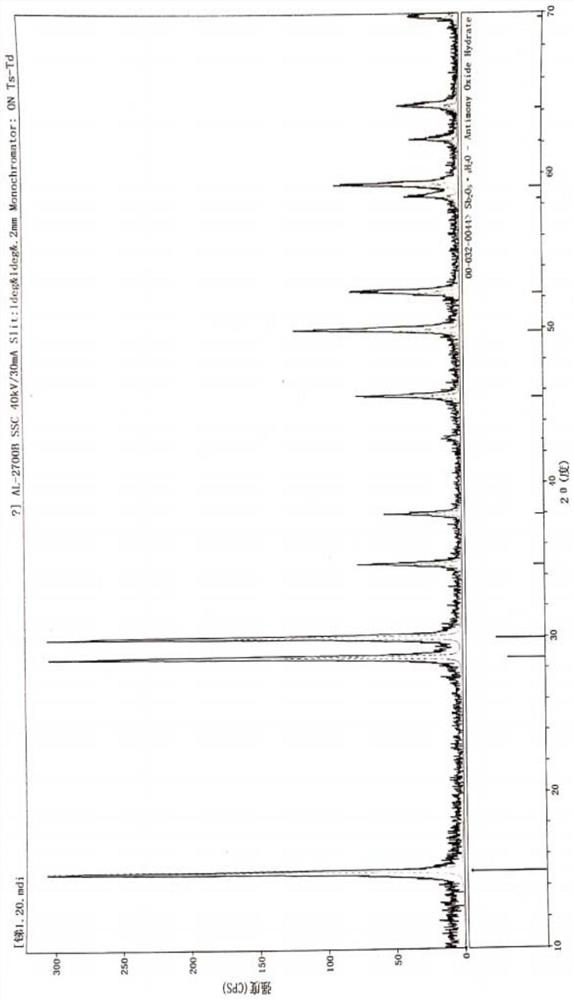

Image

Examples

Embodiment 1

[0047] The present embodiment prepares powder-shaped high purity pentoxide bismuth by the following steps:

[0048] Step 1, prepare four-water-saving bold crude;

[0049] Step 1.1, adding a mass concentration of 40% -42% to the polytetrafluorosphere, heating to 70 ° C, in the stirring state, batch is added in batches, each addition is x, where x = m / 4, M is the total mass of metal antimony powder, the total mass of the metal ruthenium powder and the mass concentration of 40% of the total mass ratio 1: 2.5;

[0050] Step 1.2, in the reaction mixture of step 1.1, a hydrochloride having a mass concentration of 36% is added; after the metal is fully dissolved, the color of the reaction liquid becomes brown, add a certain amount of deionized water, adjust the reaction. Liquid specific weight to 1.20;

[0051] Step 1.3, warmed to 85 ° C, thermal insulation for 5 hours, agonized; heat filtrate, collect the filtrate, remove unreacted metal antimony powder, then the filtrate is mainly te...

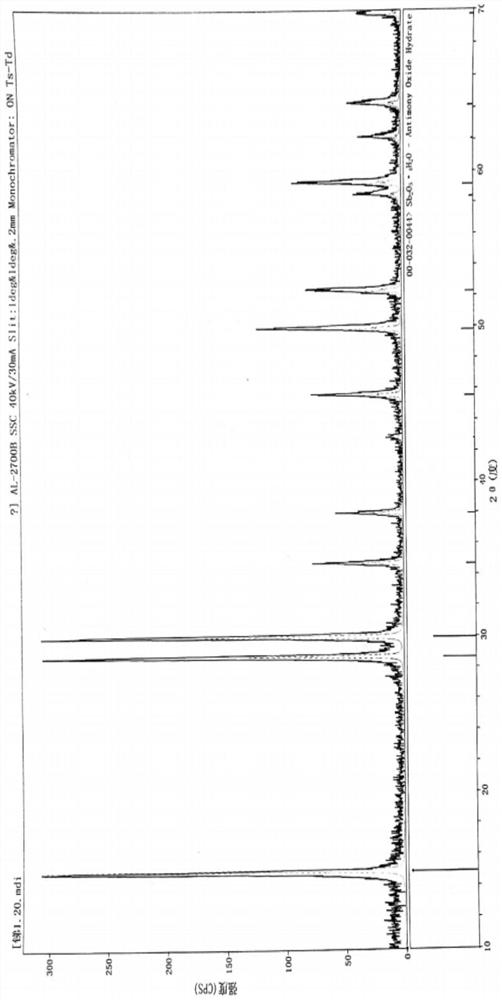

Embodiment 2

[0067] The present embodiment is achieved by the following steps, and the difference between the reaction temperature, time and material ratio of each step is different from that of the first embodiment:

[0068] Step 1, prepare four-water-saving bold crude;

[0069] Step 1.1, adding a mass concentration of 40% -42% to the polytetrafluorosphere, heating to 60 ° C, in the stirring state, a metal powder is added in batches, each addition is x, where x = m / 5, M is the total mass of metal antimony powder, the total mass of metal and high quality and mass concentration of 40% is 1: 3;

[0070] Step 1.2, adding the catalytic amount of 37% hydrochloric acid to the reaction mixture of step 1.1; after the metal is fully dissolved, the color of the reaction liquid becomes brown, add a quantity of deionized water, adjust the reaction. Liquid specific gravity to 1.25;

[0071] Step 1.3, warmed to 80 ° C, thermal insulation for 3 hours, agonize; heat filtrate, collect the filtrate, remove th...

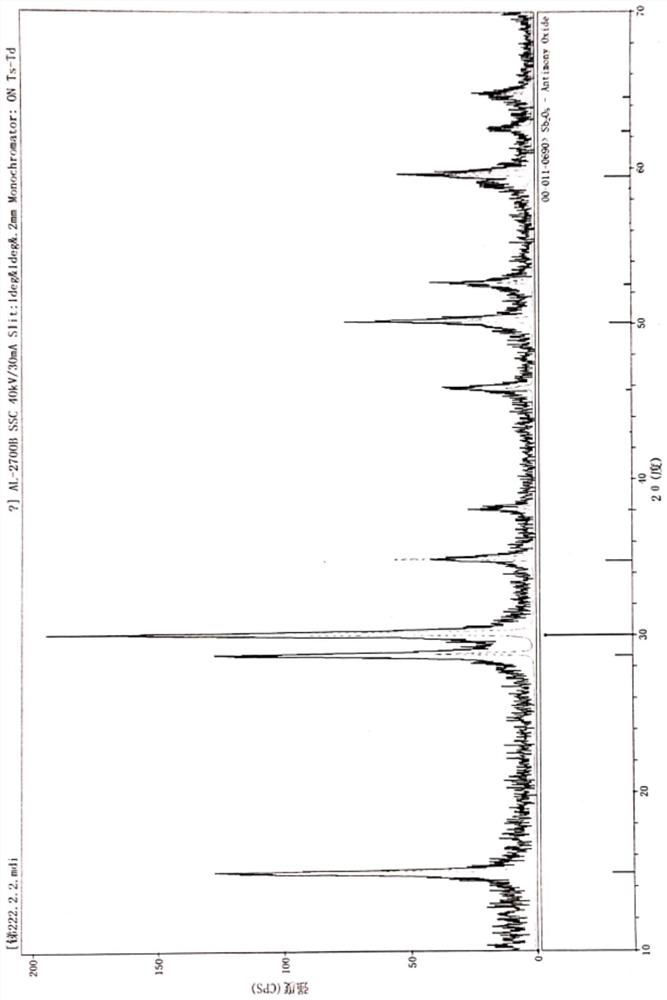

Embodiment 3

[0089] The present embodiment is achieved by the following steps, and the reaction temperature and time of each step is different from that of the first embodiment:

[0090] Step 1, prepare four-water-saving bold crude;

[0091] Step 1.1, adding the nitric acid having a mass concentration of 40% -42% to the polytetrafluorosphere, warmed to 65 ° C, in the agitation state, batch of metal antimony powder, each added to x, where x = m / 4, M is the total mass of metal antimony powder, the total mass of the metal ruthenium powder and the mass concentration of 40% of the total mass ratio 1: 2.5;

[0092] Step 1.2, in the reaction mixture of step 1.1, a hydrochloride having a mass concentration of 36% is added; after the metal is fully dissolved, the color of the reaction liquid becomes brown, add a certain amount of deionized water, adjust the reaction. Liquid specific weight to 1.20;

[0093] Step 1.3, warmed to 85 ° C, thermal insulation for 5 hours, agonized; heat filtrate, collect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com