Method for testing leakage rate of air seal of fuel cell air compressor

A test method and fuel cell technology, applied in pump testing, mechanical equipment, machines/engines, etc., can solve the problem that it is difficult to effectively and accurately measure the air outlet flow of the air compressor, and the aerodynamic characteristics of the air compressor system cannot be obtained. It is impossible to effectively measure the leakage of the air compressor system sealing structure, so as to achieve the effect of easy promotion and utilization, accurate and efficient detection methods, and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

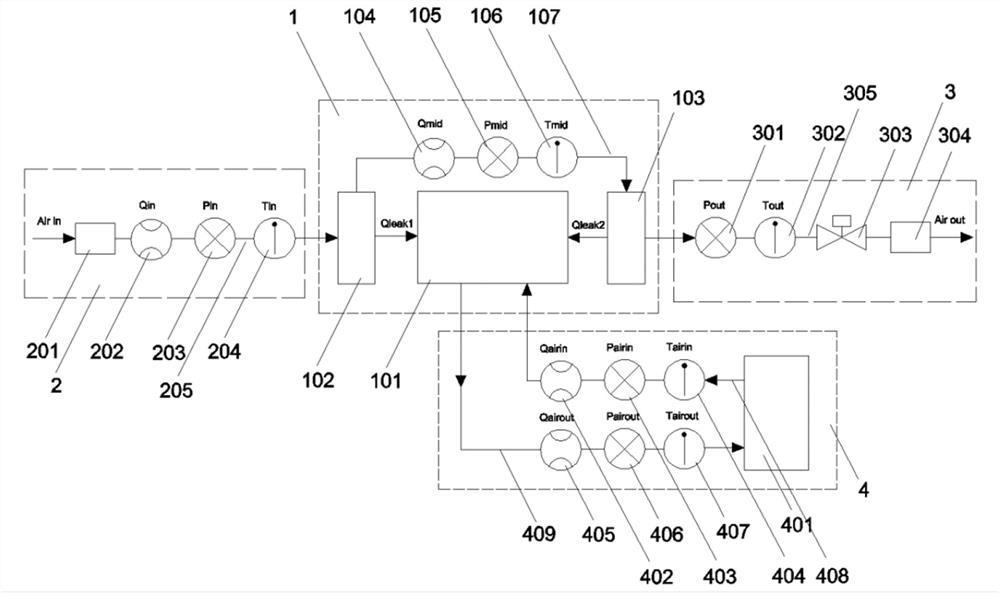

[0040] Such as figure 1 As shown, the test system and structure based on the test method of the present invention include: an air compressor module 1 , a main air intake mechanism 2 , a main air outlet mechanism 3 , and a cooling air mechanism 4 .

[0041] The air compressor module 1 includes: an air compressor body 101, an air compressor stage 1 pressurization and sealing structure 102, an air compressor stage 2 pressurization and sealing structure 103, a first flow meter 104, a first pressure sensor 105, The first temperature sensor 106, and the above-mentioned structures are connected in series by an intermediate pipe 107.

[0042] Wherein the main air intake mechanism 2 includes: an air filter 201, a second flow meter 202, a second pressure sensor 203, and a second temperature sensor 204, and an air intake pipeline 205 is used to connect each component in series.

[0043] The main air outlet mechanism 3 includes: a third pressure sensor 301, a third temperature sensor 302...

Embodiment 2

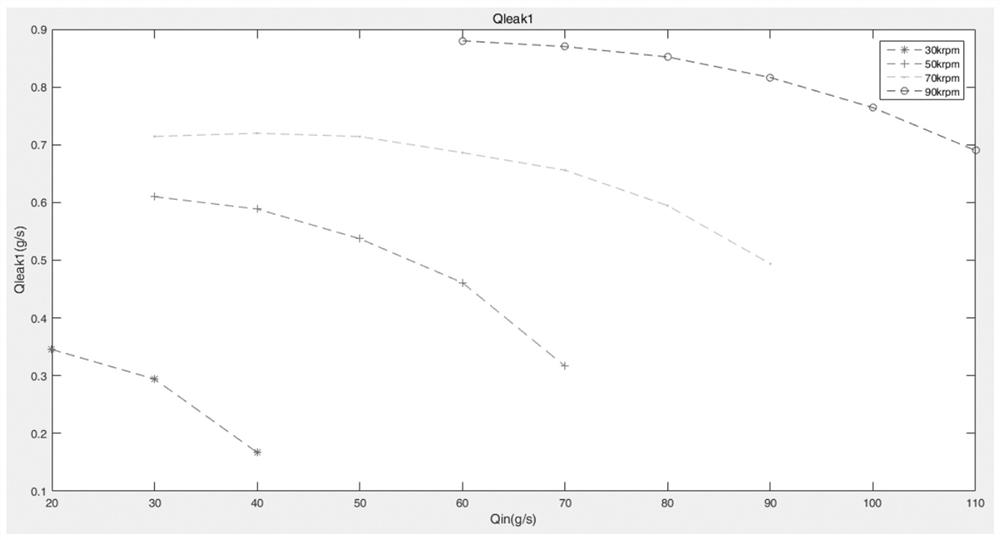

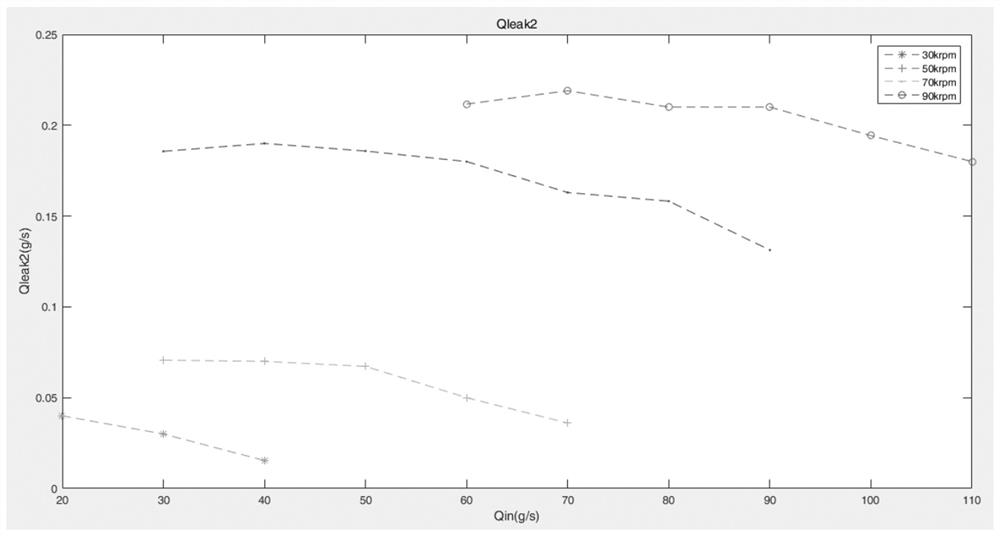

[0071] (1) From the idle speed of 30000rpm to the peak speed of the motor of 90000rpm, the speed vector N is equally spaced: 30000, 5000, 7000, 90000rpm;

[0072] From 0 to the highest flow rate of 120g / s, it is equally spaced into the flow vector Qin of the main gas path inlet: 0, 10, 20, ..., 120g / s;

[0073]Take the Qin vector as the abscissa and the N vector as the ordinate to establish a test condition matrix, as shown in the following table:

[0074]

[0075] (2) The air compressor uses Id=0, speed loop control, adjusts the opening of the air outlet valve, adjusts the inlet flow of the main air circuit to the specified value, and tests the above working conditions respectively. The air cooling system can automatically read the outlet pressure of the air compressor Pout, and calculate the air-cooling outlet pressure target value P*airin in real time according to the following formula, as the closed-loop control value of the air-cooling outlet pressure, and set the air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com