Composite ceramic with honeycomb fiber structure and preparation method of composite ceramic

A composite ceramic and honeycomb fiber technology, applied in ceramic products, ceramic molding machines, dental preparations, etc., can solve the problems that the strength and toughness of ceramic materials cannot be taken into account, and the denture materials cannot take into account the aging and phase transformation toughness. Mechanical properties, improved aesthetics, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

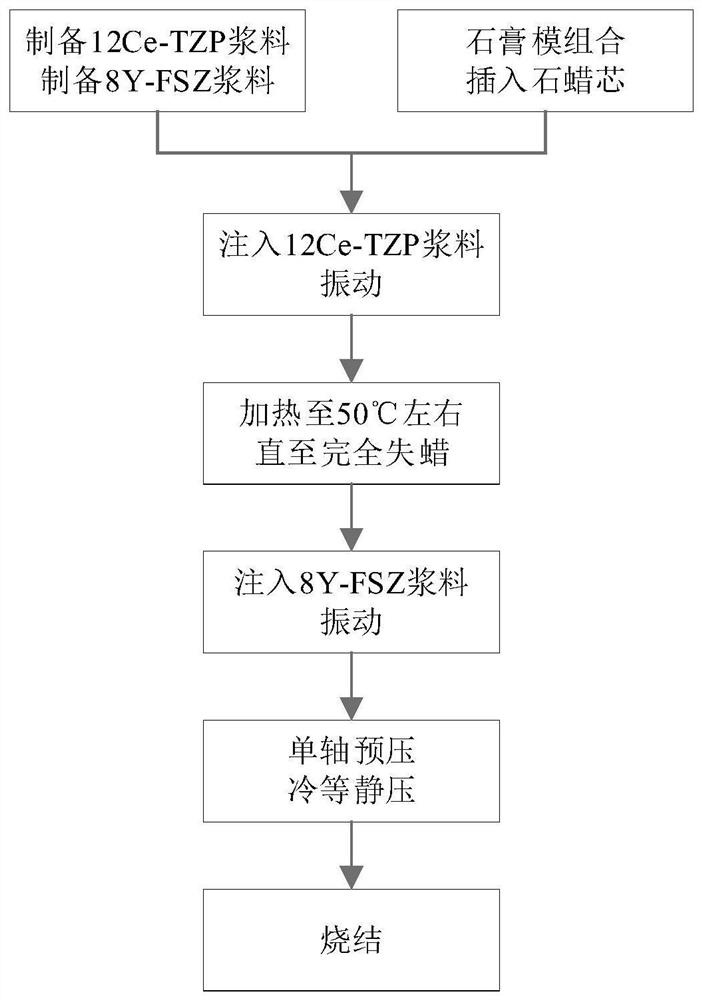

[0046] The preparation method of the composite ceramic of the above-mentioned honeycomb fiber structure, comprises the following steps:

[0047] (S-1) preparing high-strength ceramic slurry and high-toughness ceramic slurry, the ceramic slurry is a slurry composed of ceramic powder, binder, sintering aid and colorant;

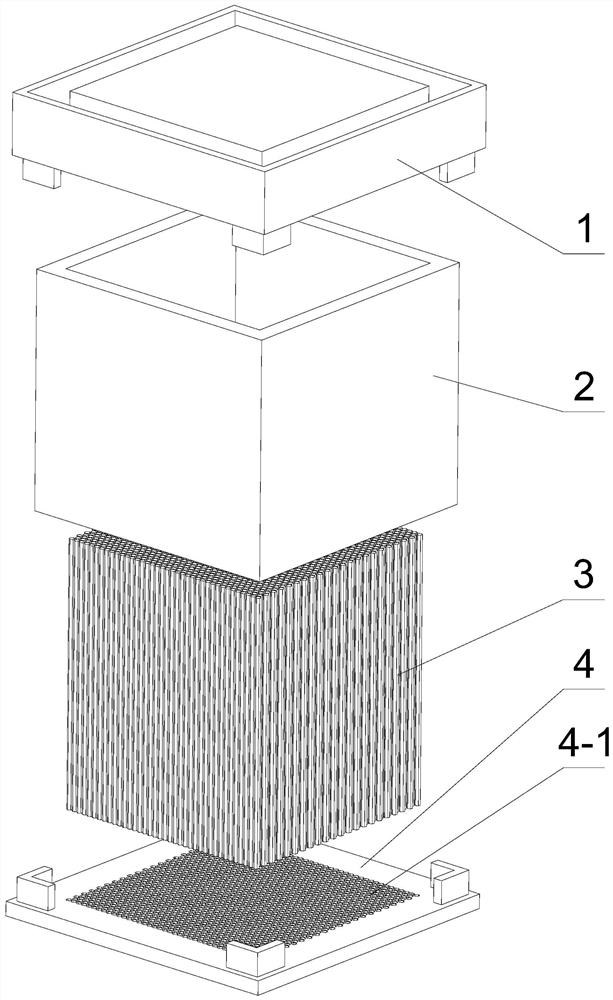

[0048] (S-2) Insert the paraffin core 3 into the casting mold to occupy the space, inject the high-strength ceramic slurry into the casting mold, and after the high-strength ceramic slurry is solidified, heat the paraffin core 3 to melt and flow out, forming the cell wall B and the The compartment enclosed by the cell wall B; e.g. image 3 , Figure 4 and Figure 5 As shown, the casting mold is a plaster mold, including an upper mold 1, a middle mold 2 and a lower mold 4. The upper mold 1 includes an upper mold body 1-0 and a paraffin core fixing hole 1-2 provided on the upper mold body 1-0. and the grouting port 1-1, the lower mold 4 includes a lower mold b...

Embodiment 1

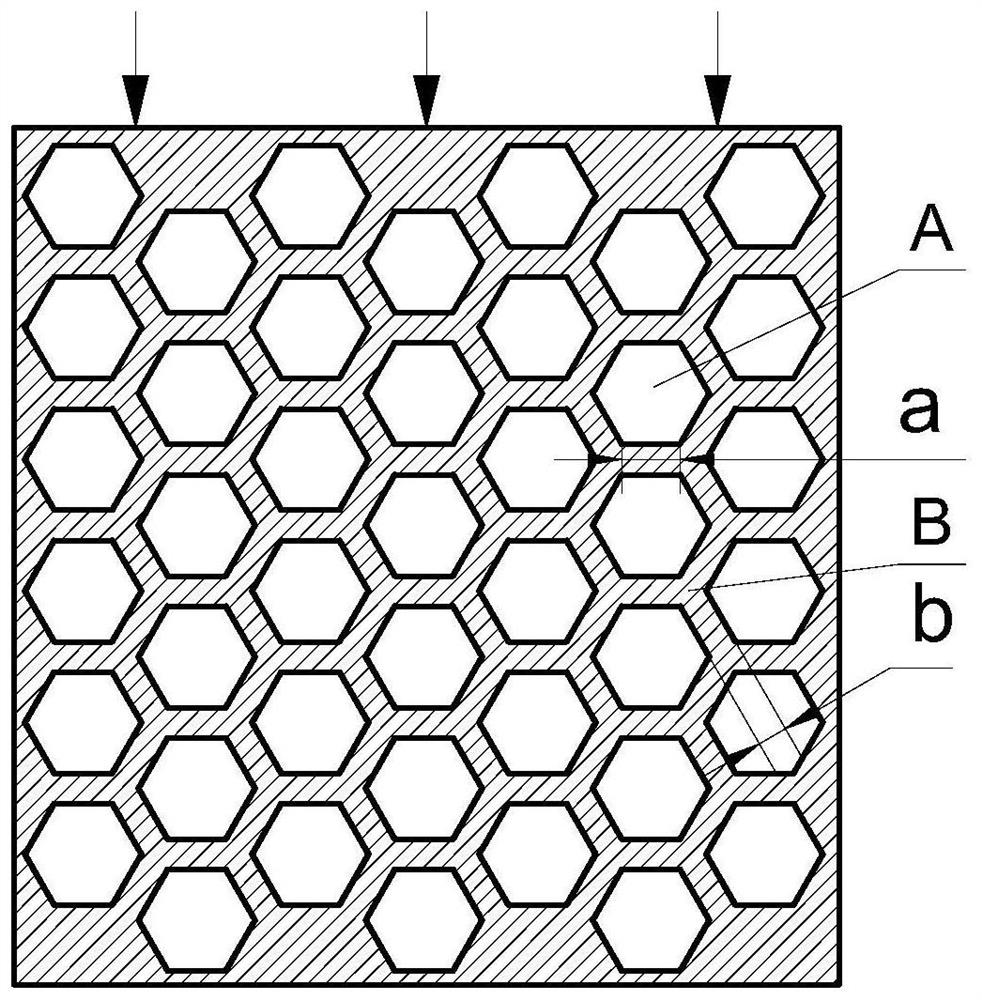

[0053] A composite ceramic with a honeycomb fiber structure, specifically a composite ceramic for an all-ceramic denture, can achieve maximum coordination of strength, toughness, light transmittance and anti-aging properties; its structure is as follows figure 1 As shown, the composite ceramic of honeycomb fiber structure is composed of regular hexagonal cell body A and cell wall B. The material of cell wall B is high-strength ceramics, the material of cell body A is high-toughness ceramics, and cell body A plays the main bearing role. The cell wall mainly plays a toughening role. The combination of this "hard phase" and "soft phase" can effectively hinder crack propagation through crack deflection and bridging. The two complement each other's advantages in strength, toughness, light transmittance and anti-aging. balance in performance. In this example, the cell body A is composed of 8 mol% Y 2 O 3 -ZrO 2 (8Y-FSZ), an appropriate amount of binder, a small amount of sinterin...

Embodiment 2

[0061] This example is a honeycomb fiber composite ceramic. The difference from Example 1 is that the diameter of the regular hexagonal inscribed circle of the cell body of the composite ceramic is 2 mm. The flexural strength of the composite ceramic is 1040 MPa, and the fracture toughness is 1040 MPa. 11.7MPa.m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com