Method for preparing nano material layer by self-assembling diphenylacetylene on surface of metal single crystal

A technology of diphenylacetylene and nanomaterials, applied in the field of nanomaterials, can solve the problem of inability to prepare two-dimensional porous nanomaterials, and achieve the effect of orderly structure and uniform size of pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

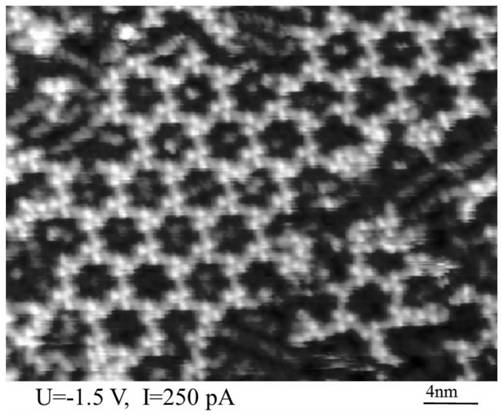

[0017] Example 1: In this embodiment, the method for preparing a two-dimensional porous nanomaterial on the surface of a metal single crystal based on the self-assembly of tolanylene molecules is carried out according to the following steps:

[0018] 1. Place the Au(111) single crystal substrate in the ultra-high vacuum preparation chamber of a low-temperature scanning tunneling microscope (LT-STM UNISOKU SPM1200), and the vacuum degree in the chamber is 3.0×10 -10 torr, the temperature is room temperature. At an argon pressure of 1.0 x 10 - 5 Under mbar, there is a discharge electrode in the preparation chamber. The discharge electrode is controlled by the argon chamber controller (PREVAC IS40-PS), and the discharge electrode connected to the vacuum chamber is applied to the voltage by the argon chamber controller (PREVAC IS40-PS). , current, under the condition that the high voltage is 1KeV and the current is 26mA, argon ion sputtering is performed on the surface of Au(111...

Embodiment 2

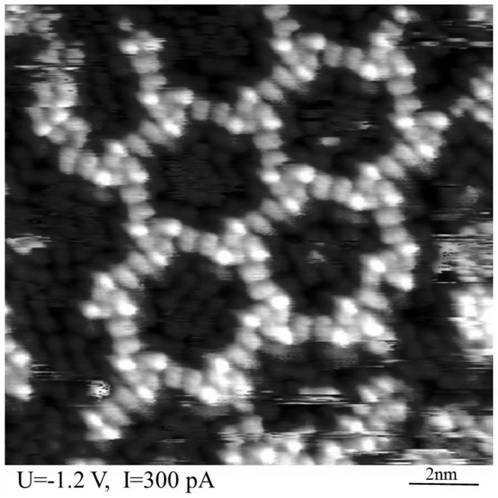

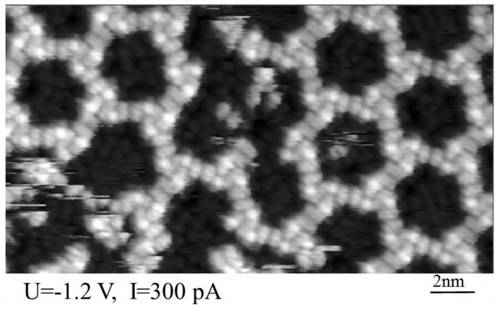

[0024] Example 2: This implementation mode is different from Example 1 in that: the metal single crystal described in step 2 is heated to 53° C., and the deposition time is 3 s. Other steps and parameters are the same as in Example 1. The nanomaterials have a pore size of 3.39nm, an average height of 120pm, and are uniformly arranged. Diphenylacetylene first forms a disordered monomolecular layer on the surface of the metal single crystal, and then forms a ring-shaped protruding two-dimensional hole-like nanomaterial region on the surface of the first layer. The second layer is composed of The ring area formed by the self-assembly of tolanne molecules through hydrogen bond interaction, the middle of the ring area is the hole that exposes the first layer, and the hole surrounded by the assembled molecules and the assembled molecules (ie the second layer) are on the surface of the first layer The coverage rate is 18%.

Embodiment 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the deposition time in step 2 is 3s. The nanomaterials have a pore size of 3.39nm, an average thickness of 0.95nm, an average height of 120pm, and are uniformly arranged. Diphenylacetylene first forms a disordered monomolecular layer on the surface of the metal single crystal, and then forms a ring-shaped protruding two-dimensional hole-like nanomaterial region on the surface of the first layer. The second layer is composed of The ring area formed by the self-assembly of tolanne molecules through hydrogen bond interaction, the middle of the ring area is the hole that exposes the first layer, and the hole surrounded by the assembled molecules and the assembled molecules (ie the second layer) are on the surface of the first layer The coverage rate is 26%.

[0026] The patent of the present invention is to provide a method for preparing a two-dimensional porous nanomaterial on the surface of a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com