High-temperature and high-pressure-resistant rubber tube medium rubber and inner rubber comprehensive accelerator and preparation method thereof

A rubber tube and high temperature resistant technology, applied in the field of rubber product processing aids, can solve problems such as unsatisfactory effects and rubber product quality problems, achieve excellent mechanical and physical properties, good antibacterial and mildew resistance, and improve high and low temperature resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

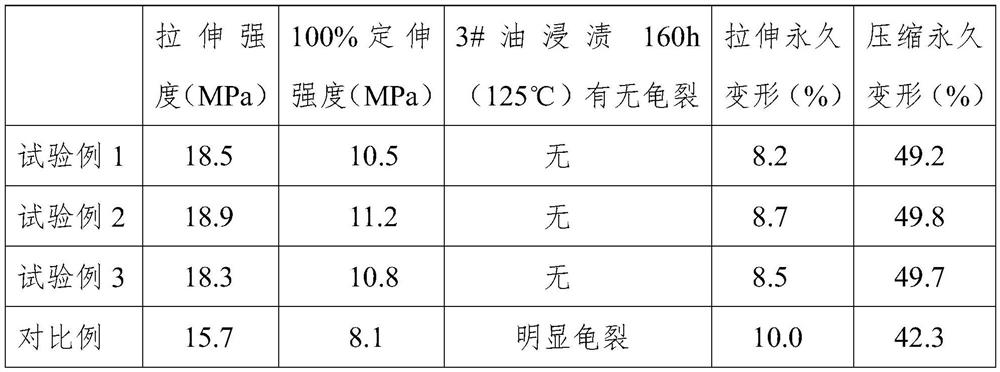

Examples

Embodiment 1

[0028] A high-temperature and high-pressure resistant rubber tube rubber and inner rubber comprehensive accelerator, including the following raw materials in parts by weight: 20 parts of mixed rubber material, 0.8 parts of reinforcing agent, 1.5 parts of nano filler, 2.5 parts of performance enhancer, 1.0 parts of Nano molybdenum disulfide, 10 parts of zinc diphosphate, 12 parts of sulfenamide accelerator, 2 parts of thiazole accelerator, 5 parts of N-cyclohexylthiophthalimide, 12 parts of 4,4'- Dithiodimorpholine, 3 parts anti-blooming agent, 1 part dispersant and 25 parts insoluble sulfur.

[0029] The mixed rubber is prepared by mixing fluorine rubber and nitrile rubber at a mass ratio of 1:1.5.

[0030] The reinforcing agent is made of nano-carbon black.

[0031] The nano-filler is prepared by mixing nano-cerium oxide and nano-titanium dioxide at a mass ratio of 2:1.

[0032] The preparation method of performance enhancer is:

[0033] Weigh an appropriate amount of poro...

Embodiment 2

[0044] A high-temperature and high-pressure resistant rubber tube rubber and inner rubber comprehensive accelerator, including the following raw materials in parts by weight: 23 parts of mixed rubber material, 1.0 parts of reinforcing agent, 1.8 parts of nano filler, 3.0 parts of performance enhancer, 1.2 parts Nano molybdenum disulfide, 12 parts of zinc diphosphate, 15 parts of sulfenamide accelerator, 5 parts of thiazole accelerator, 8 parts of N-cyclohexylthiophthalimide, 16 parts of 4,4'- Dithiodimorpholine, 6 parts anti-blooming agent, 2 parts dispersant and 30 parts insoluble sulfur.

[0045] The mixed rubber is prepared by mixing fluorine rubber and nitrile rubber at a mass ratio of 1:1.8.

[0046] The reinforcing agent is made of nano silicon dioxide.

[0047] The nano-filler is prepared by mixing nano-cerium oxide and nano-titanium dioxide at a mass ratio of 2.5:1.

[0048] The preparation method of performance enhancer is:

[0049] Weigh an appropriate amount of por...

Embodiment 3

[0060] A high-temperature and high-pressure resistant rubber tube rubber and inner rubber comprehensive accelerator, including the following raw materials in parts by weight: 26 parts of mixed rubber material, 1.2 parts of reinforcing agent, 2.0 parts of nano filler, 3.6 parts of performance enhancer, 1.5 parts Nano molybdenum disulfide, 15 parts of zinc diphosphate, 20 parts of sulfenamide accelerator, 8 parts of thiazole accelerator, 10 parts of N-cyclohexylthiophthalimide, 20 parts of 4,4'- Dithiodimorpholine, 10 parts of anti-blooming agent, 3 parts of dispersant and 35 parts of insoluble sulfur.

[0061] The mixed rubber is prepared by mixing fluorine rubber and nitrile rubber according to the mass ratio of 1:2.0.

[0062] The reinforcing agent is nano-carbon black.

[0063] The nano-filler is prepared by mixing nano-cerium oxide and nano-titanium dioxide at a mass ratio of 3:1.

[0064] The preparation method of performance enhancer is:

[0065] Weigh an appropriate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com