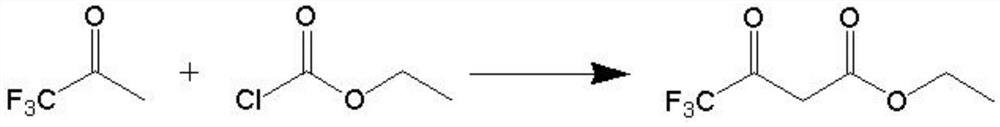

Synthetic method of ethyl 4,4,4-trifluoroacetoacetate

A technology of ethyl trifluoroacetoacetate and its synthesis method, which is applied in the field of synthesis of ethyl 4,4,4-trifluoroacetoacetate, and can solve the problems of multiple side reactions and potential safety hazards in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

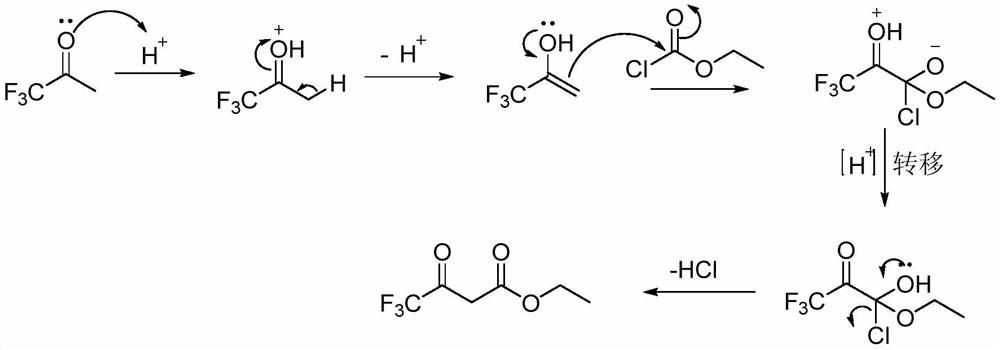

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 114.3g (1.0mol) of trifluoroacetone and 228.6g of toluene and stir them evenly in a mixing bottle as liquid A; 110.2g (1.0mol) of ethyl chloroformate (content 98.5%) is used as liquid B;

[0032] (2) Set the temperature of the pipeline reactor to 50°C, the pressure to 0.5MPa, the pump A to set the flow rate at 8ml / min, and the pump B to set the flow rate to 2ml / min. After reaching the set temperature, open the tail gas exhaust valve and the hydrogen chloride gas inlet valve. Introduce hydrogen chloride gas; turn on pump A to feed the mixture of trifluoroacetone and toluene, and turn on pump B to feed ethyl chloroformate;

[0033] (3) after 20min, take a sample and detect 0.49% of the residual ethyl chloroformate in the reaction liquid at the outlet of the reactor, and the reaction is qualified;

[0034] (4) After the reaction is over, the reaction solution undergoes an atmospheric rectification to recover toluene and a small amount of residual raw materials, a...

Embodiment 2

[0036] (1) Weigh 125.7g (1.1mol) of trifluoroacetone and 377.1g of cyclohexane and stir them evenly in a mixing bottle as liquid A; 110.2g (content 98.5%) (1.0mol) of ethyl chloroformate as liquid B;

[0037] (2) Set the temperature of the pipeline reactor to 70°C, the pressure to 0.6MPa, the flow rate of pump A to 9.5ml / min, and the flow rate of pump B to 1.5ml / min. After reaching the set temperature, open the tail gas exhaust valve and hydrogen chloride gas intake Valve, feed hydrogen chloride gas; open pump A to enter the mixed solution of trifluoroacetone and cyclohexane, open pump B to enter ethyl chloroformate;

[0038] (3) After 20min, take a sample and detect 0.45% of the residual ethyl chloroformate in the reaction liquid at the outlet of the reactor, and the reaction is qualified;

[0039] (4) After the reaction is over, the reaction solution undergoes a rectification at atmospheric pressure to recover cyclohexane and a small amount of residual raw materials, and the...

Embodiment 3

[0041] (1) Weigh 125.7g (1.1mol) of trifluoroacetone and 377.1g of cyclohexane and stir them evenly in a mixing bottle as liquid A; 110.2g (1.0mol) of ethyl chloroformate (content 98.5%) is used as liquid B;

[0042] (2) Set the temperature of the pipeline reactor to 80°C, the pressure to 0.7MPa, set the flow rate of pump A to 9.5ml / min, and the flow rate of pump B to 1.5ml / min, and open the tail gas exhaust valve and hydrogen chloride gas intake after reaching the set temperature Valve, feed hydrogen chloride gas; open pump A to enter the mixed solution of trifluoroacetone and cyclohexane, open pump B to enter ethyl chloroformate;

[0043] (3) After 20min, take a sample and detect 0.2% of the residual ethyl chloroformate in the reaction liquid at the outlet of the reactor, and the reaction is qualified;

[0044] (4) After the reaction is over, the reaction solution undergoes a rectification at atmospheric pressure to recover cyclohexane and a small amount of residual raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com