Treatment method of lead-zinc smelting waste acid

A treatment method and technology for polluted acid, applied in non-polluting water treatment, metallurgical wastewater treatment, water/sewage treatment, etc., can solve the problems of high treatment cost, high energy recovery cost, complicated equipment composition, etc., and achieve high-efficiency separation, The effect of easy access and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The components of dirty acid are as follows:

[0071] The zinc concentration is 100mg / L, the lead concentration is 10mg / L, the arsenic concentration is 40mg / L, the cadmium concentration is 100mg / L, the sulfuric acid concentration is 30g / L, the chlorine concentration is 1g / L, and the fluorine concentration is 2g / L.

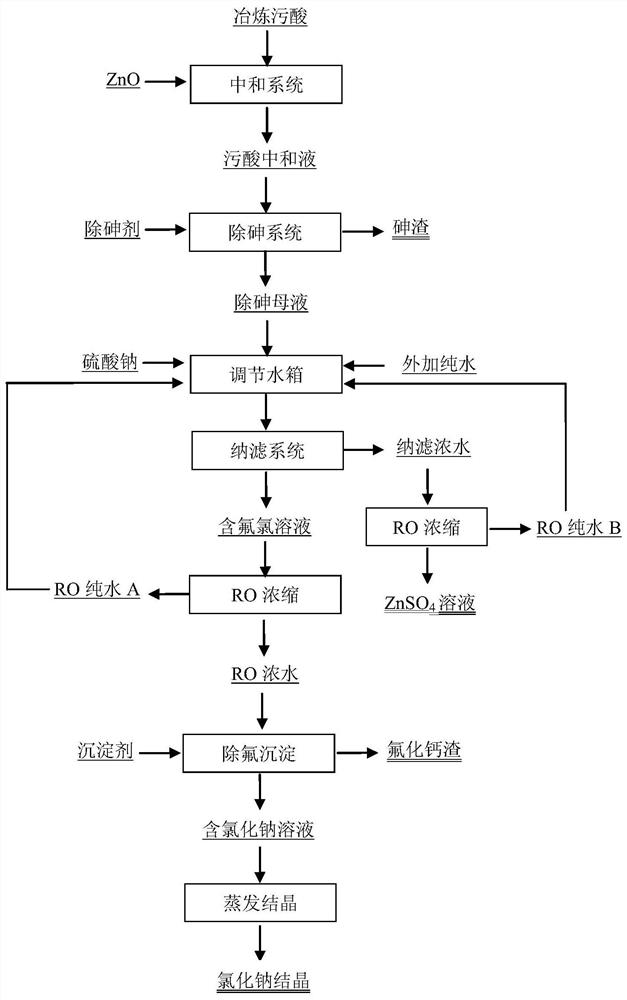

[0072] For processing see figure 1 , figure 1 It is a schematic flow diagram of processing smelting sewage acid according to the embodiment of the present invention, specifically including:

[0073] S1. Add 1.25 kg of ZnO to 50 L of polluted acid, control the reaction pH to 5.0, and stir for 1 hour to obtain a neutralizing solution of polluted acid.

[0074] S2, add 10g Fe to 50L dirty acid neutralizing solution 2 (SO 4 ) 3 , control the reaction pH to 4.0, stir the reaction for 1 hour, and obtain the arsenic slag and arsenic removal mother liquor after filtration.

[0075] S3. Add 50L of arsenic-removing mother liquor, 100L of pure water, and 0.95kg o...

Embodiment 2

[0089] The components of dirty acid are as follows:

[0090] The zinc concentration is 300mg / L, the lead concentration is 13mg / L, the arsenic concentration is 80mg / L, the cadmium concentration is 50mg / L, the sulfuric acid concentration is 200g / L, the chlorine concentration is 3g / L, and the fluorine concentration is 0.5g / L.

[0091] For processing see figure 1 , figure 1 It is a schematic flow diagram of processing smelting sewage acid according to the embodiment of the present invention, specifically including:

[0092] S1. Add 8.30 kg of ZnO to 50 L of polluted acid, control the reaction pH to 6.5, and stir for 1 hour to obtain a neutralizing solution of polluted acid.

[0093] S2, add 18g Fe in 50L polluted acid neutralization liquid 2 (SO 4 ) 3 , control the reaction pH to 6.0, stir the reaction for 1 hour, and obtain the arsenic slag and arsenic removal mother liquor after filtration.

[0094] S3. Add 50L of arsenic-removing mother liquor, 250L of pure water, and 1.1...

Embodiment 3

[0108] The components of dirty acid are as follows:

[0109] The zinc concentration is 150mg / L, the lead concentration is 18mg / L, the arsenic concentration is 100mg / L, the cadmium concentration is 80mg / L, the sulfuric acid concentration is 90g / L, the chlorine concentration is 0.5g / L, and the fluorine concentration is 3g / L.

[0110] S1. Add 3.72 kg of ZnO to 50 L of polluted acid, control the reaction pH to 7.0, and stir for 1 hour to obtain a neutralizing solution of polluted acid.

[0111] S2, add 20g Fe to 50L dirty acid neutralizing solution 2 (SO 4 ) 3 , control the reaction pH to 5.0, stir the reaction for 1 hour, and obtain the arsenic slag and arsenic removal mother liquor after filtration.

[0112] S3. Add 50L of arsenic-removing mother liquor, 100L of pure water, and 1.47kg of sodium sulfate into the regulating water tank, and control the ratio of the moles of sodium ions in the regulating water tank to the total moles of fluorine and chloride ions to be 1.2:1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com