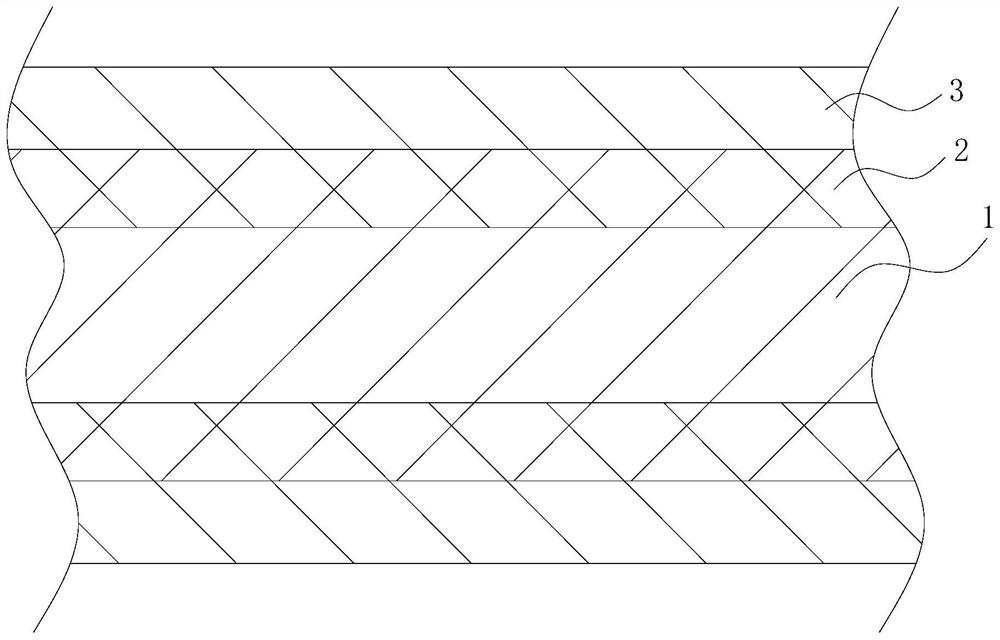

Sandwich aluminum-based printed circuit board laminating method

A technology for printed circuit boards and aluminum substrates, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., and can solve problems such as poor performance and stability, and high production costs of aluminum substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

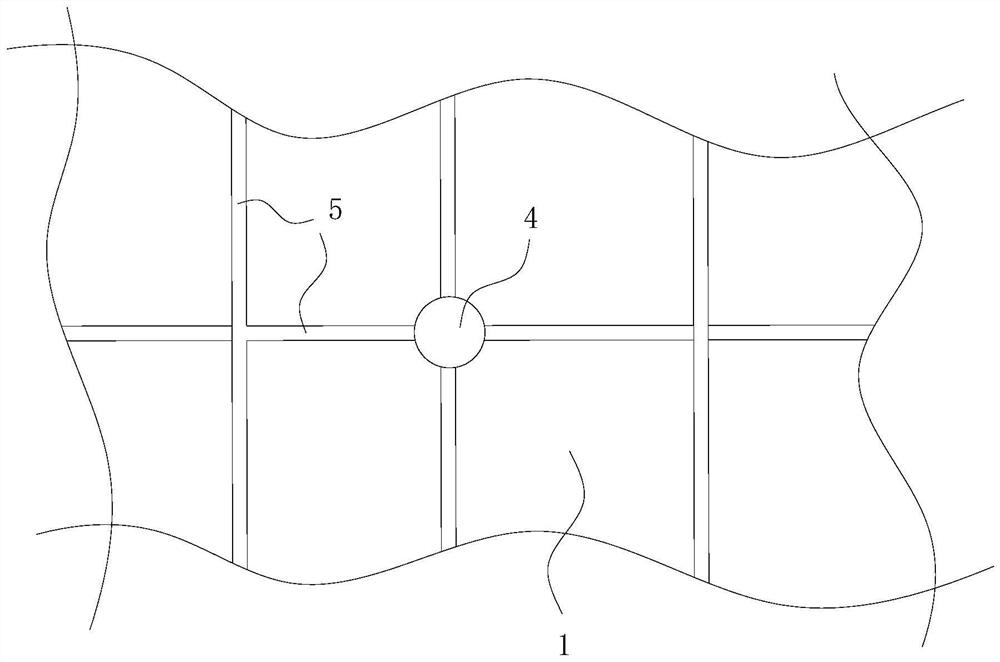

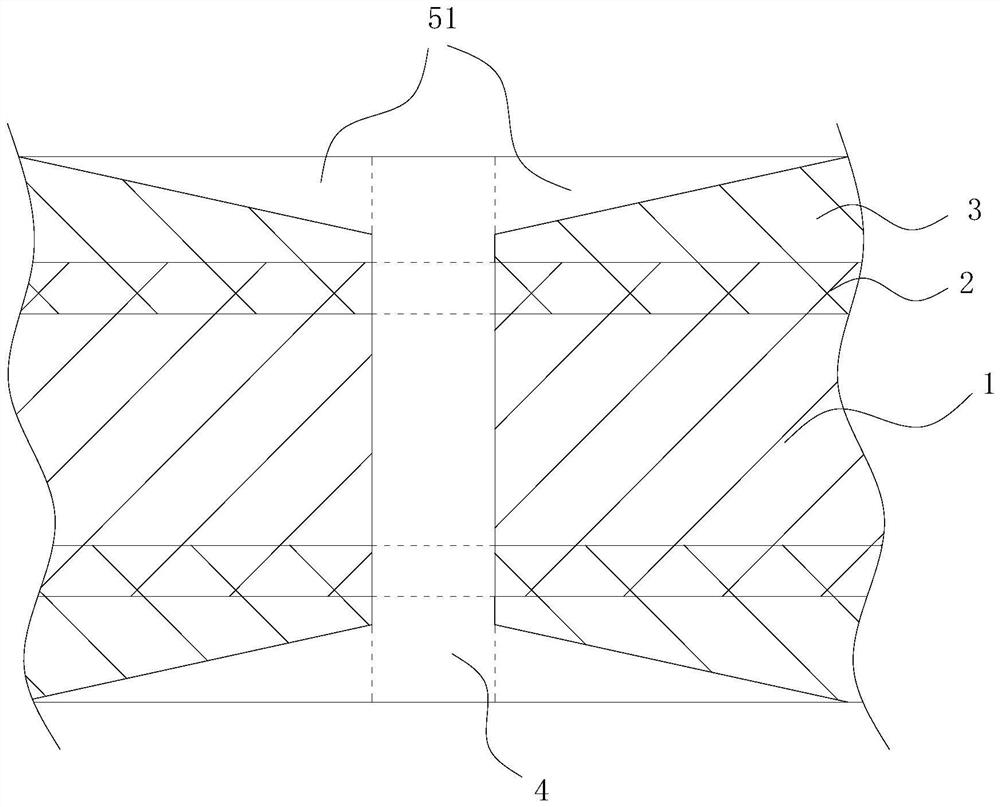

[0039] As an embodiment of the present invention, after the aluminum substrate 1 is ultrasonically cleaned, the surface of the aluminum substrate 1 is subjected to surface treatment; during the surface treatment, the aluminum substrate 1 is burnt with a flame spray gun; the surface treatment During the process, the temperature of the flame spray gun is 665-670°C; the surface treatment time is 3-5S; when the aluminum substrate 1 is surface treated, the aluminum substrate 1 is in a nitrogen atmosphere;

[0040] During work, by burning the aluminum substrate 1 with a flame, the burrs generated on the surface of the aluminum substrate 1 and the inner wall of the through hole 4 can be melted and removed when the aluminum substrate 1 is punching the groove 5 and drilling the through hole 4, so as to avoid There are burrs on the surface of the aluminum substrate 1, which affect the performance of the laminated circuit board. At the same time, avoid the reduction of the pressure resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com