Stacked three-dimensional rocking chair type capacitive deionization device and deionization method

A capacitive deionization and stacking technology, which is applied in the field of water treatment, can solve the problems of low efficiency and small processing capacity, and achieve the effects of large processing capacity, enlarged adsorption space, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] As a further illustration, in order to obtain an electrode material that can improve the adsorption performance of the capacitive deionization device, the preparation method of the Ag@C three-dimensional electrode material includes the steps:

[0065] S1, mix Aspergillus niger and water according to the solid-to-liquid ratio of 1-5g: 50ml to obtain Aspergillus niger solution;

[0066] S2, adding 1-3g of m-phenylenediamine and 0.5-5g of ammonium persulfate to the Aspergillus niger solution in sequence for reaction, and after 1-8h of reaction, suction filtration is formed, and then the substance obtained after the suction filtration is subjected to Freeze-dry to obtain poly-m-phenylenediamine@Aspergillus niger composite material;

[0067] S3, placing the poly-m-phenylenediamine@Aspergillus niger composite material in 500-3000ppm of AgNO 3 standing in the solution, followed by drying treatment and carbonization treatment at 400-1000° C. to obtain the Ag@C three-dimensiona...

Embodiment 1

[0082] The material preparation of the Ag@C three-dimensional electrode: put 3g of Aspergillus niger in a 100mL beaker, add 50mL of deionized water, then add 2g of m-phenylenediamine, and then add 2.202g of ammonium persulfate, react for 3 hours and then filter and form. After freeze-drying, the resulting poly-m-phenylenediamine@Aspergillus niger composite was placed in 2000ppm AgNO 3 Stand in the solution for 24 hours, dry at 60°C, and then carbonize at 800°C to obtain the Ag@C three-dimensional electrode material.

[0083] The internal structure and element distribution of the prepared Ag@C three-dimensional electrode material can be referred to Figure 9 (converted from the color picture) to understand, it can be seen that its interior is a filamentous structure and has large gaps for ion adsorption; in addition, the specific values of the element distribution of the Ag@C three-dimensional electrode material are as follows:

[0084]

[0085]

Embodiment 2

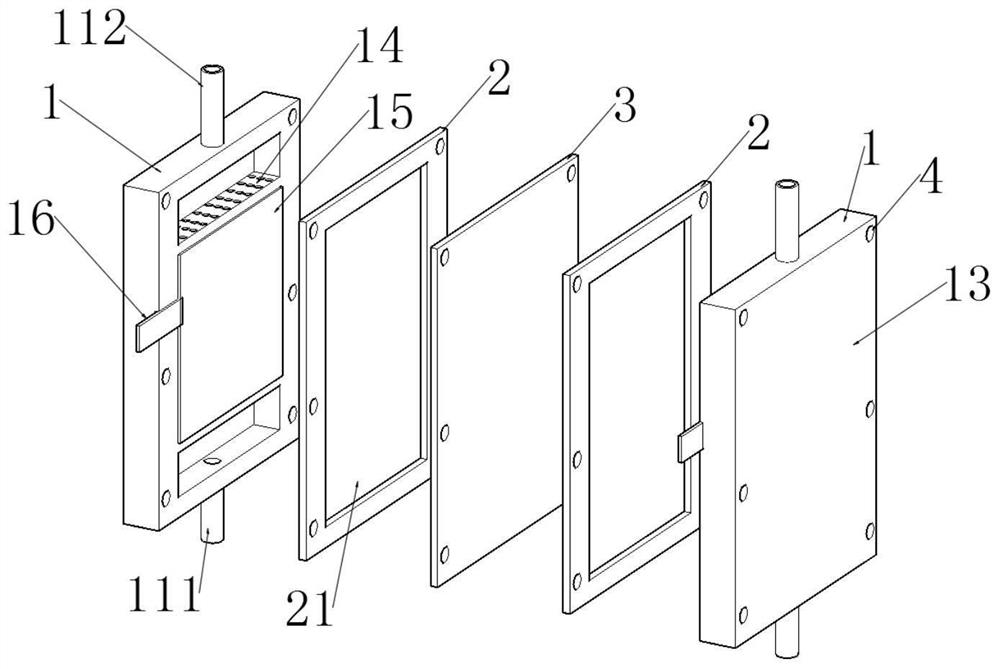

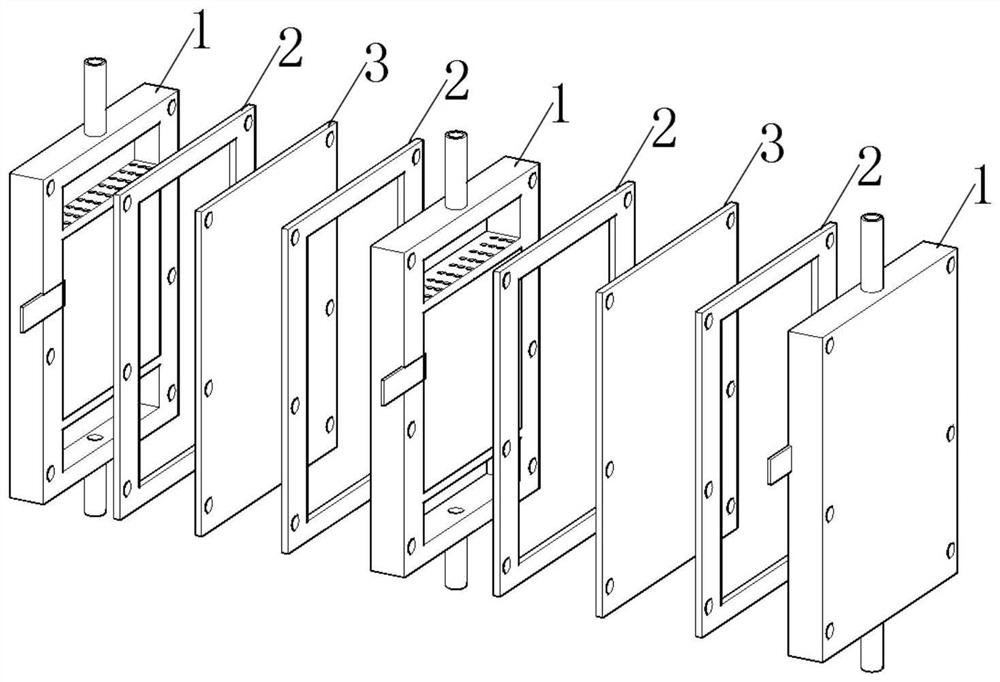

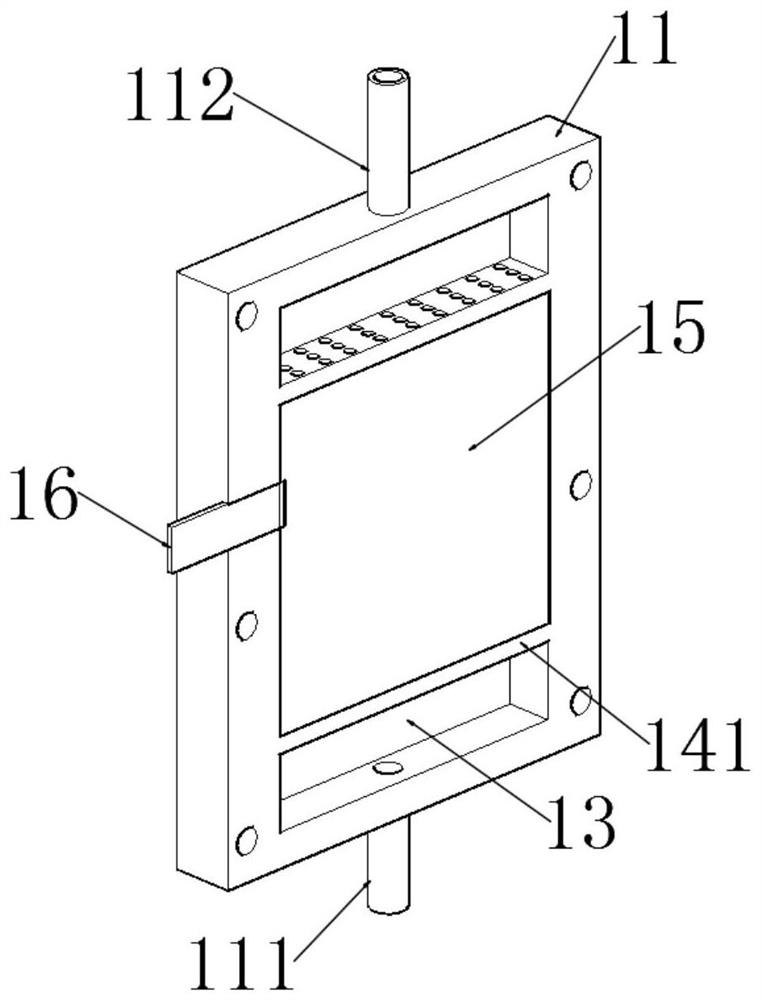

[0087] Such as figure 1 , image 3 , Figure 4 and Figure 7 As shown, a stacked three-dimensional rocking chair capacitive deionization device includes a main body and accessories. The main body includes a chamber mechanism 1 , a cation exchange membrane 3 , a current collector 16 , and a silica gel gasket 2 .

[0088] Wherein, the chamber mechanism 1 further includes two terminal chamber mechanisms located at both ends of the stacking direction. In addition, the above-mentioned accessories are mainly fixed installation parts, including silicone tubes and screws.

[0089] Set the silica gel gasket 2 on the right side of the left terminal chamber mechanism, set the silica gel gasket 2 on the left side of the right terminal chamber mechanism, and set the commercial cation exchange membrane 3 between the two silica gel gaskets 2; Wherein, the size of each terminal chamber mechanism, each silica gel gasket 2 and cation exchange membrane 3 is the same, and the outer edges are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com