Method for uniformly refining low-temperature lead-free glass powder by using ultrahigh-pressure microjet and application thereof

A lead-free glass powder and micro-jet homogenization technology, applied in the chemical industry, can solve the problems of inconsistent particle size and distribution of oxide powder, uneven particle size, and difficult control of fineness, etc., to overcome long grinding time, Highly uniform particle size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

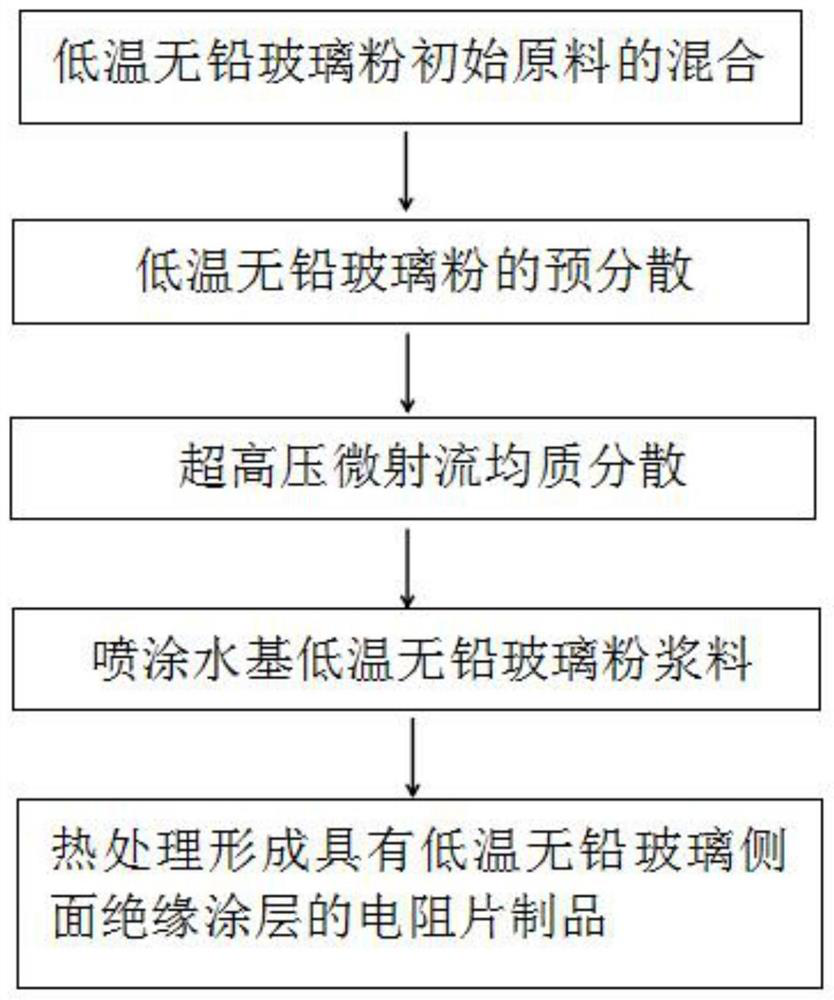

[0029] In this embodiment, a method for uniformly refining low-temperature lead-free glass powder using ultra-high pressure micro-jet comprises the following steps:

[0030] (1) according to following composition and mass percentage composition, the initial powder of preparation low-temperature lead-free glass powder, as raw material:

[0031] Bi 2 o 3 :70.0wt%, ZnO:22.5wt%, Sb 2 o 3 : 1.0wt%, SiO 2 :2.3wt%, CuO: 1.6wt%, Al 2 o 3 : 2.2wt%, Mn 3 o 4 :0.4wt%;

[0032] (2) Mix the above raw materials, deionized water and dispersant according to the mass ratio of 1000:800:5, use high-speed dispersion to pre-disperse for 15 minutes, and set the pre-dispersion rate to 900r / min. The jet homogenizer performs homogenization treatment 5 times, and the treatment pressure is set at 80MPa; after the homogenization treatment process is completed, it is filtered through a 300-mesh screen to obtain a slurry of low-temperature lead-free glass powder with stable dispersion.

[0033] A...

Embodiment 2

[0037] In this embodiment, a method for uniformly refining low-temperature lead-free glass powder using ultra-high pressure micro-jet comprises the following steps:

[0038] (1) according to following composition and mass percentage composition, the initial powder of preparation low-temperature lead-free glass powder, as raw material:

[0039] Bi 2 o 3 :70.0wt%, ZnO:22.5wt%, Sb 2 o 3 : 1.0wt%, SiO 2 :2.3wt%, CuO: 1.6wt%, Al 2 o 3 : 2.2wt%, Mn 3 o 4 :0.4wt%;

[0040] (2) Mix the above raw materials, deionized water and dispersant according to the mass ratio of 1000:800:5, use high-speed dispersion to pre-disperse for 15 minutes, and set the pre-dispersion rate to 1000r / min. The jet homogenizer performs homogenization treatment 3 times, and the treatment pressure is set at 110MPa; after the homogenization treatment process is completed, it is filtered through a 300-mesh screen to obtain a slurry of low-temperature lead-free glass powder with stable dispersion.

[0041]...

Embodiment 3

[0045] In this embodiment, a method for uniformly refining low-temperature lead-free glass powder using ultra-high pressure micro-jet comprises the following steps:

[0046] (1) according to following composition and mass percentage composition, the initial powder of preparation low-temperature lead-free glass powder, as raw material:

[0047] Bi 2 o 3 :72.5wt%, ZnO: 19.0wt%, Sb 2 o 3 :1.5wt%, SiO 2 :2.6wt%, CuO: 1.6wt%, Al 2 o 3 : 2.2wt%, Mn 3 o 4 :0.6wt%;

[0048] (2) Mix the above raw materials, deionized water and dispersant according to the mass ratio of 1000:800:5, use high-speed dispersion to pre-disperse for 15 minutes, and set the pre-dispersion rate to 1000r / min. The jet homogenizer performs homogenization treatment 3 times, and the treatment pressure is set at 110MPa; after the homogenization treatment process is completed, it is filtered through a 300-mesh screen to obtain a slurry of low-temperature lead-free glass powder with stable dispersion.

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com