Complete equipment for repairing and reinforcing shield subway tunnel segments

A technology for tunnel segments and complete sets of equipment, which is applied in the field of complete sets of equipment for shield tunnel segment repair and reinforcement, can solve the problems of high construction cost, low construction efficiency, and large construction difficulties, and achieve the goal of improving construction efficiency and mechanical automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

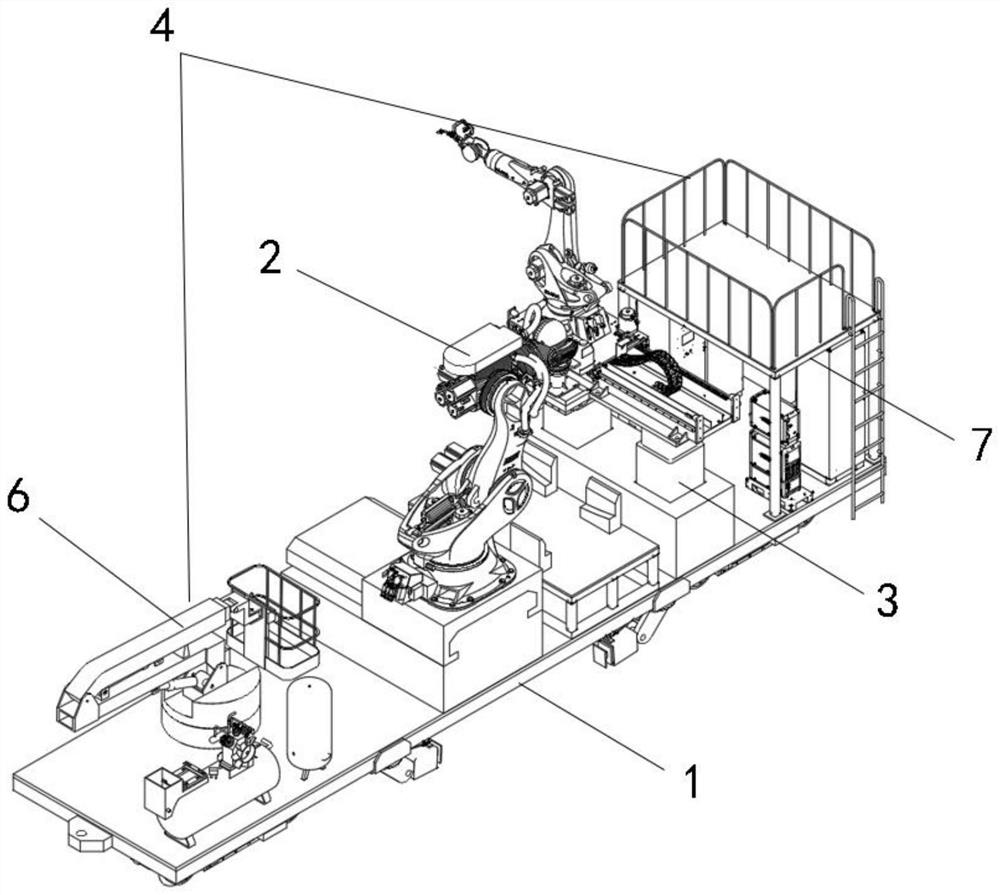

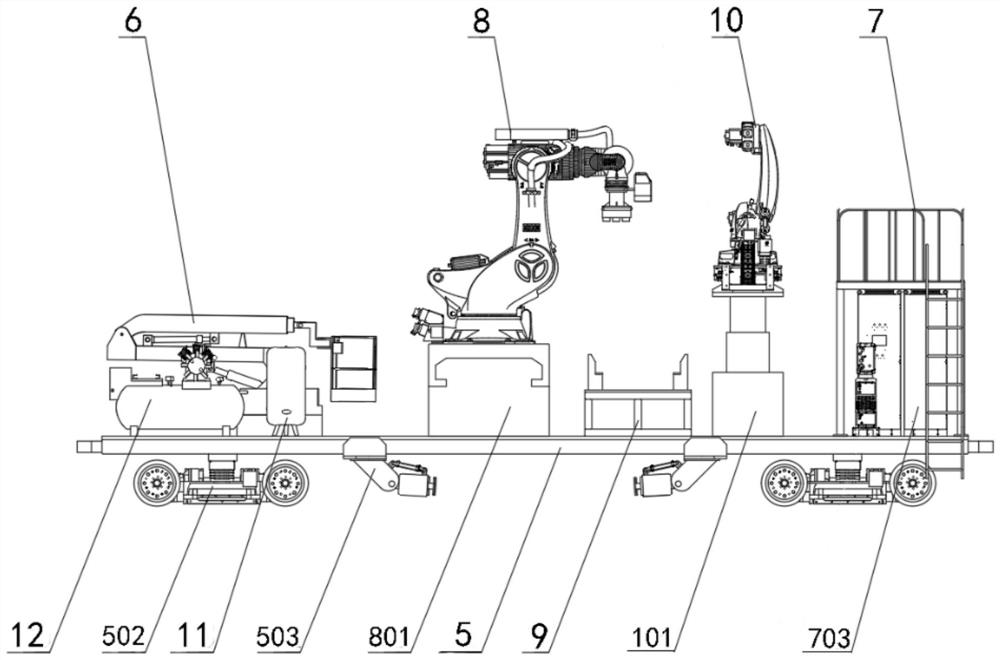

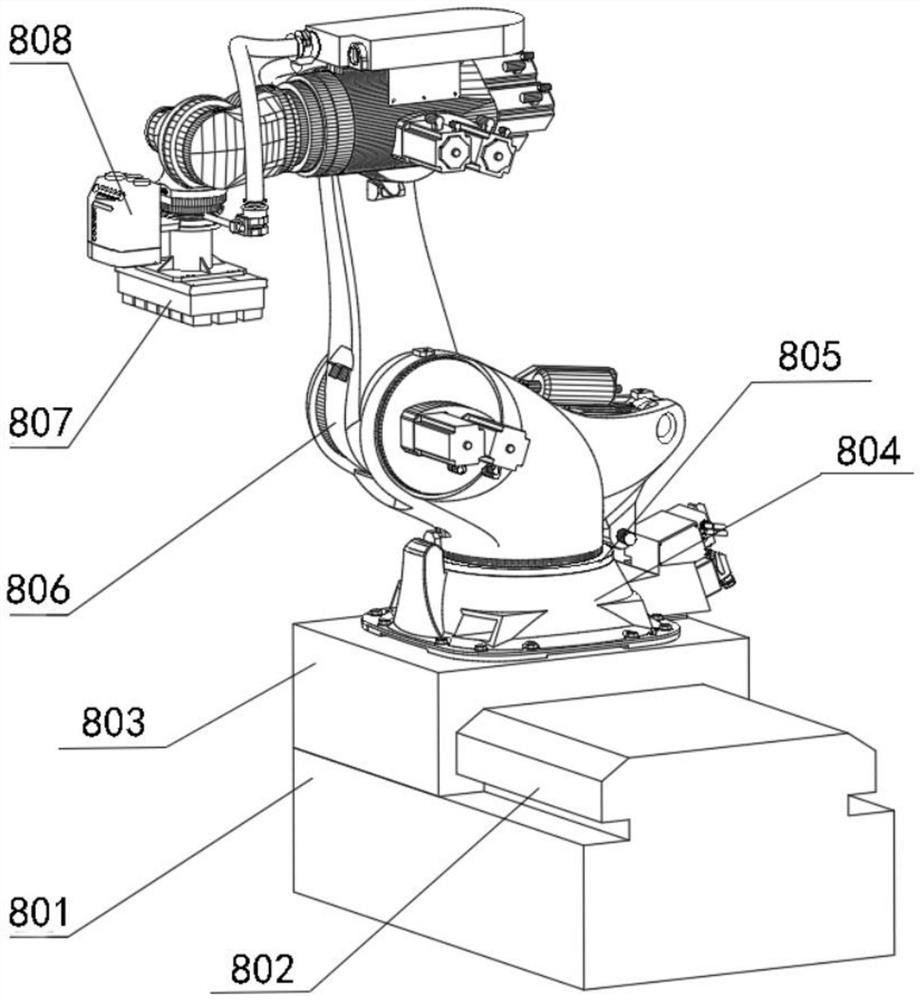

[0043] A complete set of equipment for the repair and reinforcement of shield subway tunnel segments, including a bottom system 1, an assembly robot system 2, a welding robot system 3 and an auxiliary operation platform system 4, the bottom system 1 includes a two-way traction flatbed vehicle 5, and the auxiliary operation platform The system 4 includes the crank arm type manual work platform 6 and the fixed manual work platform 7 arranged on the two-way traction flat car 5, and the assembly robot system 2 includes the assembly mechanical arm 8 and the steel plate ring arranged on the two-way traction flat car 5 The storage rack 9, the welding robot system 3 includes a welding robot arm 10 arranged on a two-way traction flatbed vehicle 5.

[0044] The assembly mechanical arm 8, the steel plate ring storage rack 9, the crank arm type manual operation platform 6 and the fixed manual operation platform 7 are arranged on the two-way traction flatbed truck 5, wherein the assembly me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com