Preparation method of battery-grade nickel sulfate solution

A nickel sulfate, battery-grade technology, applied in the field of material chemistry, can solve the problems of high process cost, long process, large acid-base consumption, etc., and achieve the effect of shortening process process, facilitating operation and reducing process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

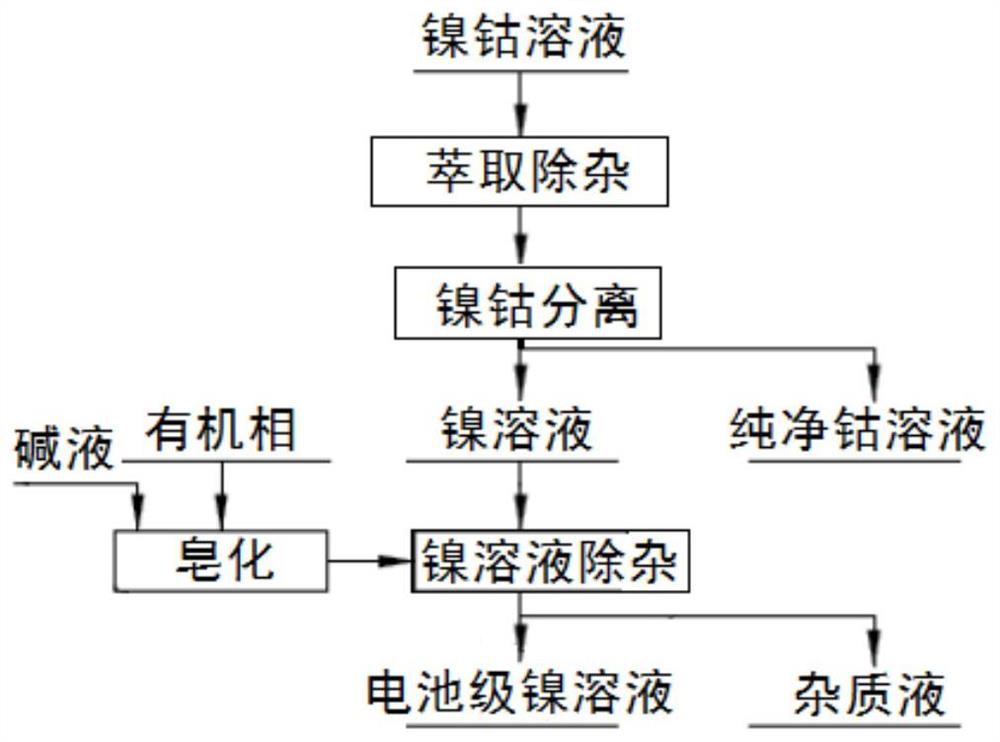

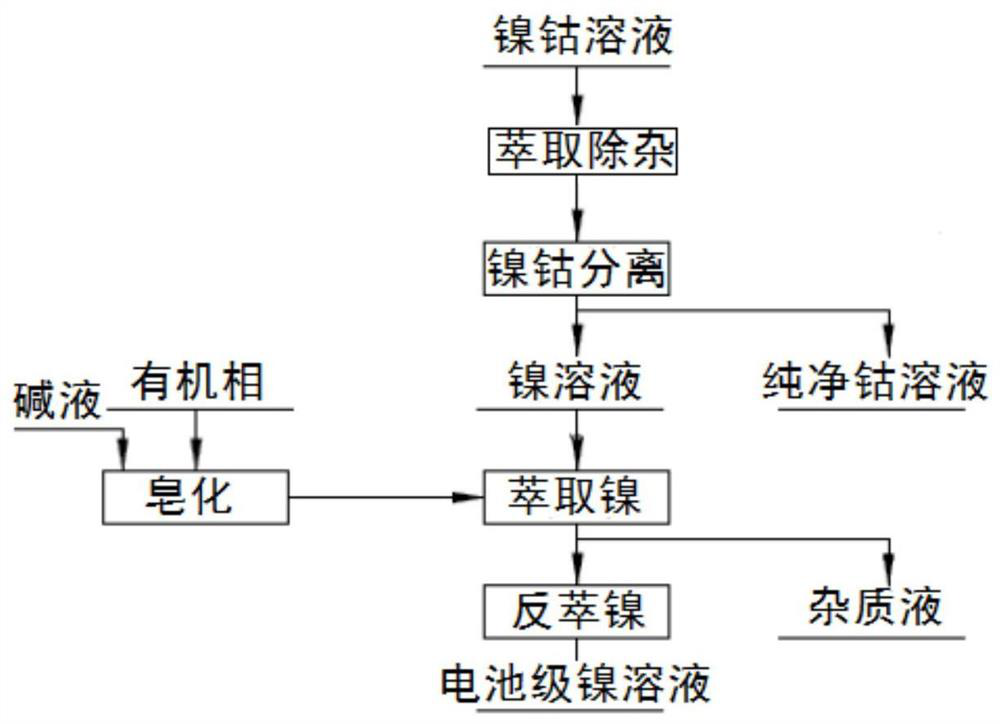

[0021] As described in the background art, the existing battery-grade nickel sulfate solution preparation process has the problems of long process, high process cost, and large acid-base consumption. In order to solve the above-mentioned technical problem, the application provides a kind of preparation method of battery-grade nickel sulfate solution, comprising: using the first inorganic Organic extractant carries out saponification reaction, obtains the first saponification extractant, the second saponification extractant, the 3rd saponification extractant, the 4th saponification extractant; Saponification extraction agent, the 3rd saponification extraction agent, the 4th saponification extraction agent carry out soap conversion reaction, obtain the first soap conversion extraction agent, the 2nd conversion soap extraction agent, the 3rd conversion soap extraction agent, the 4th conversion soap extraction agent; The first soap extractant and the nickel-cobalt sulfate solution...

Embodiment 1

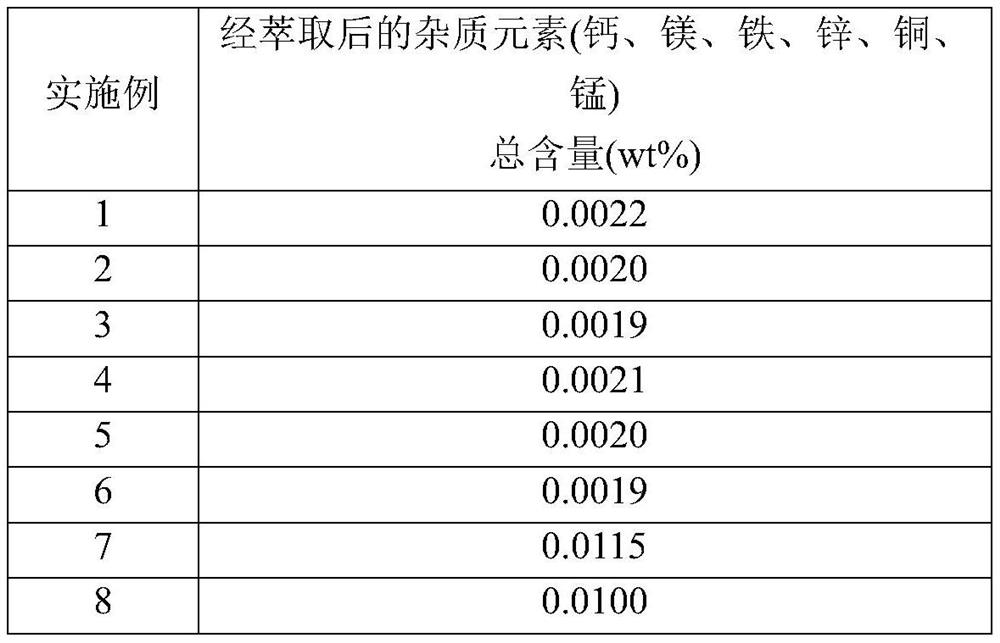

[0042] (1) P204 extract

[0043] The P204 organic extractant that 22L concentration is 25V / V% adopts 0.5L concentration to be that the sodium hydroxide solution of 500g / L carries out saponification, and the nickel sulfate solution that uses 2.6L nickel content through saponification is that the nickel sulfate solution of 90g / L carries out soap turning ( The weight ratio of the nickel element in the nickel sulfate solution to P204 is about 1:22.8), and the high-concentration sodium sulfate solution produced by turning the soap is sent to the evaporation process of the sodium sulfate. The organic extractant after soap conversion and 10L of nickel-cobalt sulfate leaching solution (P204 extraction stock solution) with a nickel content of 90g / L are subjected to countercurrent extraction to remove impurities such as copper, manganese, calcium, zinc, iron, aluminum, etc., to achieve nickel-cobalt sulfate leaching solution. The purpose of leachate purification. The extracted P204 raf...

Embodiment 2

[0051] The difference with Example 1 is: in the P204 extraction process, the saponified extractant uses 2.3L nickel content as the P204 raffinate of 80g / L to carry out soap transfer (the nickel element in the P204 raffinate and the weight of P204 The ratio is about 1:29.0).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com