RPC cover plate for subway evacuation platform and preparation method of RPC cover plate

An evacuation platform and cover plate technology, applied in the field of concrete, can solve the problems of poor toughness, high consumption of RPC cementitious materials, inconsistent hydration process of cementitious materials, etc., to improve toughness and volume stability, and inhibit the generation of microscopic cracks , the effect of inhibiting the expansion of macroscopic crack powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

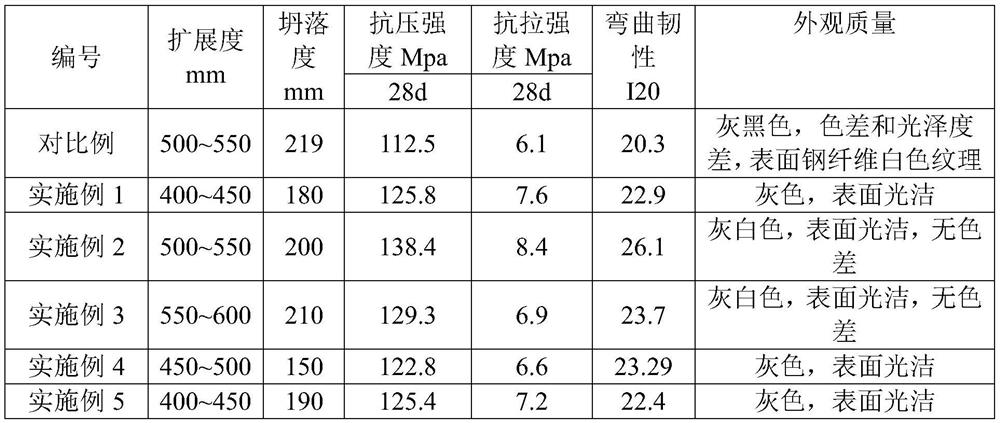

Examples

Embodiment 1

[0050] The raw materials of the RPC cover plate 1 used for the subway evacuation platform include 700 parts by weight of cement, 300 parts of ultrafine mineral powder, 200 parts of silica fume, 800 parts of quartz sand, 100 parts of modified wollastonite powder, polyoxymethylene fiber 10 parts, 30 parts of glass fiber, 0.5 part of polyacrylonitrile fiber, 20 parts of polycarboxylate water reducer, 1 part of brightener and 200 parts of water.

[0051] Among them, the above cement is low C 3 A 52.5 grade ordinary portland cement; the specific surface area of silica fume used is 20000m 2 / kg, SiO 2 The content is 95%; the ultrafine mineral powder used is S95 grade,

[0052] In the above-mentioned quartz sand, the silica content is ≥96%; and the quartz sand is composed of three particle sizes, namely: 0.1mm≤particle size<0.2mm, 0.2mm≤particle size<0.5mm and 0.5mm≤particle size≤ 1.65mm; their weight ratio is 3:5:2.

[0053] The diameter of the polyoxymethylene fiber is 0.2mm,...

Embodiment 2

[0073] The preparation method of this embodiment is basically the same as that of Example 1, and the difference in the raw materials for the RPC cover plate 2 of the subway evacuation platform is:

[0074] The raw materials of the RPC cover plate 2 used for the subway evacuation platform include 750 parts by weight of cement, 100 parts of ultrafine mineral powder, 200 parts of silica fume, 800 parts of quartz sand, 300 parts of modified wollastonite powder, polyoxymethylene fiber 20 parts, 50 parts of glass fiber, 1 part of polyacrylonitrile fiber, 25 parts of polycarboxylate water reducing agent, 1.5 parts of brightener and 210 parts of water.

[0075] Wherein, the above-mentioned modified wollastonite powder is prepared by the following method

[0076] a. Stir the wollastonite powder at a constant temperature of 60°C for 10 minutes;

[0077] b. Then the silane coupling agent is mixed with ethanol to obtain a mixed solution; wherein, the silane coupling agent consumption is ...

Embodiment 3

[0083] The preparation method of this embodiment is basically the same as that of Example 1, and the difference in the raw materials for the RPC cover plate 3 of the subway evacuation platform is:

[0084] The raw materials of the RPC cover plate 3 used for the subway evacuation platform include 600 parts by weight of cement, 100 parts of microbeads, 100 parts of kaolin-based reinforcing agent, 200 parts of silica fume, 900 parts of quartz sand, and 150 parts of modified wollastonite powder. 25 parts of polyoxymethylene fiber, 45 parts of glass fiber, 1.5 parts of polyacrylonitrile fiber, 30 parts of polycarboxylate water reducer, 2 parts of brightener and 190 parts of water.

[0085] Wherein, the above-mentioned modified wollastonite powder is prepared by the following method

[0086] a. Stir the wollastonite powder at a constant temperature of 60°C for 10 minutes;

[0087] b. Then the silane coupling agent is mixed with ethanol to obtain a mixed solution; wherein, the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com