Preparation and application of bismuth vanadate/Vo-FeNiOOH composite photo-anode

A technology of compounding light and bismuth vanadate, applied in the field of photoelectrochemistry, can solve the problems of severe recombination of electrons and holes, loose coupling between semiconductor and electrocatalyst, thick electrocatalyst, etc., and achieve simple method, fast water oxidation kinetics, Effect of improving PEC performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The method for preparing a bismuth vanadate / Vo-FeNiOOH composite photoanode of the present invention will be further described below through specific implementation methods.

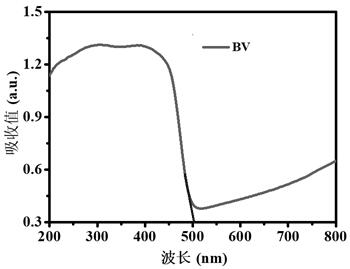

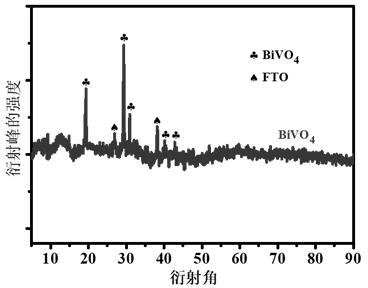

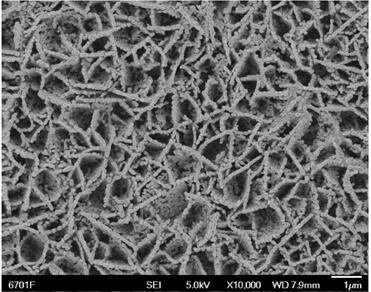

[0032] (1) Preparation of BiVO 4 electrode

[0033] Preparation of BiVO on FTO substrates by a combination of electrodeposition and annealing 4 film. Weigh 3.32 g KI dissolved in 50 mL ultrapure water and stir to dissolve, then add HNO 3 Its pH was adjusted to 1.7. Subsequently, 0.97 g Bi(NO 3 ) 3 ·5H 2 O, stirred vigorously for 20 min to form a reddish-orange transparent solution. Weigh 0.4972 g of p-benzoquinone and dissolve it ultrasonically in 20 mL of ethanol to obtain the ethanol solution of p-benzoquinone. Add the ethanol solution of p-benzoquinone to the above-mentioned red-orange transparent solution, mix and stir for 30 min, and then use a three-electrode system for electrodeposition , with FTO as the working electrode, Ag / AgCl electrode as the reference electrode, and Pt sheet as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com