Low-temperature composite heat insulation layer, preparation method thereof and application of low-temperature composite heat insulation layer in vehicle-mounted low-temperature hydrogen storage tank

A thermal insulation layer, multi-layer thermal insulation technology, applied in applications, fixed-capacity gas storage tanks, chemical instruments and methods, etc., can solve problems such as difficulty in ensuring safety, and achieve the purpose of extending service time, reducing production costs, and reducing solid heat transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0082] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0083] In the description of the present invention, it should be noted that the terms "first", "second" and so on are only used for descriptive purposes, and do not indicate or imply relative importance.

[0084] The hollow glass microspheres used ...

Embodiment 1

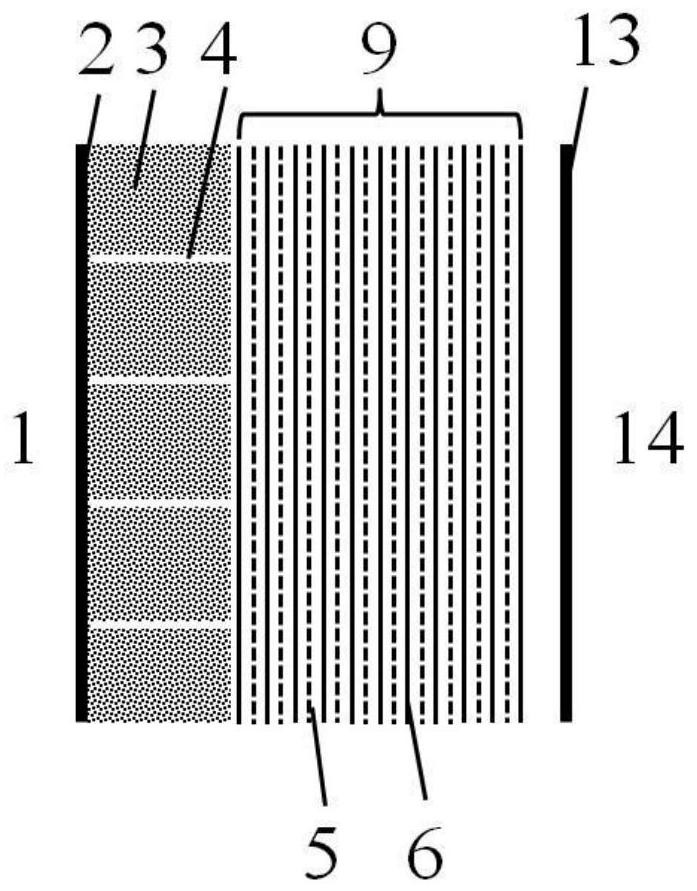

[0087] The thermal insulation structure of the composite thermal insulation layer of this embodiment is as follows: figure 1 As shown, the composite thermal insulation layer of this embodiment is applied to a vehicle-mounted liquid hydrogen (20K) storage tank, and the ambient temperature of the storage tank is 300K, so the temperature at both ends of the composite thermal insulation layer is 20K-300K.

[0088] The vehicle-mounted liquid hydrogen storage tank is a cylindrical storage tank with ellipsoidal heads at both ends. The inner liner of the storage tank stores liquid hydrogen, and the outer shell is a vacuum cover. A composite insulation layer is formed between the inner liner and the outer shell. There are lines that bring hydrogen gas into the combustion chamber of the car engine. In the composite heat insulation layer, a composite heat insulation layer of a 10mm thick hollow microsphere layer and 30 layers of uniform density multilayer heat insulation layers is prepar...

Embodiment 2

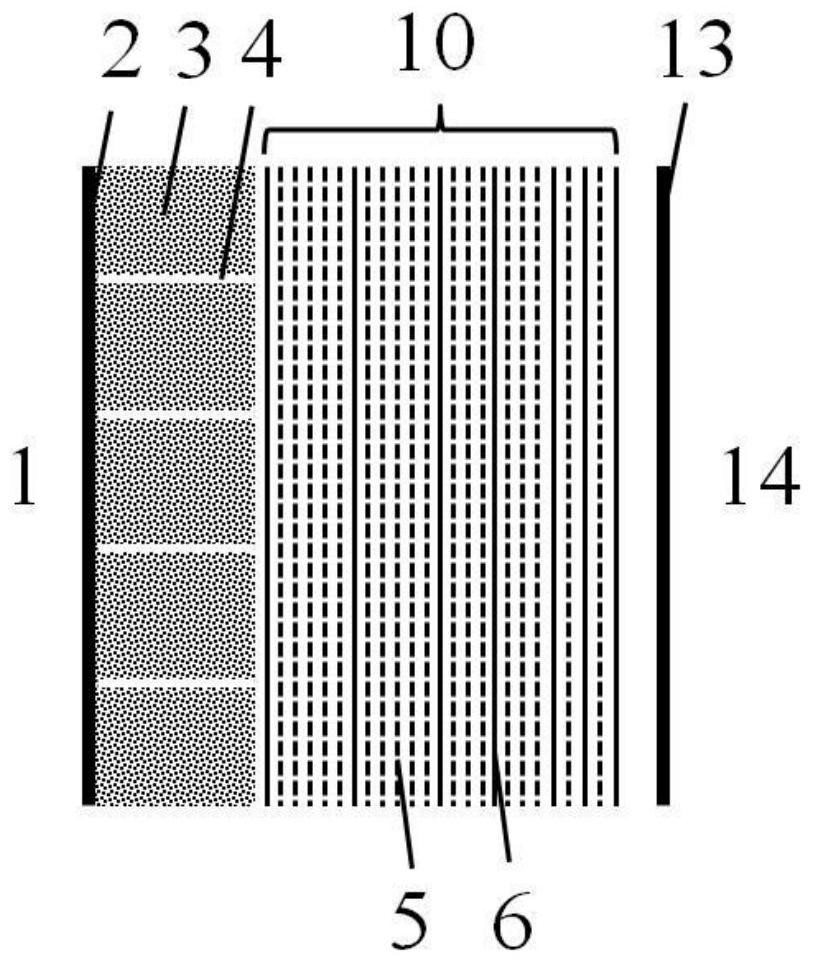

[0107] The thermal insulation structure of the composite thermal insulation layer of this embodiment is as follows: figure 2 As shown, the composite thermal insulation layer of this embodiment is applied to a vehicle-mounted liquid hydrogen (40K) storage tank, and the ambient temperature of the storage tank is 300K, so the temperature at both ends of the composite thermal insulation layer is 40K-300K.

[0108] The vehicle-mounted hydrogen storage tank is the same as in Example 1, except that in the composite insulation layer, a composite insulation layer with a thickness of 20 mm of hollow microsphere layers and 30 layers of variable-density multilayer insulation layers is prepared. The preparation method is as follows:

[0109] 1. Preparation of hollow microsphere layer:

[0110] 1) The hollow microsphere powder is made of hollow glass microspheres, and the density of the hollow glass microspheres is 0.25g / cm 3 , the compressive strength is 5.2MPa, the particle size is 20-8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com