Color fixing fabric and preparation method thereof

A technology of fabrics and colorants, applied in the field of color-fixing fabrics and their preparation, can solve the problems of the perceived color of the fabric becoming lighter, affecting the appearance, silicone oil is not washable, etc., and achieve the effect of smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

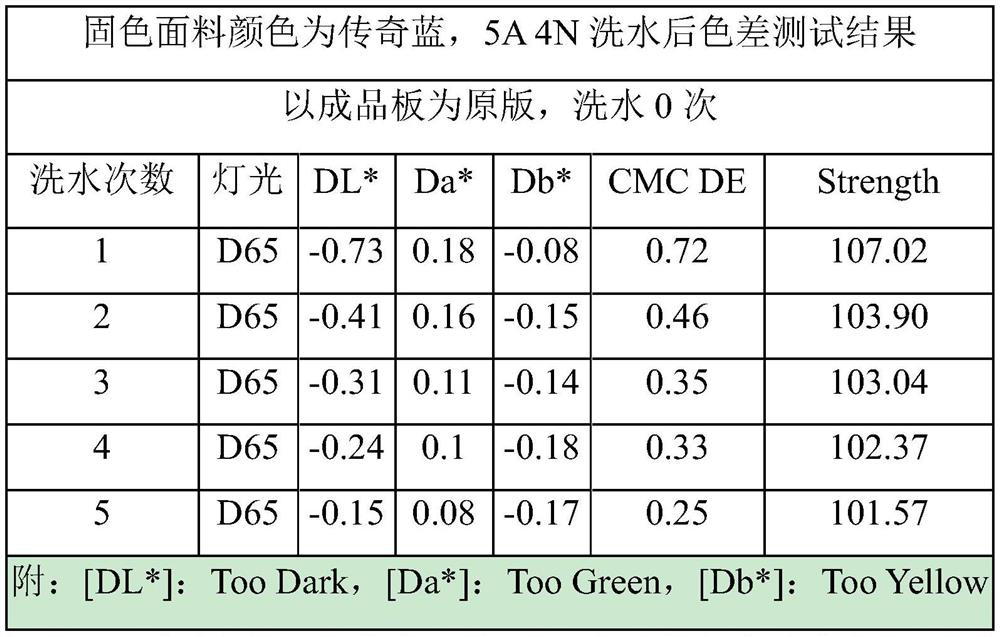

Image

Examples

Embodiment 1

[0032] A preparation method for color-fixing fabric, comprising the steps of:

[0033] (S1), take the woven blank, after boiling the cloth, add dyeing material liquid for dyeing treatment, and then shape the dry cloth;

[0034] (S2), the woven fabric after the shaped dry cloth is subjected to shaping treatment and color fixing treatment sequentially with white shaping material liquid and color fixing material liquid, and then using a shrinking machine to carry out heavy pressing and leveling treatment to obtain the color fixing fabric.

[0035] The fabric is Roman cloth.

[0036] The white sizing liquid includes the following dosage components: 0.5 g / L of white pigment, 1 g / L of penetrating agent and 30 g / L of methyl methacrylate adhesive.

[0037] The penetrant is sulfated castor oil.

[0038] The white pigment is titanium dioxide.

[0039] The sizing treatment is to add the white sizing material liquid into the sizing machine and treat at 145° C. for 20 minutes.

[0040]...

Embodiment 2

[0047] A preparation method for color-fixing fabric, comprising the steps of:

[0048] (S1), take the woven blank, after boiling the cloth, add dyeing material liquid for dyeing treatment, and then shape the dry cloth;

[0049] (S2), the woven fabric after the shaped dry cloth is subjected to shaping treatment and color fixing treatment sequentially with white shaping material liquid and color fixing material liquid, and then using a shrinking machine to carry out heavy pressing and leveling treatment to obtain the color fixing fabric.

[0050] The fabric is Roman cloth.

[0051] The white sizing liquid includes the following dosage components: 0.1 g / L of white pigment, 1 g / L of penetrating agent and 10 g / L of methyl methacrylate adhesive.

[0052] The penetrant is sodium α-olefin sulfonate.

[0053] The white pigment is zinc oxide.

[0054] The sizing treatment is to add the white sizing material liquid into the sizing machine and treat at 140° C. for 15 minutes.

[0055]...

Embodiment 3

[0062] A preparation method for color-fixing fabric, comprising the steps of:

[0063] (S1), take the woven blank, after boiling the cloth, add dyeing material liquid for dyeing treatment, and then shape the dry cloth;

[0064] (S2), performing shaping treatment and color-fixing treatment sequentially on the woven base after the shaped dry cloth with a white shaping material liquid and a color-fixing material liquid, to obtain the color-fixing fabric.

[0065] The fabric is Roman cloth.

[0066] The white sizing liquid includes the following dosage components: 1.8 g / L of white pigment, 1 g / L of penetrating agent and 50 g / L of methyl methacrylate adhesive.

[0067] The penetrant is sodium secondary alkyl sulfate.

[0068] The white pigment is antimony oxide.

[0069] The sizing treatment is to add the white sizing material liquid into the sizing machine and treat at 150° C. for 25 minutes.

[0070] The color-fixing material solution includes the following dosage components:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com