Film removing agent for IC carrier plate and application of film removing agent

A film-removing agent and carrier technology, which is applied in detergent compounding agent, detergent composition, surface-active detergent composition, etc., can solve the problem of sheet line falling off, poor film-removing effect, and high requirements for equipment and reaction conditions, etc. problem, to achieve the effect of efficient removal and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

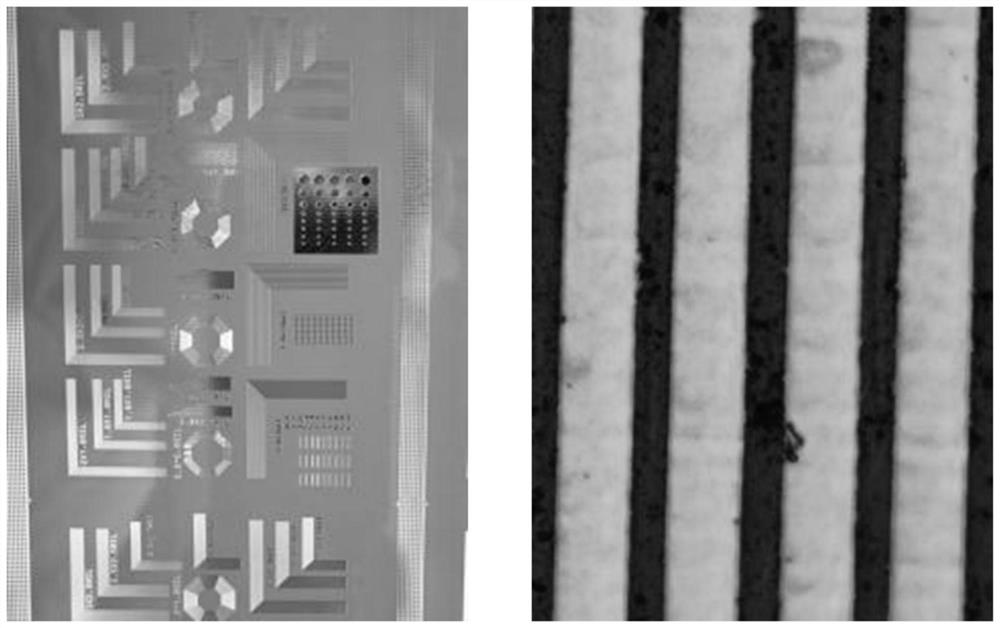

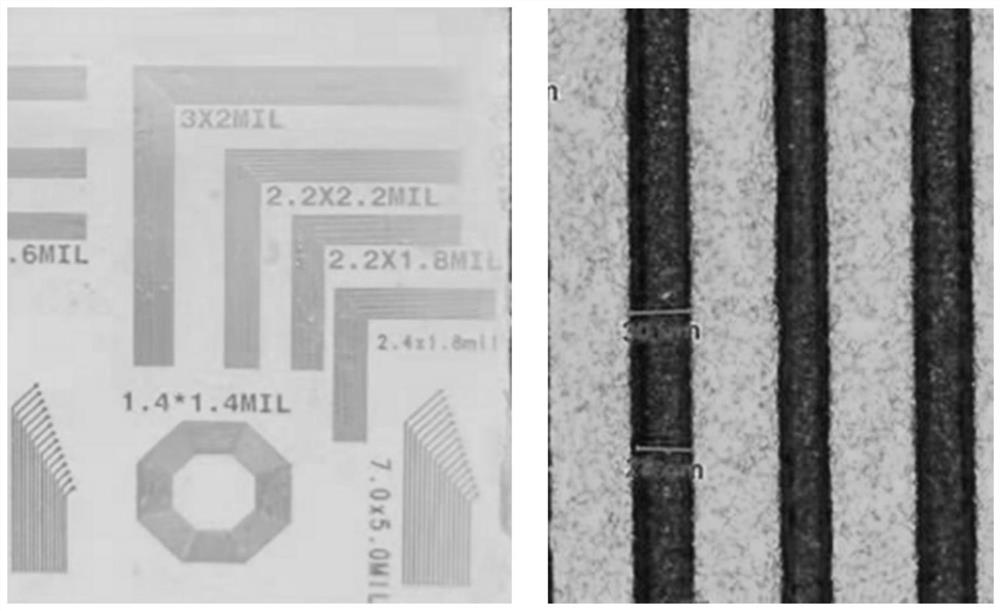

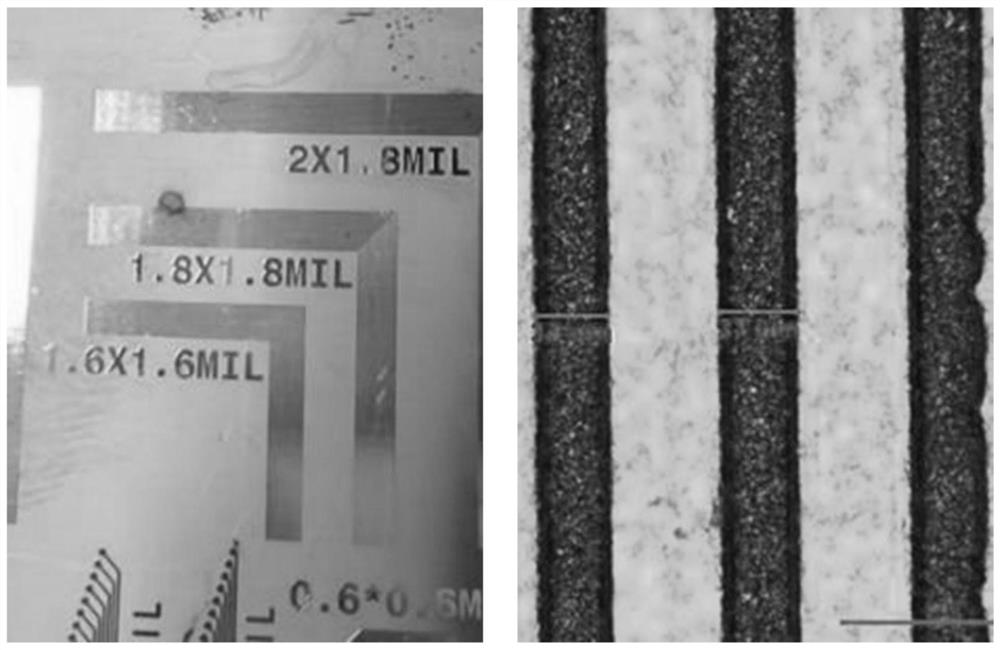

Image

Examples

Embodiment 1

[0037] An embodiment of the film remover for IC substrates of the present invention includes the following components in mass percentage: 15% film remover A, 9% film remover B and the remainder of water; the film remover A Comprising the following components in mass percentage: 13% sodium hydroxide, 12% potassium hydroxide, 5% sodium carbonate, 22% triethylenetetramine, 5% dimethylamine, 8% ethylene glycol monobutyl ether and the rest Measure water; the film remover B includes the following components in mass percentage: 3% polyoxypropylene glyceryl ether, 9% dimethyl phosphoric acid aminomethanesulfonic acid, 2% polynaphthaldehyde sulfonic acid sodium salt, 8% 2-hydroxyphosphonoacetic acid, 2% N-lauroyl sarcosine, 0.8% iminodiacetic acid, 25% triethylamine and the balance water.

Embodiment 2

[0039] An embodiment of the film remover for IC substrates of the present invention includes the following components in mass percentage: 20% film remover A, 5% film remover B and the remainder of water; the film remover A Comprising the following components in mass percentage: 14% sodium hydroxide, 11% potassium hydroxide, 5% sodium carbonate, 20% triethylenetetramine, 2% tetraethylenepentamine, 6% dimethylamine, 10% ethyl Glycol monobutyl ether and the remaining amount of water; the film remover B includes the following components in mass percentage: 3% polyoxypropylene glyceryl ether, 10% dimethyl phosphoric acid, 2.3% polynaphthaldehyde Sulfonic acid sodium salt, 5% 2-hydroxyphosphonoacetic acid, 3% S-carboxyethylsulfosuccinic acid, 1% N-lauroyl sarcosine, 0.9% iminodiacetic acid, 28% triethylamine and other Measure water.

Embodiment 3

[0041]An embodiment of the IC carrier film remover of the present invention includes the following components in mass percentage: 12% film remover A, 10% film remover B and the remainder of water; the film remover A Comprising the following components in mass percentage: 13% sodium hydroxide, 13% potassium hydroxide, 5% sodium carbonate, 23% tetraethylenepentamine, 6% dimethylamine, 10% ethylene glycol monobutyl ether and the rest Measure water; the film remover B includes the following components in mass percentage: 3.5% polyoxypropylene glyceryl ether, 9% dimethyl phosphoric acid aminomethanesulfonic acid, 1% polynaphthaldehyde sulfonic acid sodium salt, 1% Sodium N-oleoylmethyl taurate, 9% 2-hydroxyphosphonoacetic acid, 1% N-lauroyl sarcosine, 0.4% iminodiacetic acid, 0.3% tetrasodium glutamate diacetate, 20% trisodium Ethylamine and the remainder of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com