Preparation method of crystal form B avibactam sodium

A technology of avibactam sodium and crystal form, which is applied in the field of preparation of crystal form B avibactam sodium, and can solve the problems of difficult industrialized and stable production of crystal form B avibactam sodium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

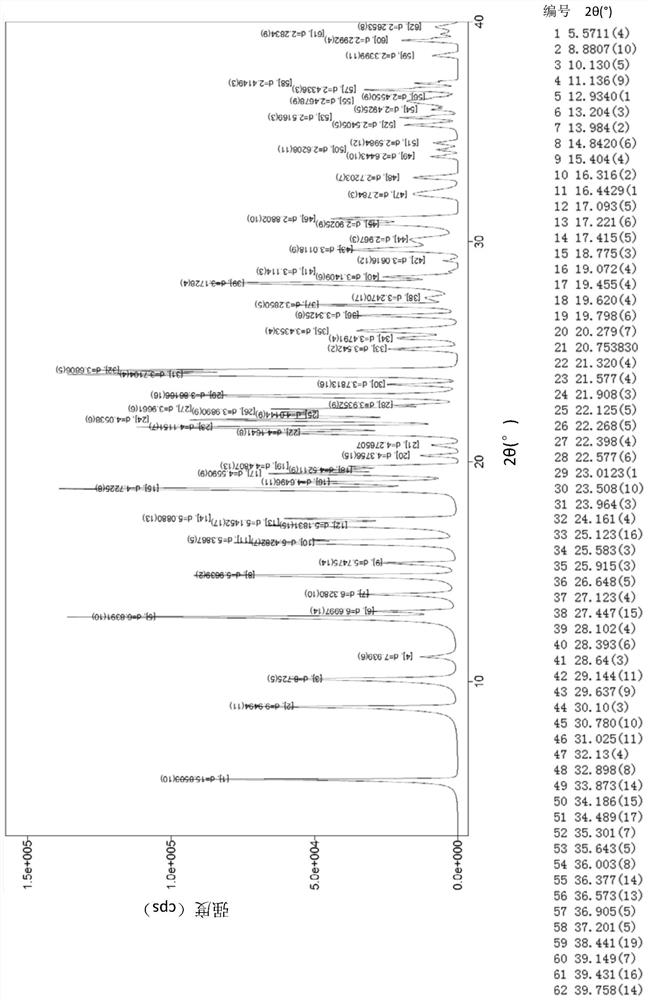

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention provides a preparation method of crystal form B avibactam sodium, comprising:

[0039] S100, adding methanol and water to the avibactam sodium, then stirring and heating to dissolve to obtain the avibactam sodium solution;

[0040] S200, adding an alcoholic poor solvent into the avibactam sodium solution, cooling to a first temperature, stirring and growing crystals, and then continuing cooling to a second temperature for crystallization.

[0041] The present invention stably prepares crystal form B avibactam sodium by means of crystallization, by adding methanol and water to avibactam sodium, and heating and dissolving to make avibactam sodium of various crystal forms (including amorphous) Transform into a uniform avibactam sodium solution, then add alcohol poor solvents for two-step cooling, first cool down for crystal growth, so that various crystal forms of avibactam sodium can be converted to type B, and then continue to cool...

Embodiment 1

[0062] Step (1): Add 50 mL of methanol and 6 mL of water to 10 g of avibactam sodium in crystal form D in sequence, stir and heat up to 55-60°C to dissolve;

[0063] Step (2): Add 600mL of ethanol dropwise at a stirring speed of 200rpm (, after the dropwise addition is completed, cool down to 30-35°C, continue to grow crystals at a stirring speed of 200rpm for 16h, then cool down to -5-5°C and stir for 2h, filter with suction , washed with 20 mL of ethanol, and dried in vacuum for 14 hours to obtain 8.5 g of avibactam sodium (yield 85%).

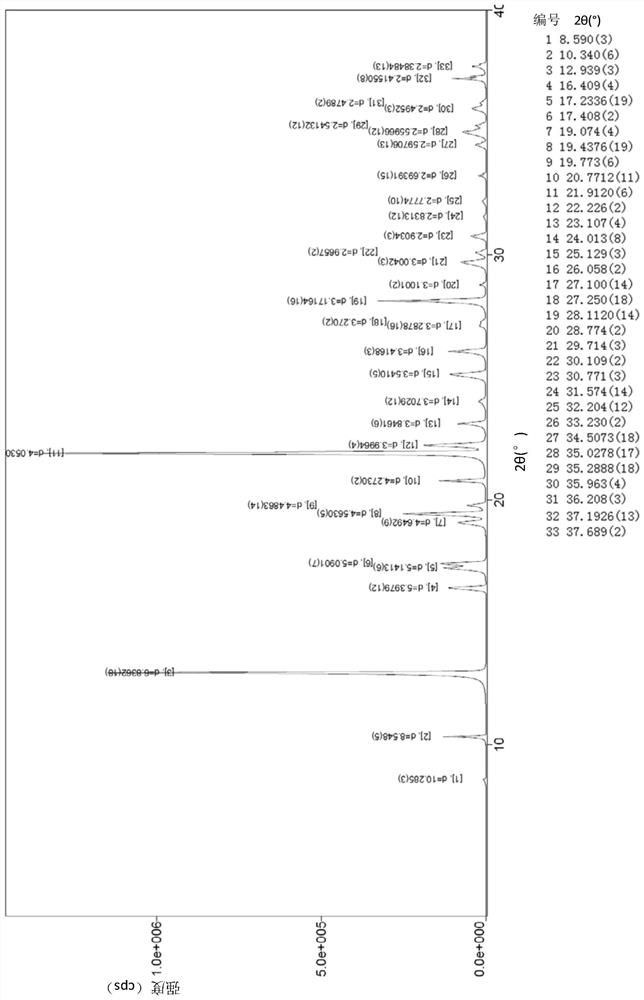

[0064] The obtained avibactam sodium sample is analyzed by XRD as anhydrous "B" crystal form avibactam sodium, and the XRD figure is as follows figure 2 shown.

Embodiment 2

[0066] Step (1): Add a mixed solvent of 70 mL of methanol and 5.7 mL of water to 10 g of avibactam sodium in crystal form A, stir and heat up to 60-65°C to dissolve;

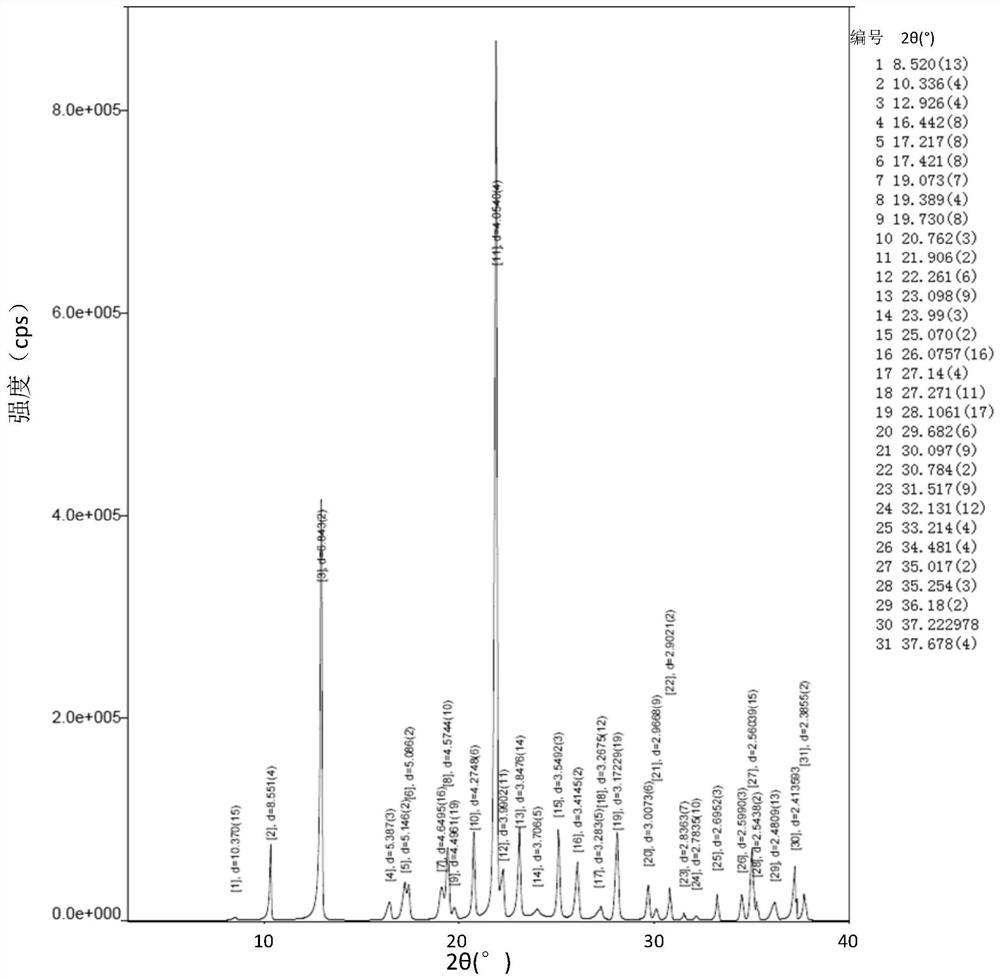

[0067] Step (2): Add 530mL of isopropanol dropwise at a stirring speed of 250rpm (, after the dropwise addition is completed, cool down to 25-30°C, continue to grow crystals at a stirring speed of 250rpm for 16h, then cool down to 15-20°C and stir for 1h, pump Filtered, washed with 20 mL of ethanol, and dried in vacuum for 16 hours to obtain 8.0 g of avibactam sodium (yield 80%).

[0068] The obtained avibactam sodium sample is analyzed by XRD as anhydrous "B" crystal form avibactam sodium, and the XRD figure is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com