High-temperature ebonite recyclable foam drilling fluid and preparation method thereof

A drilling fluid and high-temperature technology, which is applied in the field of foam drilling fluid and its preparation, can solve the problems of insufficient service life of recyclable foam drilling fluid, short foam half-life, high bentonite content, etc., achieve strong resistance to metal ion pollution, and improve application accuracy , The effect of simplifying the preparation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the aforementioned high-temperature hard glue recyclable foam drilling fluid includes:

[0059] (1) Take 100 parts of clear water, add 0.2-0.8 parts of low-molecular-weight anti-high-temperature foam stabilizer to it, and stir with a low-speed mixer for 1-4 hours; after uniform dispersion and dissolution, add 0.1-0.2 parts of high-temperature wetting agent, and fully stir for 10-4 hours 30 minutes; add 1 to 2 parts of bubble film density reducer, fully stir for 5 to 10 minutes, and let it stand for 2 to 4 hours to ensure that it is fully swollen to form a temperature-resistant and hard gum base liquid;

[0060] (2) Weigh 0-3 parts of temperature-resistant sodium bentonite, 0-0.1 parts of alkaline regulator, 0.1-0.5 parts of high-temperature polymer fluid loss reducer, 0.3-0.5 parts of high-temperature foaming agent, and high-temperature and salt-resistant fluid loss reducer Mix 1-3 parts of the lost agent evenly, add it into the temperature-res...

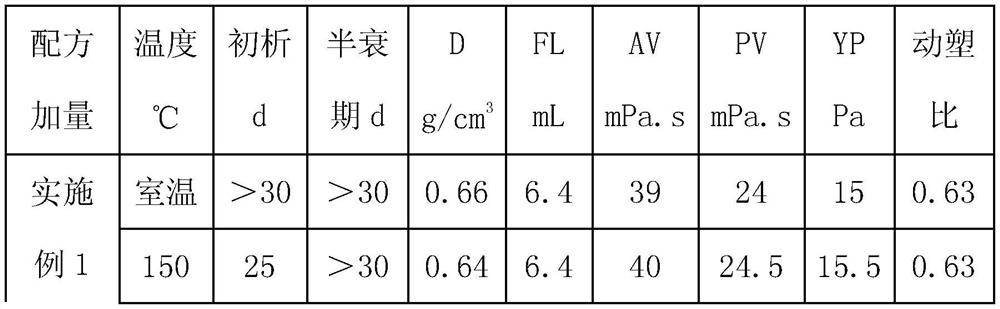

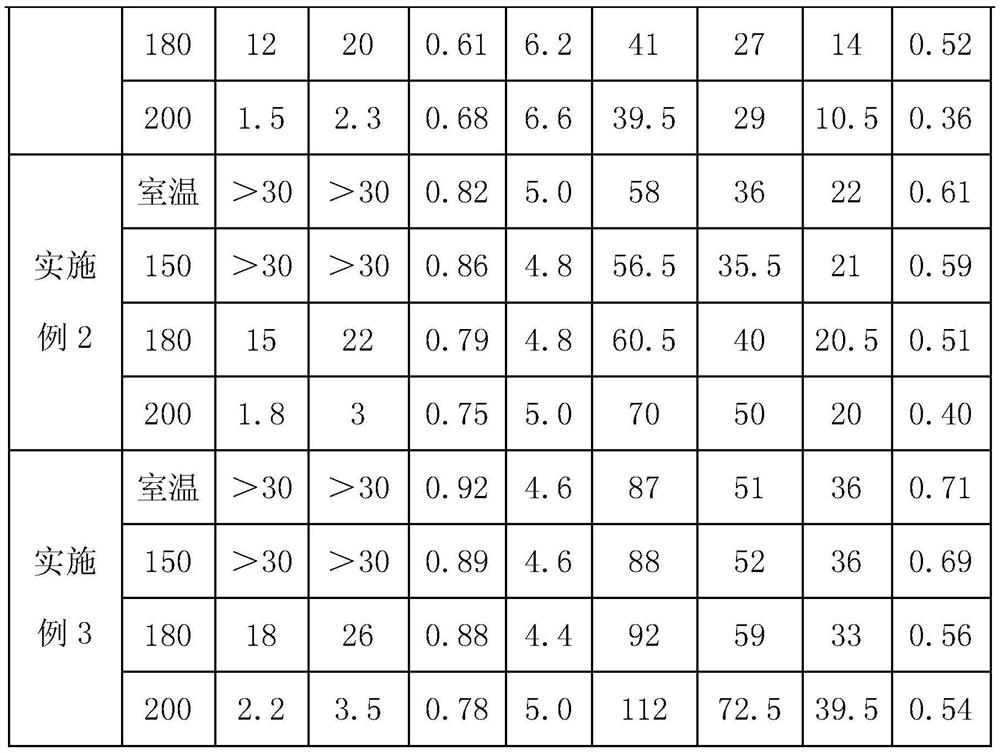

Embodiment 1

[0062] Take 100 parts of clear water, add 0.3 parts of low molecular weight anti-high temperature foam stabilizer TFS to it, stir with a low-speed stirrer for 2 hours; 3 parts of shell plant fiber powder, fully stirred for 5 minutes, and left to stand for 2 hours to form a temperature-resistant hard gum base liquid. Accurately weigh 2 parts of temperature-resistant sodium bentonite, 0.08 part of sodium carbonate, 0.1 part of sulfonate polymer fluid loss reducer, 0.2 part of sodium α-olefin sulfonate, 0.1 part of sodium dodecylbenzenesulfonate, nitrile silicon reducer Mix 2 parts of fluid loss agent and 1 part of polyoxyethylene-based fluid loss reducer evenly, add the above-mentioned temperature-resistant hard rubber base solution while stirring, and stir with a low-speed strong stirrer at 900r / min for 6h.

Embodiment 2

[0064] Take 100 parts of clear water, add 0.3 parts of low molecular weight anti-high temperature foam stabilizer TFS to it, stir with a low-speed stirrer for 2 hours; after uniform dispersion and dissolution, add 0.1 part of alkylphenol polyoxyethylene ether, sorbitan monooleate 0.1 part, fully stirred for 15 minutes; added 2 parts of modified hard shell plant fiber powder, 1 part of modified mica fiber powder, fully stirred for 10 minutes, and stood for 2 hours to form a temperature-resistant hard rubber base liquid. Accurately weigh 3 parts of temperature-resistant sodium bentonite, 0.1 part of sodium carbonate, 0.3 part of comb polymer fluid loss reducer, 0.2 part of α-olefin sulfonate sodium, 0.1 part of sodium dodecylbenzene sulfonate, nitrile silicon filter reducer 2 parts of loss agent, 1 part of polyoxyethylene-based fluid loss reducer, 1 part of sulfonated phenolic resin, mix evenly, add the above-mentioned temperature-resistant hard rubber base liquid while stirring,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com