Lightweight concrete heat preservation and sound insulation wall and preparation method thereof

A light-weight concrete and sound-insulation technology, applied in thermal insulation, walls, sound insulation, etc., can solve problems such as wall hollowing and cracking, high maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

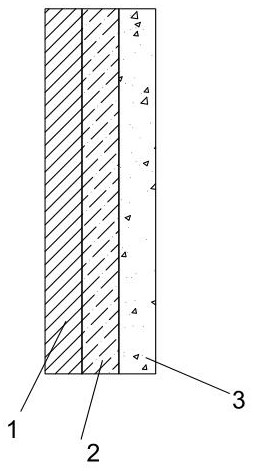

[0024] refer to figure 1 , a light-weight concrete thermal insulation and sound insulation wall disclosed in this embodiment includes a base wall surface 1, a layer of base layer 2 is coated on the base wall surface 1, and a layer of layer 3 is coated on the base layer 2, the described The bottom layer 2 includes raw materials according to the following proportions: 60-70 parts of high-strength gypsum, 10-20 parts of rubber, 5-10 parts of perlite, 0.5-2 parts of polystyrene particles and 0.2-1 part of modified additives. The above surface layer 3 includes raw materials according to the following proportions: 20-30 parts of high-strength gypsum, 10-15 parts of cement, 10-20 parts of sand, 20-30 parts of cinder and 0.2-1 part of additives. The modified additives include modified fillers and filled with one or more binders, admixtures and nano-additives, and the additives include one or more of silicon oxide, titanium oxide, calcium oxide and binders, The modified filler is a mo...

Embodiment 2

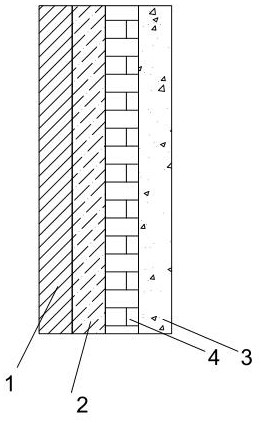

[0035] refer to figure 2 , a light-weight concrete thermal insulation and sound insulation wall disclosed in this embodiment, further, a polystyrene foam thermal insulation layer 4 is coated between the bottom layer 2 and the surface layer 3, and the polystyrene foam thermal insulation layer 4 The raw material is air-entrained lightweight aggregate concrete with a bulk density of 1150-1250kg / m 3 .

Embodiment 3

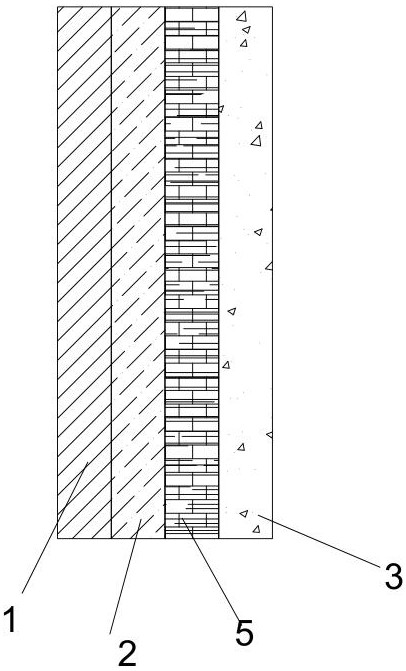

[0037] refer to image 3 , a light-weight concrete thermal insulation and sound-insulating wall disclosed in this embodiment, further, a light steel keel 5 is arranged between the bottom layer 2 and the surface layer 3, and the light steel keel 5 is filled with foamed concrete material, the described The foam concrete material includes high-strength gypsum, ceramsite, fly ash and foaming agent, among which, the mass proportion of ceramsite is 15%-30%; the mass proportion of fly ash is 5%-15%; the mass proportion of high-strength gypsum The proportion is 20%-60%, and the mass proportion of the blowing agent is 20%-35%.

[0038] Further, the mass proportion of the ceramsite is 15%, the mass proportion of fly ash is 10%, the mass proportion of high-strength gypsum is 50%, and the mass proportion of the foaming agent is 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap