Photovoltaic fluorine-containing wastewater recycling method

A technology of recycling and wastewater, applied in chemical instruments and methods, calcium/strontium/barium fluoride, water pollutants, etc., can solve the problems of waste, residual lime residue, solid waste fluorine resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

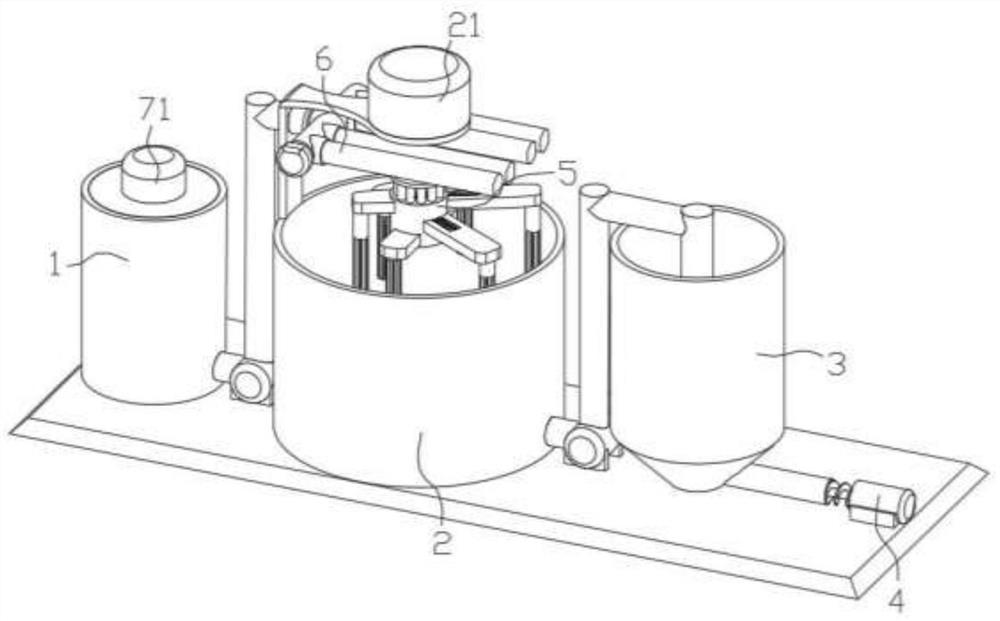

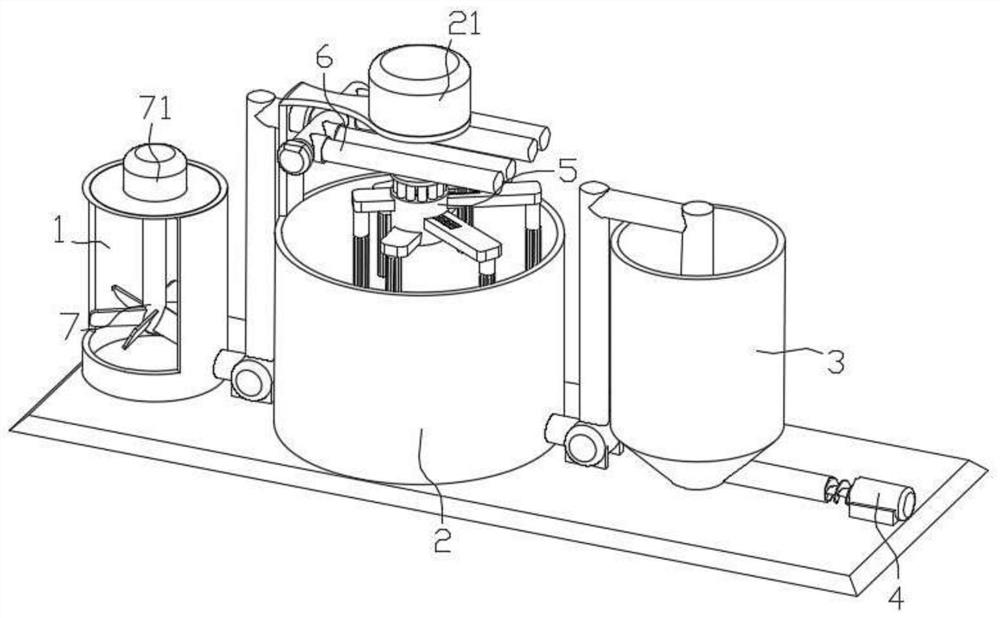

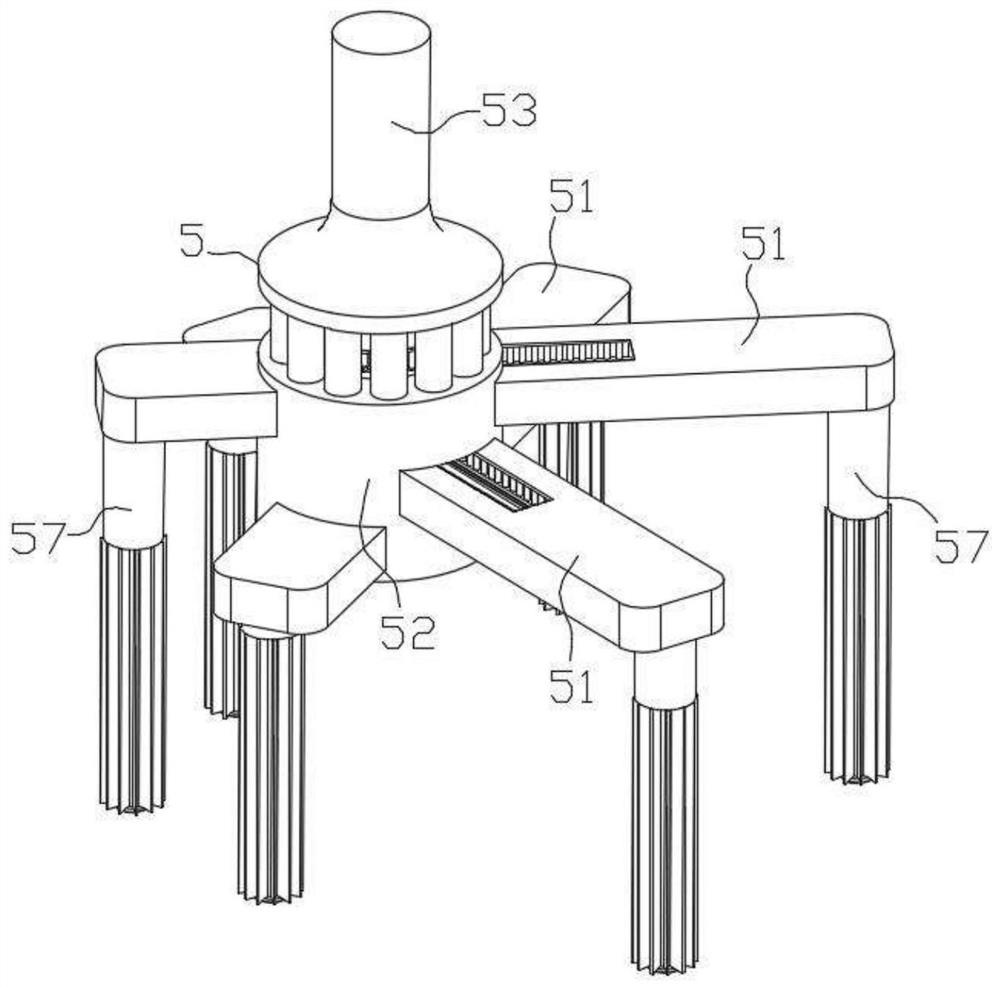

Image

Examples

Embodiment 1

[0044] S1: Configure the calcium chloride reaction solution for the reaction and treatment of photovoltaic fluorine-containing wastewater through the calcium chloride configuration tank, and wait for use; the preparation of the calcium chloride reaction solution is 74.5g / 100mL saturated calcium chloride solution;

[0045] S2: The calcium chloride reaction solution is added dropwise to the reaction pool in multiple points for mixed reaction with the photovoltaic fluorine-containing wastewater under acidic conditions of pH=1~2, and the dosage of the calcium chloride reaction solution is according to Ca:F=1: The molar ratio of 2 is added, and the stirring speed is 500rpm to obtain the reaction mixture; the calcium fluoride seed crystals accounting for 15g / L of photovoltaic fluorine-containing wastewater injection are also added in the calcium chloride reaction solution; by adding the above-mentioned dosage The strong agent can effectively promote the output of calcium fluoride pre...

Embodiment 2

[0048] This example is basically the same as Example 1, except that the stirring speed of the calcium chloride reaction liquid and photovoltaic fluorine-containing wastewater is different when they are mixed dropwise, specifically as follows: the stirring speed is 200 rpm.

Embodiment 3

[0050] This example is basically the same as Example 1, except that the stirring speed of the calcium chloride reaction liquid and photovoltaic fluorine-containing wastewater is different when they are mixed dropwise, specifically as follows: the stirring speed is 1000 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com