Large-scale cell culture method and used microcarrier

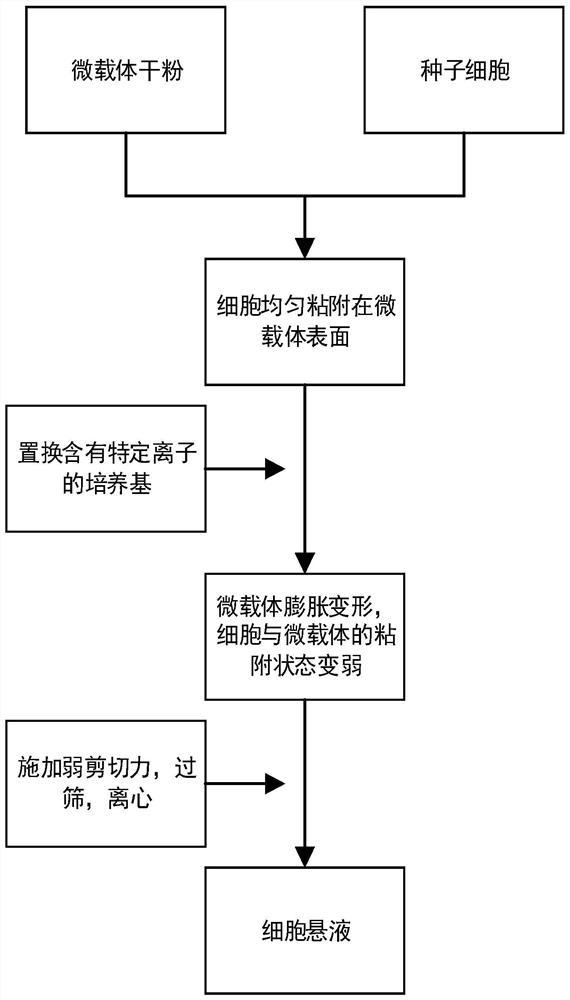

A culture method and microcarrier technology, applied in general culture methods, microcarriers, cell culture supports/coatings, etc., can solve problems such as increased product production costs, increased process flow, and difficulties in large-scale cell culture, achieving Facilitates adhesion and reduces contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

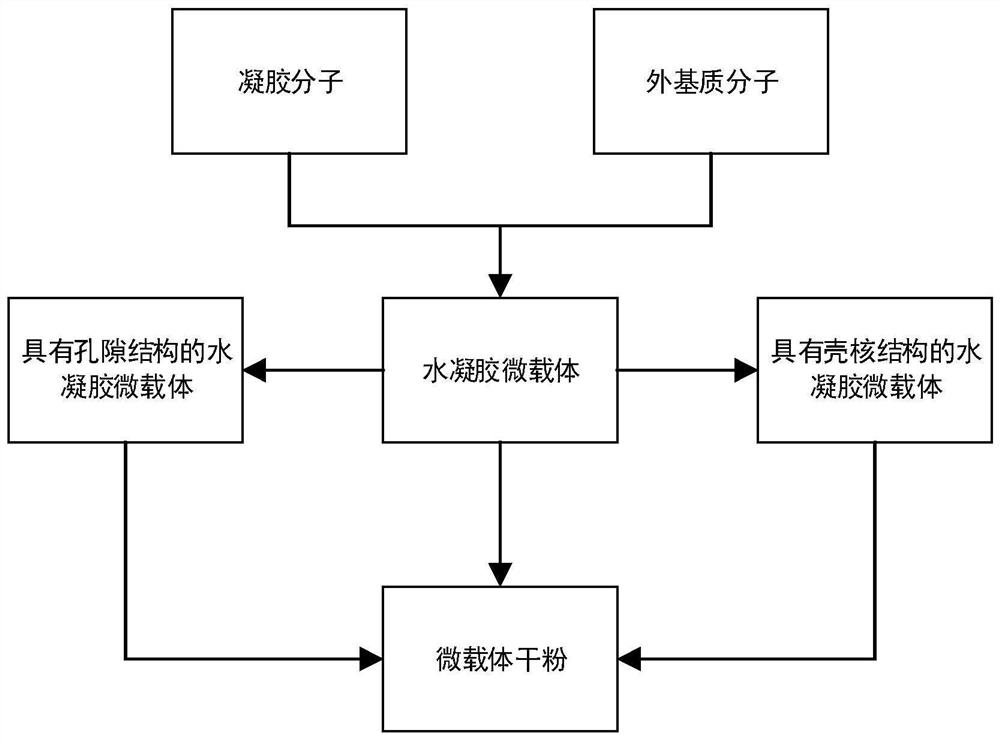

[0040] The preparation method of the microcarrier of the present application is as follows:

[0041] Prepare gel molecule solution and exogenous matrix molecule solution respectively;

[0042] mixing calcium carbonate powder with the gel molecule solution, and then mixing with the exogenous matrix molecule solution to form a premix;

[0043] Promoting the gelation reaction of the premix solution through fluid granulation technology to generate hydrogel microcarriers;

[0044] The hydrogel microcarrier is dried and sterilized to obtain dry powder of the microcarrier.

[0045] Further, the concentration of the gel molecule solution and the exogenous matrix solution affects the size of the hydrogel microcarrier, and those skilled in the art can determine the specific value according to the experimental results, but preferably, the gel in the premix solution The concentration of the molecular solution should be kept above 10g / L to ensure the smooth progress of the gelation react...

Embodiment 1

[0048] refer to figure 1 , the preparation method of the microcarrier is as follows:

[0049] A, solution preparation: concentration 10-50g / L sodium alginate solution; concentration 1-10g / L chitosan solution;

[0050] B. Collagen solution, chitosan solution, matrigel solution, chondroitin sulfate solution or fibronectin solution with a concentration of 2-50g / L are prepared;

[0051] C. Mix the sodium alginate solution prepared in step A with calcium carbonate powder to form a uniform suspension, and then mix it with the collagen solution, chitosan solution, matrigel solution, chondroitin sulfate solution or fibronectin solution prepared in step B One or more of them are uniformly mixed, and the concentration of sodium alginate in the mixture is kept above 10g / L;

[0052] D. The mixed solution prepared in step C is formed into uniform droplets through fluid granulation technology, cross-linked by calcium ions, and combined with temperature changes, a gelation reaction occurs ...

Embodiment 2

[0057] 【1】Prepare sodium alginate solution with a concentration of 30g / L;

[0058] [2] Prepare a collagen solution with a concentration of 5g / L and adjust it to neutral with NaOH;

[0059] 【3】Prepare the gel bath solution, containing calcium chloride (concentration 20g / L) in the gel bath;

[0060] [4] Mix the sodium alginate solution prepared in step [1] with the collagen solution prepared in step [2] in a volume ratio of 2:1;

[0061] [5] The mixture of sodium alginate and collagen prepared in step [4] forms a stable jet under a high-voltage electrostatic field, sprays it into the gel bath prepared in step [3], and keeps the gel bath at 37°C After 30 minutes of gelation reaction, sodium alginate-collagen blended hydrogel microspheres were prepared;

[0062] [6] After the sodium alginate-collagen blended hydrogel microspheres prepared in step [5] are autoclaved, they are dried by a fluidized bed dryer into a microcarrier dry powder for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com