Device and method for dynamically depositing second-generation high-temperature superconducting tape

A high-temperature superconducting tape, dynamic deposition technology, applied in the use of superconducting elements, equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, etc. It is difficult to replace high-temperature superconducting tapes and other problems, and achieves the effect of good electrical properties and smooth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention uses yttrium acetate, barium acetate and copper acetate as raw materials to prepare a precursor solution, and puts the precursor solution in the precursor solution tank 3 . In the present invention, the molar ratio of yttrium acetate, barium acetate and copper acetate is 1:2:3; the solvent of the precursor solution is preferably methanol; the three metal elements of yttrium, barium and copper in the precursor solution The total ion concentration is preferably 1.5-4.5 mol / L, more preferably 3-4.5 mol / L, and the thickness of the precursor on the metal substrate can be controlled by adjusting the concentration of the precursor solution. In the present invention, the preparation method of the precursor solution preferably includes the following steps:

[0051] mixing yttrium acetate, barium acetate and copper acetate, and dissolving them in an aqueous solution of trifluoroacetic acid to obtain a first mixed solution;

[0052] The first mixed solution ...

Embodiment 1

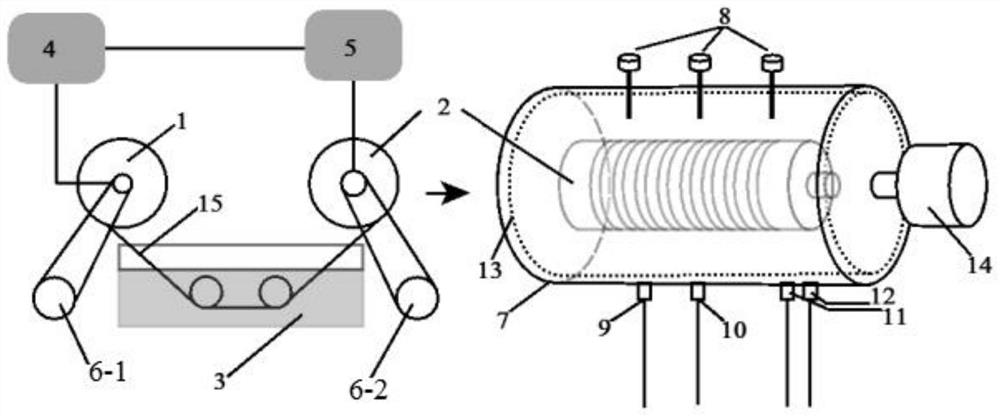

[0063] A device for dynamically depositing second-generation high-temperature superconducting tapes, such as figure 1 As shown, including dynamic winding system and vacuum heat treatment furnace;

[0064] The dynamic winding system includes an unwinding device 1, a winding frame 2, and a precursor liquid tank 3 located below the unwinding device 1 and the winding frame 2; the unwinding device 1 and the winding frame 2 are respectively connected to servo motors 6-1 and a servo motor 6-2; the unwinding device 1 is provided with a tension control system 4, the winding skeleton 2 is provided with a line speed detection device 5, and the tension control system 4 and the line speed detection device 5 are connected by a data line;

[0065] The vacuum heat treatment furnace includes a vacuum furnace cavity 7 and a rotating device 14; the outer wall of the vacuum furnace cavity 7 is provided with a temperature control thermocouple 8, an air inlet 9, an air extraction port 10, a cooling...

Embodiment 2

[0073] A device for dynamically depositing a second-generation high-temperature superconducting tape, which is the same as in Example 1, using the device to dynamically deposit a second-generation high-temperature superconducting tape, the method is as follows:

[0074] (1) Configure the precursor solution: weigh yttrium acetate, barium acetate and copper acetate according to the molar ratio of 1:2:3, mix the yttrium acetate, barium acetate and copper acetate and dissolve them in deionized water containing 10mol% trifluoroacetic acid ( The molar ratio of trifluoroacetic acid to barium acetate is 2.5:1) to form a solution; after stirring the prepared solution for 1 h with a magnetic stirrer, the solvent was evaporated by a rotary evaporator to obtain a coarse gel; methanol was added to the obtained crude gel In the gel, after being stirred by a magnetic stirrer for 0.5h, the solvent was evaporated by a rotary evaporator to obtain a purified gel; finally, methanol was added to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tension | aaaaa | aaaaa |

| Critical current | aaaaa | aaaaa |

| Critical current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com