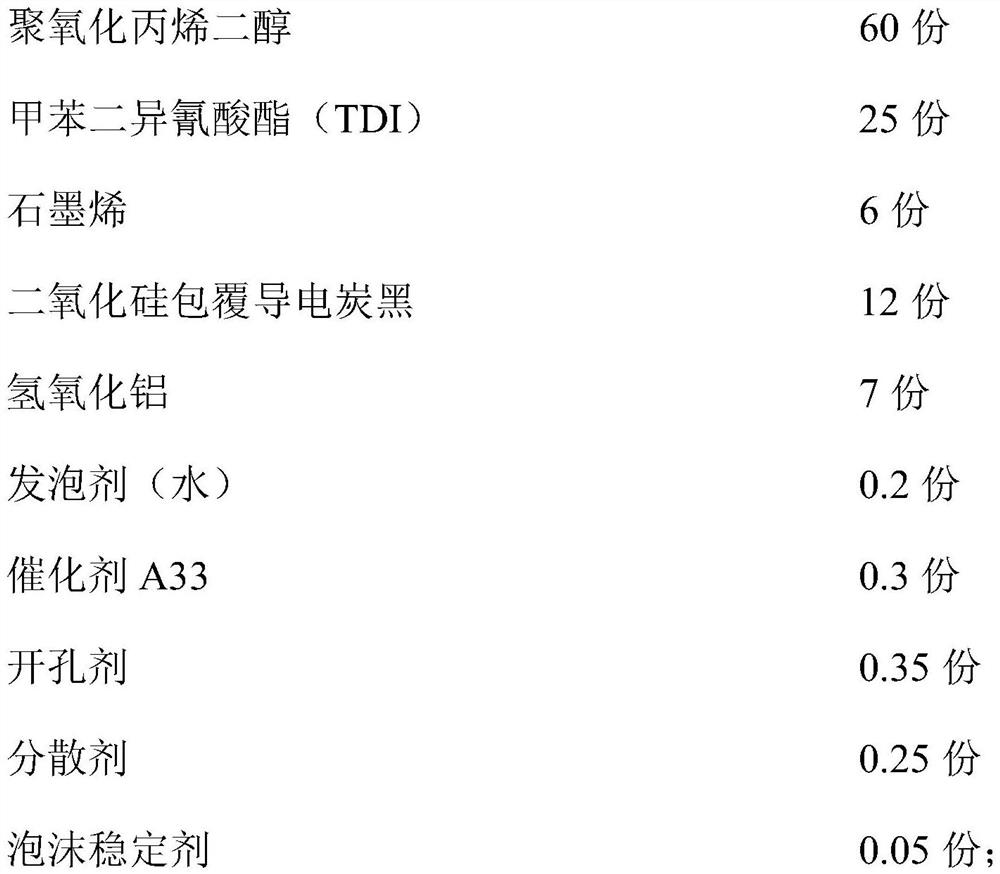

Flame-retardant graphene polyurethane composite sponge material and application

A technology of composite sponge and graphene, applied in the field of sponge materials, can solve the problems such as inability to exert graphene performance, large combustion heat release, low electrical conductivity, etc., and achieve high elasticity, good strength, and excellent flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

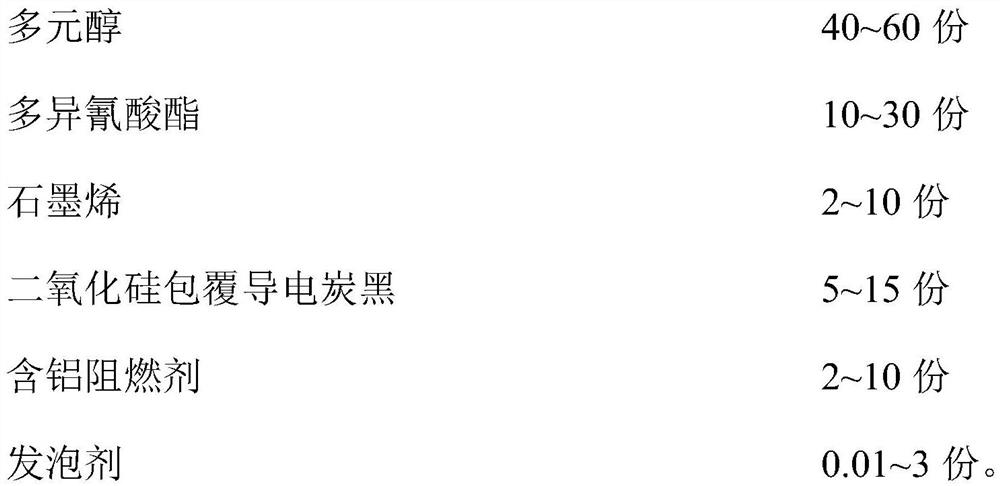

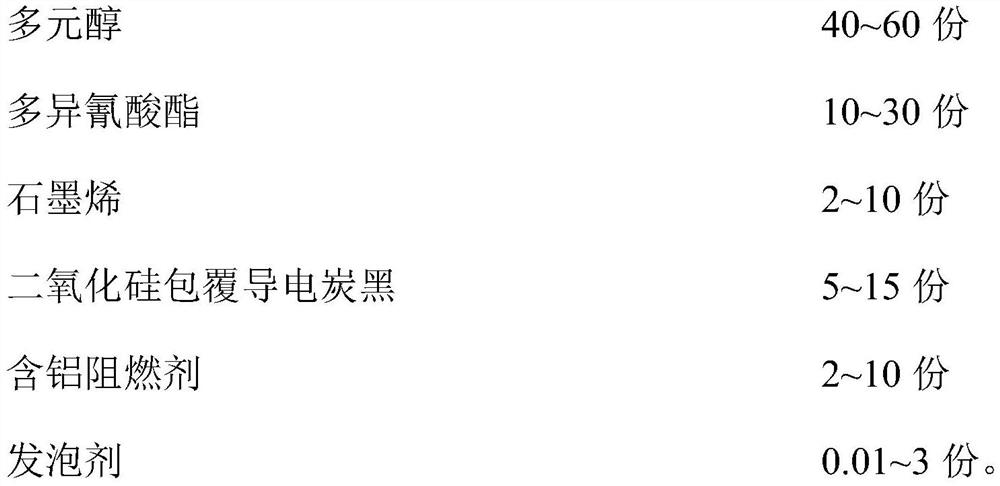

[0069] A flame-retardant graphene polyurethane composite sponge material, the preparation raw materials include the following components in parts by weight:

[0070]

[0071] The preparation method is as follows:

[0072] (1) Add polyoxypropylene glycol, graphene, silicon dioxide-coated conductive carbon black, aluminum hydroxide and dispersant to the reaction kettle, stir and mix evenly under heating conditions, and then the material is used in a three-stage container with a diameter of 260mm The roller machine is used for circular dispersion until the fineness is less than 20 μm to obtain polyol slurry;

[0073] (2) Add foaming agent, catalyst, cell opener and foam stabilizer to the polyol slurry obtained in step (1), and mix uniformly to obtain component A;

[0074] (3) Maintain the component A and TDI obtained in step (2) at a temperature of 45°C, pump them into a dynamic mixer with a mass ratio of 4:1 and mix them evenly, and then send them into a continuous foaming p...

Embodiment 2

[0076] A flame-retardant graphene polyurethane composite sponge material, the preparation raw materials include the following components in parts by weight:

[0077]

[0078] The preparation method is as follows:

[0079] (1) Add polytetrahydrofuran diol, graphene, silicon dioxide-coated conductive carbon black, aluminum hydroxide, magnesium hydroxide and a dispersant into the reactor, stir and mix evenly under heating conditions, and then use a material with a diameter of A 260mm three-roll machine is used for circular dispersion until the fineness is less than 20μm to obtain polyol slurry;

[0080] (2) Add foaming agent, catalyst, cell opener and foam stabilizer to the polyol slurry obtained in step (1), and mix uniformly to obtain component A;

[0081] (3) Maintain component A and 4,4'-MDI obtained in step (2) at a temperature of 50°C, pump them into a dynamic mixer at a mass ratio of 3:1 and mix them evenly, and then send them to a continuous foaming production line ,...

Embodiment 3

[0083] A flame-retardant graphene polyurethane composite sponge material, the preparation raw materials include the following components in parts by weight:

[0084]

[0085] The preparation method is as follows:

[0086] (1) Add polyoxypropylene glycol, propylene glycol, graphene, silica-coated conductive carbon black, aluminum hypophosphite and dispersant into the reaction kettle, stir and mix evenly under heating conditions, and then use a material with a diameter of 260mm The three-roll machine is used for circular dispersion until the fineness is less than 20 μm, and polyol slurry is obtained;

[0087] (2) Add foaming agent, catalyst, cell opener and foam stabilizer to the polyol slurry obtained in step (1), and mix uniformly to obtain component A;

[0088] (3) Maintain the component A and TDI obtained in step (2) at a temperature of 50°C, pump them into a dynamic mixer with a mass ratio of 5:1 and mix them evenly, and then send them into a continuous foaming producti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Indentation hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com