Repairing material for repairing sealing defect and preparation method thereof

A repair material and sealing technology, applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problem of low reliability of plugging technology, increase dimensional stability and strength, and strong oil resistance , to prevent the effect of premature curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

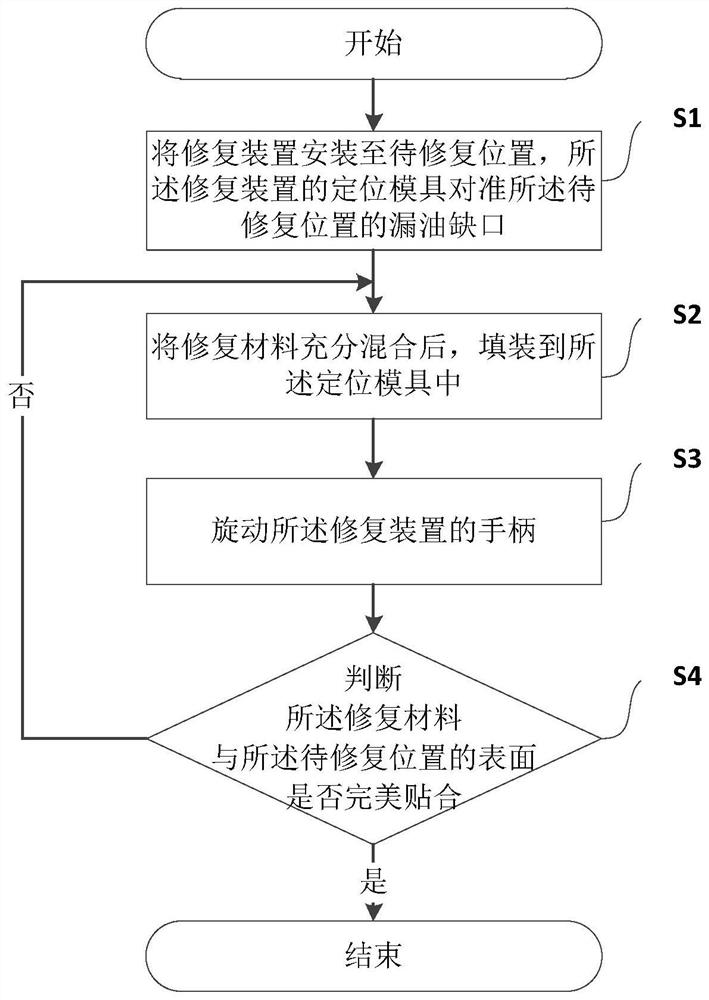

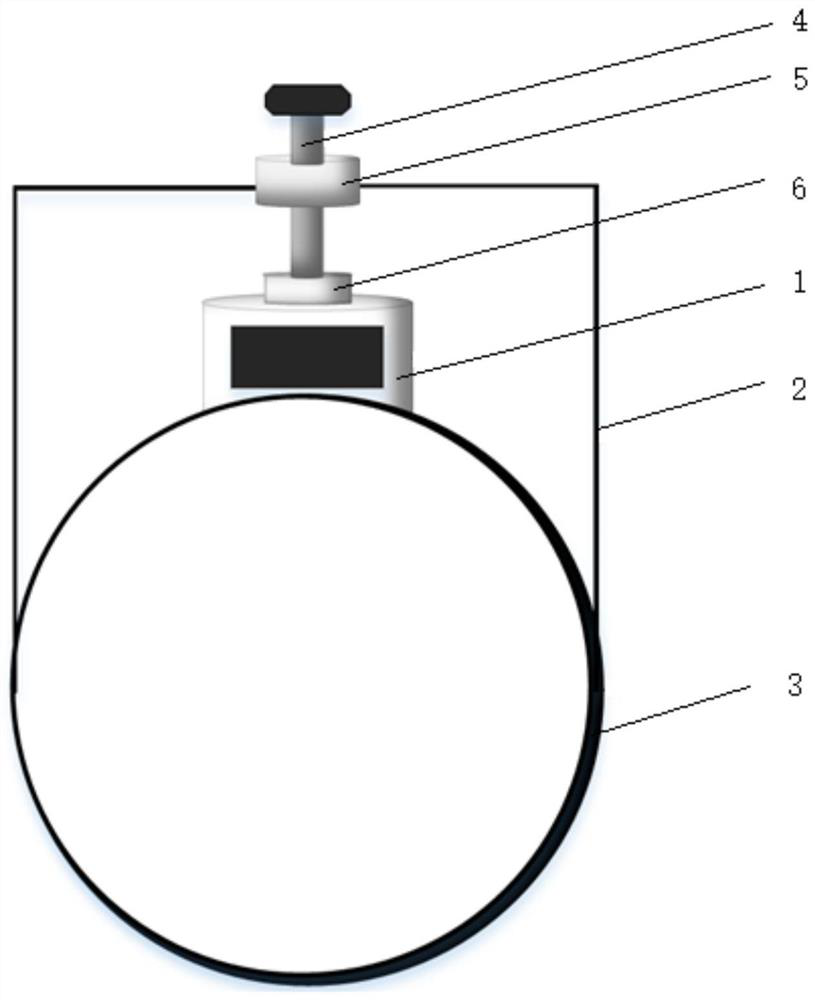

[0039] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention are described below in conjunction with the accompanying drawings The program is described in further detail.

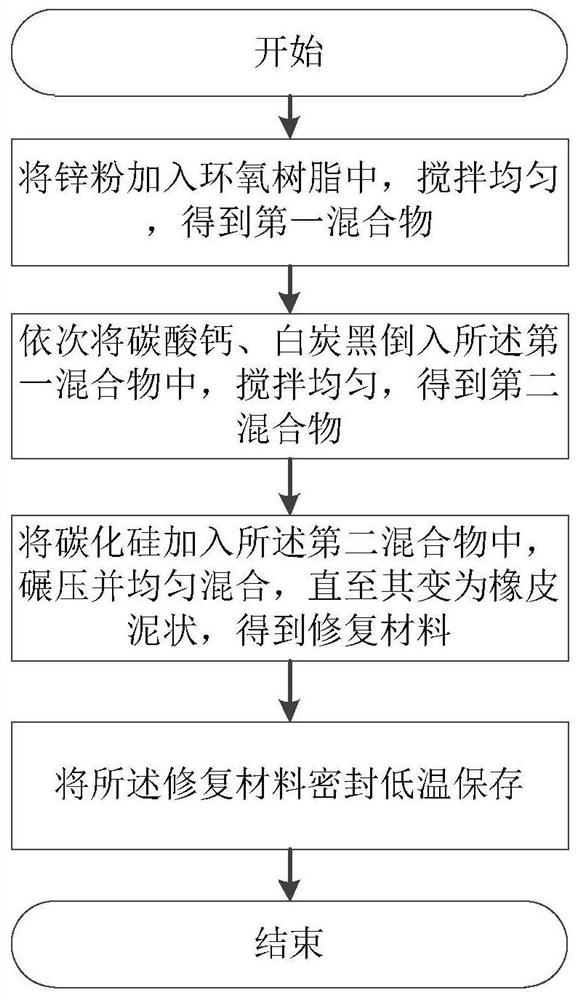

[0040] The application shows a repair material for repairing sealing defects, including: epoxy resin E44, curing agent FS-2B, calcium carbonate, silicon carbide, fumed silica and zinc powder; the composition of the repair material is by weight Calculated, every 100 parts of repair materials include: 10 parts of epoxy resin E44, 10 parts of curing agent FS-2B, 43.5 parts of silicon carbide, 21.5 parts of calcium carbonate, 6.5 parts of fumed silica and 7.5 parts of zinc powder.

[0041] The repair material provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com