Method for preparing periodic microstructure on surface of titanium alloy through nanosecond laser irradiation

A laser irradiation and titanium alloy technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult periodic structure, uncontrollable partial flow of melt, and evaporation phenomenon, achieving good repeatability, The effect of low processing cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The following titanium alloys are preferably Ti6Al4V, which is one of the most widely used titanium alloys and is used in machinery, aerospace, biomedical and other fields, but other types of titanium alloys can also be used.

[0036] (1) Wire-cut the Ti6Al4V raw material into a square sample of 20mm×20mm×3mm, mechanically grind and polish the Ti6Al4V sample, and use absolute ethanol to perform ultrasonic cleaning for 5min. The cleaning temperature of ultrasonic cleaning is 50°C. Let dry naturally.

[0037] (2) Place the treated Ti6Al4V sample in the gas chamber, open the gas valve, and feed high-purity nitrogen gas at a gas flow rate of 5L / min. The laser beam is irradiated vertically on the surface of the titanium alloy sample through the silica glass.

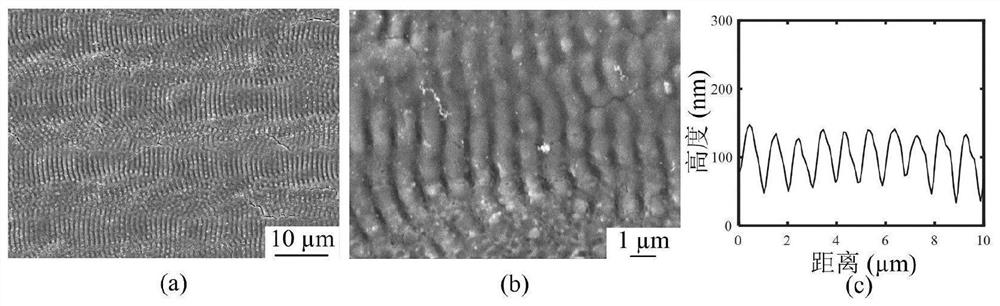

[0038](3) Adjust the parameters of the nanosecond laser, set the laser power to 4.46W through the control software, the laser scanning speed to 10mm / s, the laser repetition frequency to 700kHz, the laser pulse width t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com