Method for removing fluorine and chlorine in zinc smelting electrolyte

A zinc electrolyte and electrolyte technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as complex composition, large amount of sedimentation residue, and large amount of residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The composition of the zinc electrolyte is as follows:

[0067] Zinc ion concentration is 80g / L, fluoride ion concentration is 1000mg / L, chloride ion concentration is 2500mg / L; pH value is 7.0.

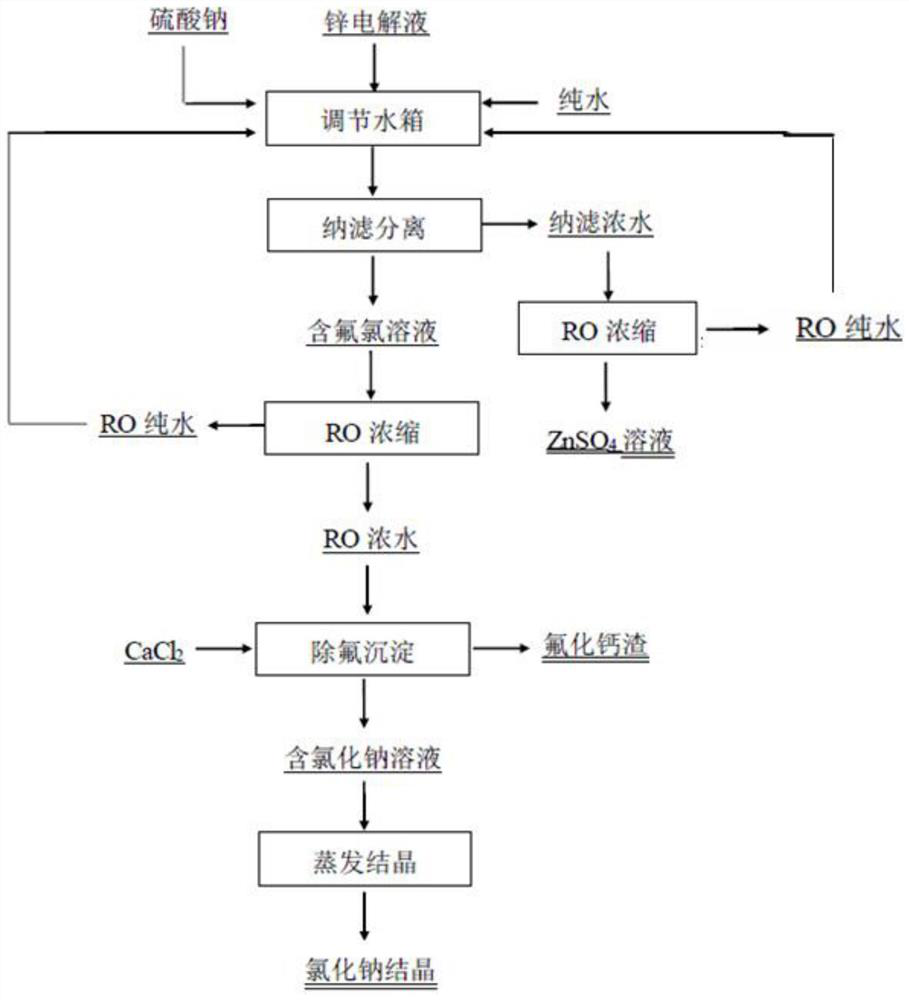

[0068] For processing see figure 1 , figure 1 It is a schematic flow diagram of removing fluorine and chlorine from the zinc smelting electrolyte in an embodiment of the present invention, specifically including:

[0069] S1. Take 100L of zinc electrolyte, 500L of pure water, and 1.75kg of sodium sulfate and add them to the regulating water tank, and control the ratio of the moles of sodium ions in the regulating water tank to the total moles of fluorine and chloride ions to be 1:1. Adjust the mixed liquid in the water tank to enter the nanofiltration system for nanofiltration separation.

[0070] The operating conditions of nanofiltration separation are: pressure 6.0MPa, temperature 12°C, membrane surface flow velocity 0.041m / s, pH 5.3.

[0071] After separation by nanofil...

Embodiment 2

[0083] The composition of the zinc electrolyte is as follows:

[0084] Zinc ion concentration is 80g / L, fluoride ion concentration is 1000mg / L, chloride ion concentration is 2500mg / L; pH value is 7.0.

[0085] The process is as follows:

[0086] S1. Take 100L of zinc electrolyte, 200L of pure water, and 1.75kg of sodium sulfate and add them to the regulating water tank, and control the ratio of the moles of sodium ions in the regulating water tank to the total moles of fluorine and chloride ions to be 1:1. Adjust the mixed liquid in the water tank to enter the nanofiltration system for nanofiltration separation.

[0087] The operating conditions of nanofiltration separation are: pressure 4.2MPa, temperature 16°C, membrane surface flow velocity 0.035m / s, pH 4.8.

[0088] After separation by nanofiltration, 90L nanofiltration concentrated water (zinc concentration is 1.37mol / L) and 210L fluorine-containing chlorine solution (sulfate radical concentration is 200mg / L) are obtained...

Embodiment 3

[0100] The composition of the zinc electrolyte is as follows:

[0101] Zinc ion concentration is 160g / L, fluoride ion concentration is 1000mg / L, chloride ion concentration is 2500mg / L; pH value is 7.0.

[0102] The process is as follows:

[0103] S1. Take 100L of zinc electrolyte, 500L of pure water, and 2.62kg of sodium sulfate and add them to the regulating water tank, and control the ratio of the moles of sodium ions in the regulating water tank to the total moles of fluorine and chloride ions to be 1.5:1. Adjust the mixed liquid in the water tank to enter the nanofiltration system for nanofiltration separation.

[0104] The operating conditions of nanofiltration separation are: pressure 7.5MPa, temperature 22°C, membrane surface flow velocity 0.045m / s, pH 5.1.

[0105] After separation by nanofiltration, 110L of nanofiltration concentrated water (with a zinc concentration of 2.24mol / L) and 490L of fluorine-containing chlorine solution (with a sulfate radical concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com