Preparation of ionic liquid slow-release agent and method for purifying arsenic and heavy metal wastewater by using ionic liquid slow-release agent

A technology of ionic liquids and heavy metals, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of high cost, high harm, low efficiency, etc., achieve high utilization rate, reduce harm, and reduce use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

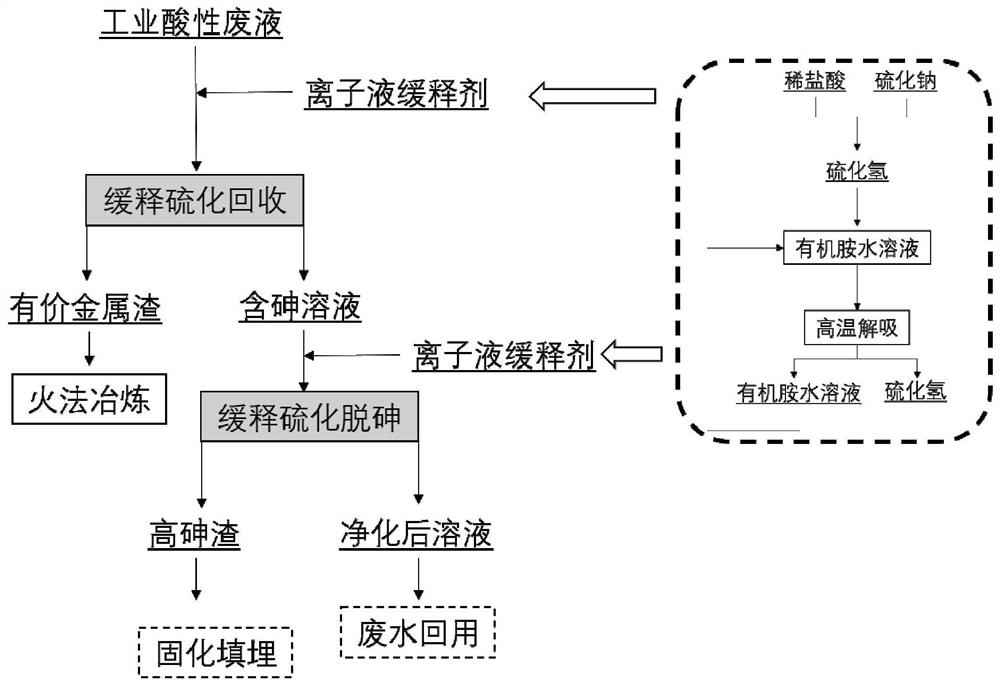

[0028] Utilize this process method to process certain copper smelting dirty acid waste water, concrete steps are as follows: get a certain amount of dirty acid waste water (H 2 SO 4 content of 8%, copper content of 0.5g / L, arsenic content of 2g / L), the configuration concentration is 35% of dilute hydrochloric acid dripped into 1.2mol / L sodium sulfate solution at 10mL / min to produce hydrogen sulfide, and 35% The ionic liquid slow-release agent was synthesized from the N-methyldiethanolamine solution, and the synthesis conditions were as follows: synthesis pressure 4MPa, temperature 25°C, synthesis time 45min; desorption oil bath temperature was controlled at 110°C, desorption gas was slowly passed into dirty acid for vulcanization Reaction, the reaction temperature is 60°C, the stirring speed is 300r / min, and the oxidation-reduction potentiometer is used to monitor the potential of the reaction change. When the oxidation-reduction potential decreases from the initial 450mV to 2...

Embodiment 2

[0031] Utilize this technological method to process certain copper smelting soot leach liquor, concrete steps are as follows: get a certain amount of leach liquor (H 2 SO 4content of 7%, copper content of 20g / L, arsenic content of 8g / L), the configuration concentration is 40% dilute hydrochloric acid dripped into 1.2mol / L sodium sulfate solution at 10mL / min to produce hydrogen sulfide, and 40% of Synthesis of ionic liquid sustained-release agent with N-methyldiethanolamine solution, the synthesis conditions are: synthesis pressure 3MPa, temperature 25°C, synthesis time 60min; desorption oil bath temperature is controlled at 120°C, desorption gas is passed into dirty acid for vulcanization reaction, The reaction temperature is 40°C, the stirring speed is 300r / min, and the oxidation-reduction potentiometer is used to monitor the potential of the reaction change. When the oxidation-reduction potential decreases from the initial 447mV to 262mV, it means that the copper ions are ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com