Optical dielectric ferroelectric ceramic material as well as preparation method and application thereof

A technology of ferroelectric ceramics and ceramic raw materials, applied in the field of ceramic materials, can solve the problems of low dielectric tunability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The present invention also provides a preparation method for the optical dielectric ferroelectric ceramic material described in the above technical solution, comprising the following steps:

[0085] According to the stoichiometric ratio of the general chemical formula of the optical dielectric ferroelectric ceramic material, the K source, the Na source, the Nb source, the A source and the M source are mixed and ball milled to obtain a ceramic raw material mixed powder;

[0086] The ceramic raw material mixed powder is sequentially granulated, pressed and sintered to obtain the photoelectric ferroelectric ceramic material.

[0087] The invention mixes K source, Na source, Nb source, A source and M source according to the stoichiometric ratio of the general chemical formula of the optical dielectric ferroelectric ceramic material, and then performs ball milling to obtain ceramic raw material mixed powder.

[0088] In the present invention, the purity of the K source, Na s...

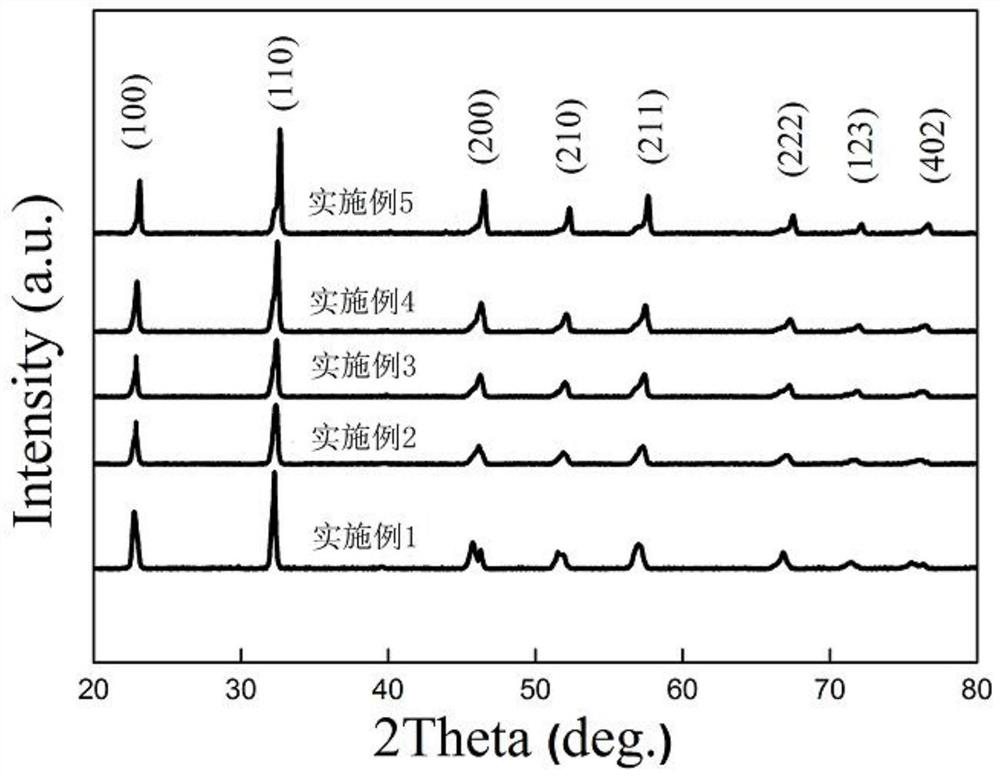

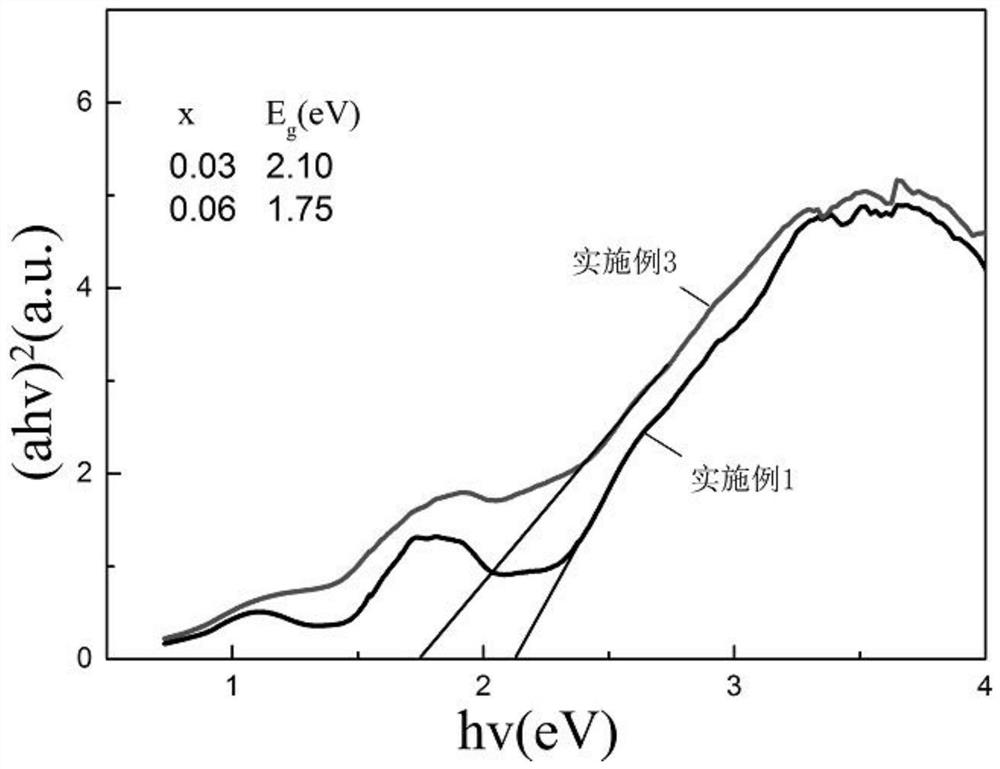

Embodiment 1

[0104] In this embodiment, the preparation raw materials are all commercially available, and the purity is more than or equal to 99%; the chemical general formula of the designed optical dielectric ferroelectric ceramic material is 0.97 (K 0.5 Na 0.5 )NbO 3 -0.03Ca(Ni 0.5 Nb 0.5 )O 3-δ ;

[0105] Preparation:

[0106] According to the stoichiometric ratio of elements in the general chemical formula of photoelectric ferroelectric ceramic materials, 2.5753g of Na 2 CO 3 , 0.3033g of CaCO 3 , 3.3683g of K 2 CO 3 , 0.1132g of NiO 2 and 13.1304g of Nb 2 o 5 Mix and place in a drum-type ball mill, use zirconium balls with a diameter of 3.8mm and 7.6mm as the grinding balls (the number ratio of zirconium balls with a diameter of 3.8mm and 7.6mm is 2:1), add 80mL of absolute ethanol as a liquid Medium, the first ball milling was carried out at 400rpm for 18h, the obtained ball milling colander was separated, dried in an oven at 70°C for 3h, passed through a 100-mesh sieve...

Embodiment 2

[0111] The general chemical formula of the optical dielectric ferroelectric ceramic material is designed to be 0.955 (K 0.5 Na 0.5 )NbO 3 -0.045Ca(Ni 0.5 Nb 0.5 )O 3-δ ;

[0112] According to the stoichiometric ratio of elements in the general chemical formula of photoelectric ferroelectric ceramic materials, Na 2 CO 3 , CaCO 3 、K 2 CO 3 , NiO 2 and Nb 2 o 5 In order to prepare the material, the rest of the technical means are the same as in Example 1 to obtain the optical dielectric ferroelectric ceramic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com