Decorative veneering sheet and preparation method thereof

A veneer and film technology, applied in chemical instruments and methods, lamination devices, flat products, etc., can solve the problems of poor weather resistance of PETG, limited scope of action, and inability to achieve long-term outdoor use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

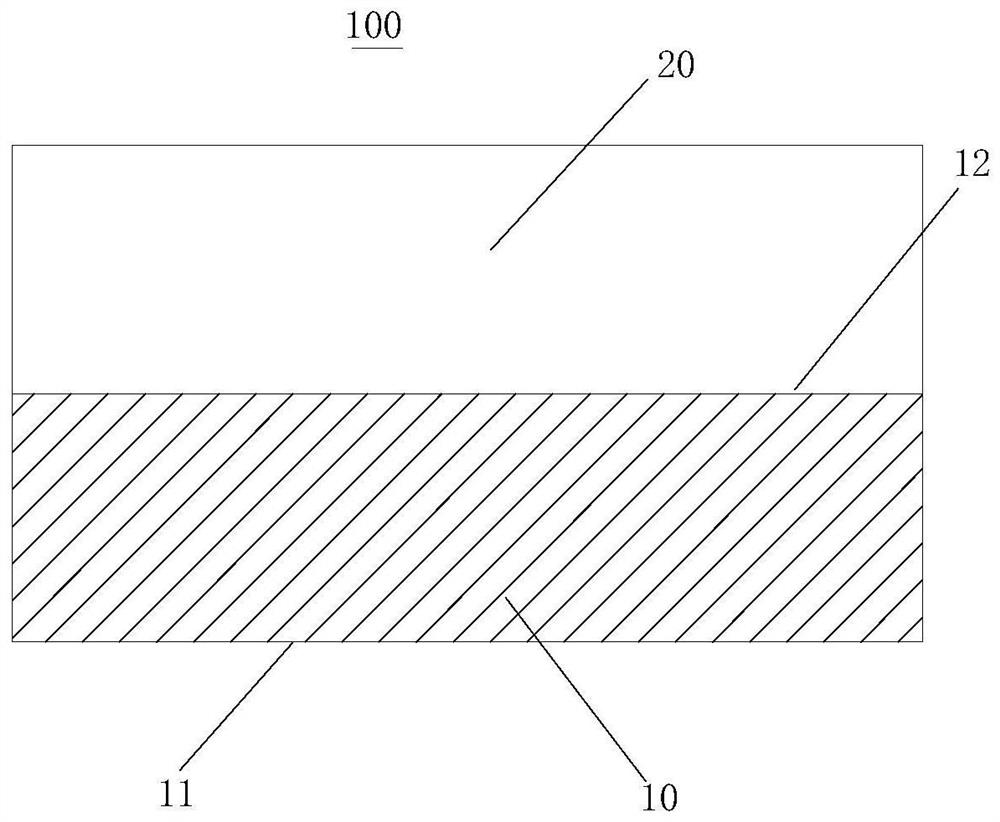

[0030] A decorative veneer sheet 100 and its preparation method according to the first aspect of the present invention, comprising:

[0031] PETG resin diaphragm 10 has opposite inner end face 11 and outer end face 12;

[0032] The ASA resin film 20 is pasted on the outer end surface 12 of the PETG resin film 10 .

[0033] In this technical solution, by covering the surface of the PETG resin film 10 with a layer of ASA resin film 20, the anti-ultraviolet performance is obviously improved, and the transparency is good, the weather resistance is strong, and the mechanical properties are superior; at the same time, the cost is reduced.

[0034] In an example of the present invention, the PETG resin film 10 and the ASA resin film 20 are formed by a co-extrusion process.

[0035] In an example of the present invention, the components of the ASA resin film 20 and the content of each component by weight are as follows: resin 94-98wt%, toner 0-5wt%, antioxidant 0.1-0.5wt%, 0.1-0.5 w...

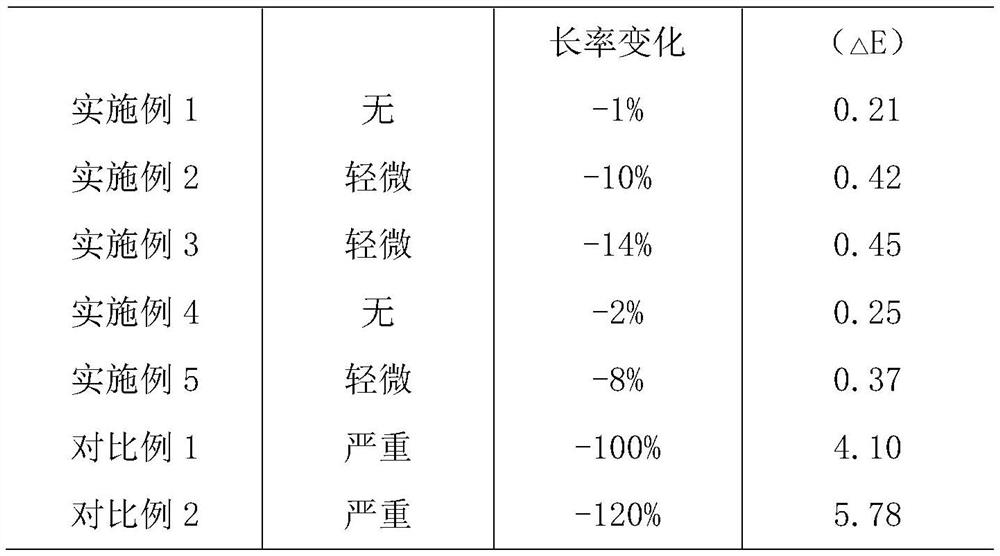

Embodiment 1

[0049] ASA resin diaphragm 20 components and each component content are as follows: by weight, ASA (LI970) resin 93wt%, toner 5wt%, antioxidant 0.5wt%, ultraviolet absorber (Tinuvin 234) 0.5wt%, increase Sticky chain extender JW-AG 1wt%.

[0050] The 10 components of the PETG resin film and the contents of each component are as follows: PETG (S2008) resin 94%, toner 5wt%, antioxidant 0.5wt%, ultraviolet absorber (Tinuvin 234) 0.5wt%, rheology control agent RC -620 0.5 wt%.

[0051] The extrusion molding process of ASA / PETG co-extruded film is carried out as follows:

[0052] 1) After the ASA resin is dried, it is fully mixed with toner, antioxidant, ultraviolet absorber, and viscosity-increasing chain extender through a high-speed mixer to obtain an ASA compound, which is added to an extruder to melt and plasticize;

[0053] 2) After the PETG resin is dried, it is fully mixed with toner, antioxidant, ultraviolet absorber, and rheology regulator through high-speed mixing to o...

Embodiment 2

[0057] ASA resin diaphragm 20 components and each component content are as follows: by weight, ASA (LI970) resin 98wt%, antioxidant 0.5wt%, ultraviolet absorber (Tinuvin 234) 0.5wt%, tackifying chain extender 0.5 wt%.

[0058] The 10 components of the PETG resin film and the contents of each component are as follows: PETG (S2008) resin 98%, antioxidant 0.5wt%, ultraviolet absorber (Tinuvin 234) 0.5wt%, rheology control agent RC-620 0.5wt% .

[0059] The extrusion molding process of ASA / PETG co-extruded film is carried out as follows:

[0060] 1) After the ASA resin is dried, it is fully mixed with an antioxidant, an ultraviolet absorber, and a viscosity-increasing chain extender through a high-speed mixer to obtain an ASA compound, which is added to an extruder to melt and plasticize;

[0061] 2) After the PETG resin is dried, it is fully mixed with an antioxidant, an ultraviolet absorber, and a rheology regulator through high-speed mixing to obtain a PETG compound, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com