Preparation method of perovskite thin film and perovskite LED

A perovskite and thin film technology, applied in the field of optoelectronic materials, can solve the problems of poor film quality and weak luminous intensity, and achieve the effects of high brightness, smooth surface and improved lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

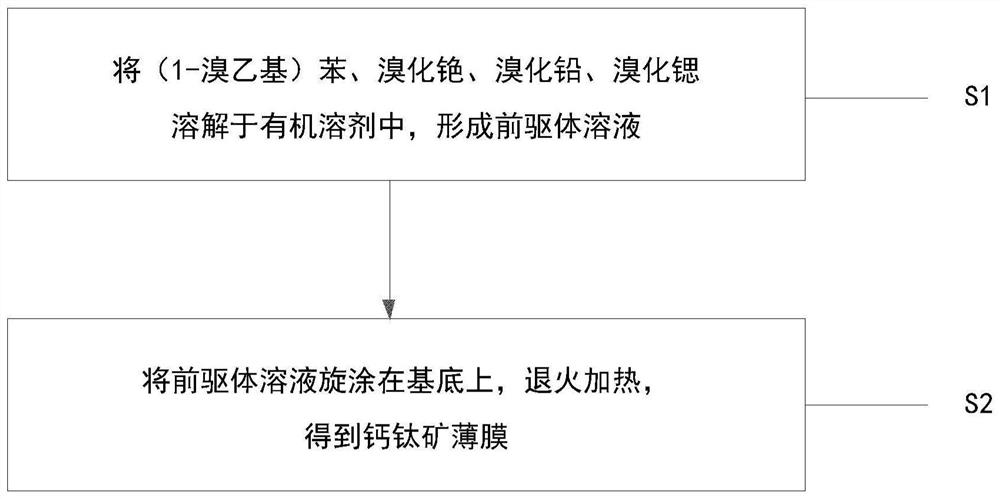

[0029] Embodiments of the present disclosure provide a method for preparing a perovskite thin film, please refer to figure 1 , including: S1, dissolving (1-bromoethyl)benzene, cesium bromide, lead bromide, and strontium bromide in an organic solvent to form a precursor solution; S2, spin-coating the precursor solution on the substrate, annealing Heating to obtain a perovskite film.

[0030] (1-Bromoethyl) benzene, also known as PEABr, has the following structural formula as formula I:

[0031]

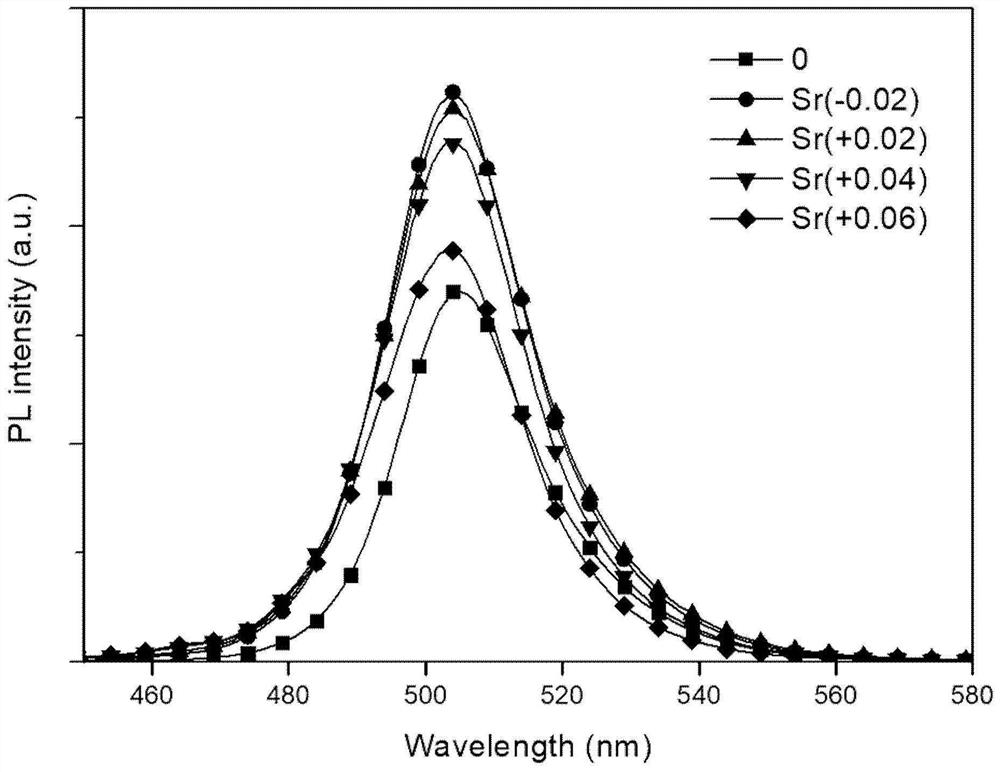

[0032] Due to the addition of PEABr, a quasi-two-dimensional perovskite structure is formed, and the size of the perovskite crystal decreases; with the increase of PEAr, the proportion of the quasi-two-dimensional perovskite structure with a larger band gap increases in the perovskite film , the energy transition of excitons from a large bandgap crystal structure to a low bandgap crystal structure is more likely to occur, non-radiative recombination is suppressed, radiative recombi...

Embodiment 1

[0074] A method for preparing a perovskite film with high luminous intensity, the steps are as follows:

[0075] (1) Preparation of perovskite precursor solution (ie S1): the molar ratio is PEABr: CsBr: PbBr 2 :SrBr 2 =1:1:A:B was dissolved in dimethyl sulfoxide, stirred evenly to prepare a clear and transparent perovskite precursor solution, wherein the value of A was 1.52, the value of B was 0, and the value of dimethyl sulfoxide The volume is 1mL, PbBr 2 The molar mass is 0.5mM.

[0076] (2) Preparation of PEDOT:PSS layer: PEDOT:PSS and anhydrous isopropanol are prepared in a volume ratio of 10:1 to form a PEDOT:PSS mixed solution, stirred evenly at low temperature, and filtered using a water-based filter with a pore size of 0.22 or 0.45 μm Does not dissolve small particles.

[0077] The spin coating of PEDOT:PSS layer is divided into three stages, the first stage rotation speed is 1200rpm, time is 12s, acceleration 500rpm / s; The second stage rotation speed is 2000rpm, ...

Embodiment 2

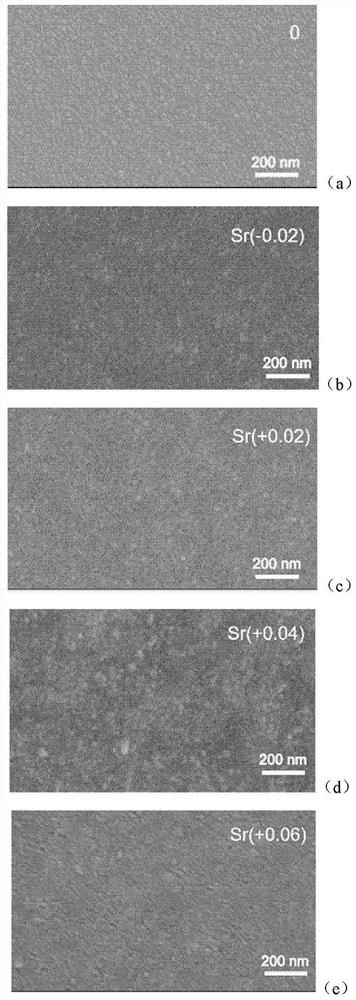

[0082] The difference with Example 1 is: in step (1), the value of A in the perovskite thin film precursor solution is prepared to be 1.46, the value of B is 0.06, and the value of PbBr 2 The molar mass is 0.48mM, and others are all the same as in Example 1. We define this sample label as Sr(-0.02), see figure 2 Middle (b) diagram.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com