Lithium-supplementing negative electrode and application thereof

A technology for supplementing lithium and negative electrodes, which is applied to negative electrodes, battery electrodes, active material electrodes, etc., and can solve the problems of lithium precipitation risk, limited improvement in first-time charge-discharge efficiency and cycle performance of lithium-ion batteries, and low lithium supplementation efficiency. , to achieve the effect of improving cycle performance, inhibiting lithium dendrite phenomenon, and ensuring safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

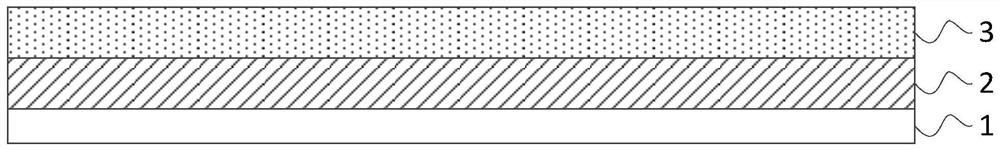

Image

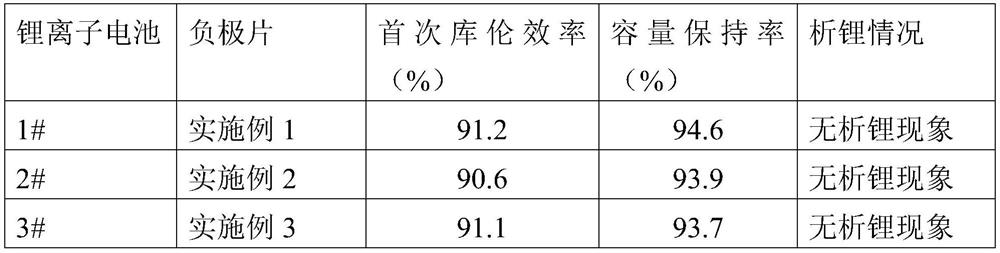

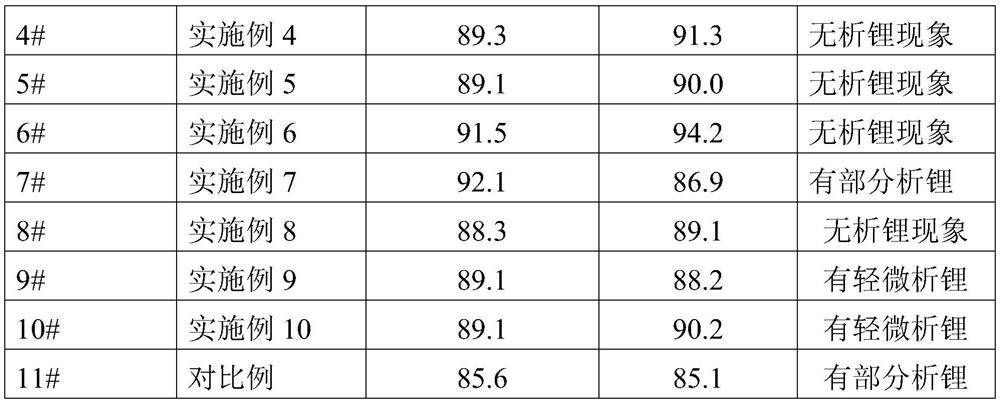

Examples

Embodiment 1

[0056] The preparation method of the present embodiment lithium replenishment negative electrode comprises:

[0057] 1. Lithium supplement slurry

[0058] In an environment with a humidity of 7 La 3 Zr 2 o 12 , electronic conductive agent SP, Al 2 o 3 , binder PTFE and inert lithium powder are dissolved in NMP solution to form a solid content of 38.2wt% and a viscosity of 2400mPa. s lithium supplement slurry;

[0059] The solid (non-NMP solution) in the lithium-supplementing slurry includes: lithium ion conductive agent LLZO 35wt%, conductive agent SP 2.0wt%, Al 2 o 3 20wt%, binder PTFE 3% and inert lithium powder 40%.

[0060] 2. Negative electrode active slurry

[0061] Mix the silicon-oxygen negative electrode with graphite to make a negative electrode material with a specific capacity of 500mAh / g (named SiO-500). After mixing SiO-500, conductive agent SP, and binder at a mass ratio of 92:4:4, Add appropriate amount of NMP to obtain negative electrode active slur...

Embodiment 2

[0068] The preparation method of the present embodiment lithium replenishment negative electrode comprises:

[0069] 1. Lithium supplement slurry

[0070] In an environment with a humidity of 1.5 al 0.5 Ge 1.5 (PO 4 ) 3 (LATP), electronic conductive agent CNT, SiO 2 , binder PVDF and inert lithium powder are dissolved in NMP solution to form a solid content of 45.2wt% and a viscosity of 2400mPa. s lithium supplement slurry;

[0071] The solids in the lithium-supplementing slurry include: lithium ion conductive agent LATP 40%, conductive agent CNT0.5%, SiO 2 21.5%, binder PVDF 3% and inert lithium powder 35%.

[0072] 2. Negative electrode active slurry

[0073] Same as embodiment 1;

[0074] 3. Lithium supplement negative electrode

[0075] Coat the negative electrode active slurry on the upper surface of the Cu foil and dry and roll to form the negative electrode active layer, wherein the surface density of the negative electrode active layer is 8.0mg / cm 2 , the co...

Embodiment 3

[0079] The preparation method of the present embodiment lithium replenishment negative electrode comprises:

[0080] 1. Lithium supplement slurry

[0081] In an environment with a humidity of 1.5 al 0.5 Ge 1.5 (PO 4 ) 3 (LAGP), electronic conductive agent SP, boehmite, binder PTFE and inert lithium powder are dissolved in NMP solution to form a solid content of 32wt% and a viscosity of 1900mPa. s lithium supplement slurry;

[0082] The solids in the lithium-supplementing slurry include: 25wt% of lithium ion conductive agent LAGP, 0.5wt% of conductive agent SP, 22.5wt% of boehmite, 2% of binder PTFE and 50wt% of inert lithium powder.

[0083] 2. Negative electrode active slurry

[0084] Same as embodiment 1;

[0085] 3. Lithium supplement negative electrode

[0086] Coat the negative electrode active slurry on the upper surface of Cu foil and dry and roll to form the negative electrode active layer, wherein the surface density of the negative electrode active layer is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com