Integrated anti-radiation high-voltage SOI device and manufacturing method thereof

A manufacturing method and anti-radiation technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., to achieve the effects of increasing the opening threshold, improving the anti-single event latch-up ability, and reducing the transport coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

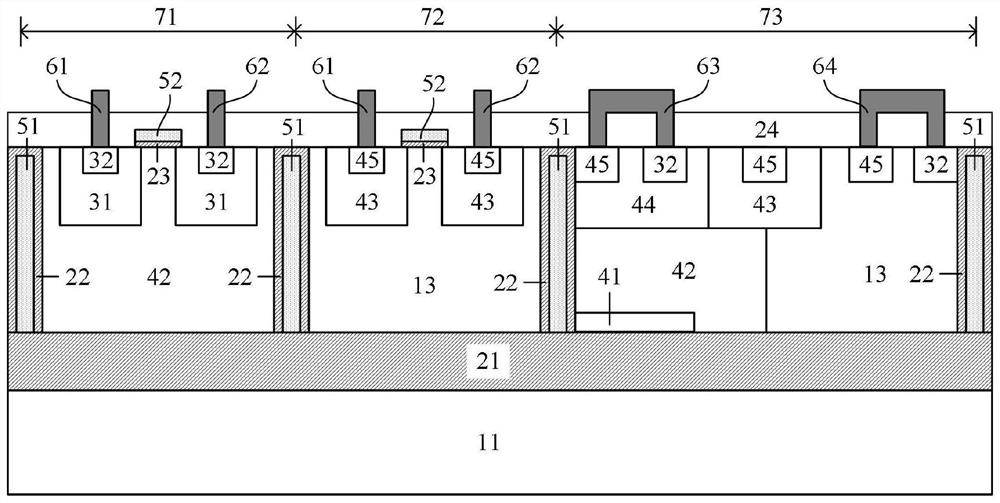

[0040] The invention provides an integrated anti-radiation high-voltage SOI device, the structure of which is as follows figure 1 As shown, it includes a P-type substrate 11, a buried oxide layer 21, and an N-type epitaxial layer 13 formed in sequence; the surface of the N-type epitaxial layer 13 is provided with a high-voltage NMOS device 71, a high-voltage PMOS device 72, and a high-voltage ESD device 73; The integrated radiation-resistant high-voltage SOI device also includes an isolation oxide layer 22, a gate oxide layer 23, a pre-metal dielectric layer 24, a first P-type doped region 41, a second P-type doped region 42, and a third P-type doped region. 43. Fourth P-type doped region 44, fifth P-type doped region 45, first N-type doped region 31, second N-type doped region 32, polysilicon 51, polysilicon gate electrode 52, source metal Electrode 61, drain metal electrode 62, anode metal electrode 63, cathode metal electrode 64; the first N-type doped region 31 is set in t...

Embodiment 2

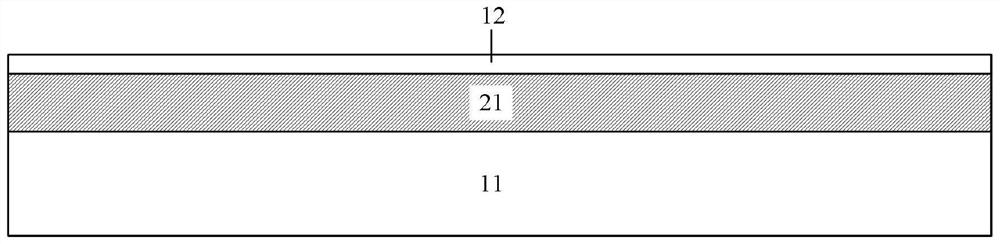

[0042] The invention also provides a method for manufacturing an integrated radiation-resistant high-voltage SOI device, which is processed and prepared on a silicon-on-insulator material, such as figure 2 As shown, the silicon-on-insulator has a P-type substrate 11, a buried oxide layer 21 and a top layer of silicon 12 stacked sequentially from bottom to top, including the following steps:

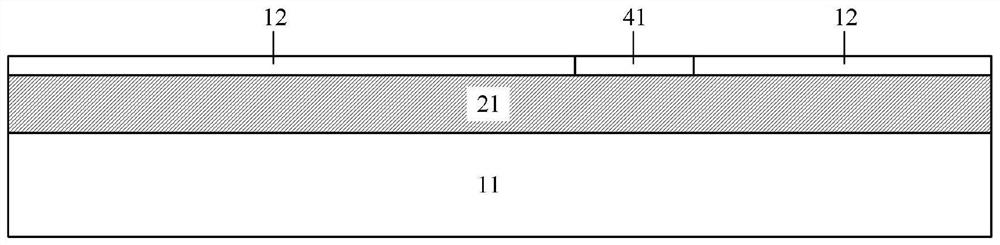

[0043] Such as image 3 As shown, the ion implantation process is used to implant P-type impurities on the top layer silicon 12 to form the first P-type doped region 41; the implantation dose of the first P-type doped region 41 is 1E13~1E15cm -2 ;

[0044] Such as Figure 4 As shown, an N-type epitaxial layer 13 is formed on the buried oxide layer 21 by using an epitaxial process; the N-type epitaxial layer 13 covers the first P-type doped region 41;

[0045] Such as Figure 5 As shown, a deep silicon trench is etched on the N-type epitaxial layer 13 by photolithography and etching p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com