Full recycling method of red mud

A full recovery and red mud technology, applied in the field of solid waste recycling, can solve the problems of large storage capacity of alumina red mud, difficult processing, environmental pollution, etc., and achieve no secondary pollution, low cost, and economic benefits. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

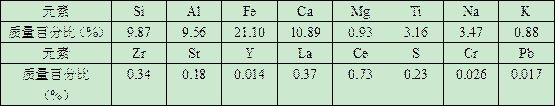

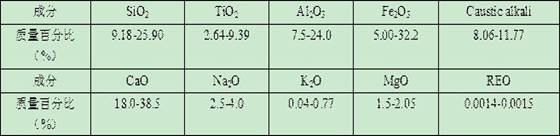

[0048] In this example, the alumina red mud provided by the Xiaoyanghe red mud warehouse of Sanmenxia City, Henan Province Dongfang Hope Aluminum Co., Ltd. is used as the processing raw material. The specific treatment process of the alumina red mud is as follows:

[0049] (1) Take 1 kg of alumina red mud (sourced from the Xiaoyang River red mud reservoir of Sanmenxia Dongfang Hope Aluminum Co., Ltd.), add 400mL of tap water to it and stir to make a slurry, and then, under constant stirring conditions, start to drip When adding concentrated sulfuric acid solution, a large amount of foam will be generated at the beginning and the temperature will rise. With the continuous addition of concentrated sulfuric acid and rapid stirring, the foam will gradually disappear. Stop adding acid when no foam is generated. At this time, the amount of concentrated sulfuric acid added is 108mL (about 200 grams), continue to stir and react for 10-15 minutes, filter with a belt vacuum filter, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com