Method for extracting, separating and purifying micro-plastics in soil

A technology of microplastics and soil, applied in the field of soil chemical analysis, can solve the problems of insufficient extraction, high extraction efficiency of sandy soil samples, low efficiency of clay and loam soil, etc., achieve small particle size, rich humus content, strong adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Step 1. Soil sample pretreatment

[0056] Soil samples are classified according to texture, divided into sandy soil, loamy soil and clay; remove large particles of impurities, such as crushed stones, plant roots, etc. in the sample, and then sieve, with a sieve aperture of 5.0 mm to remove plastic particles larger than 5 mm and other impurities to obtain pretreated soil samples.

[0057] Carbonate and organic matter in the pretreated soil samples were measured, the results are as follows:

[0058] Carbonate:

[0059] Carbonate in sand is 0.065g / 100g, so CO 3 2- 0.004g / 100g;

[0060] Carbonate in loam is 0.131g / 100g, so CO 3 2- 0.008g / 100g;

[0061] Carbonate in clay is 0.128g / 100g, so CO 3 2- It is 0.0078g / 100g.

[0062] Organic matter:

[0063] 100g of sand contains 0.50g of organic matter,

[0064] 100g of loam soil contains 2.82g of organic matter,

[0065] 100g of clay contains 3.63g of organic matter.

[0066] Step 2. Extraction and separation of soil...

Embodiment 2

[0080] Step 1. Soil sample pretreatment

[0081] Same as Step 1 of Example 1.

[0082] Step 2. Extraction and separation of soil microplastics

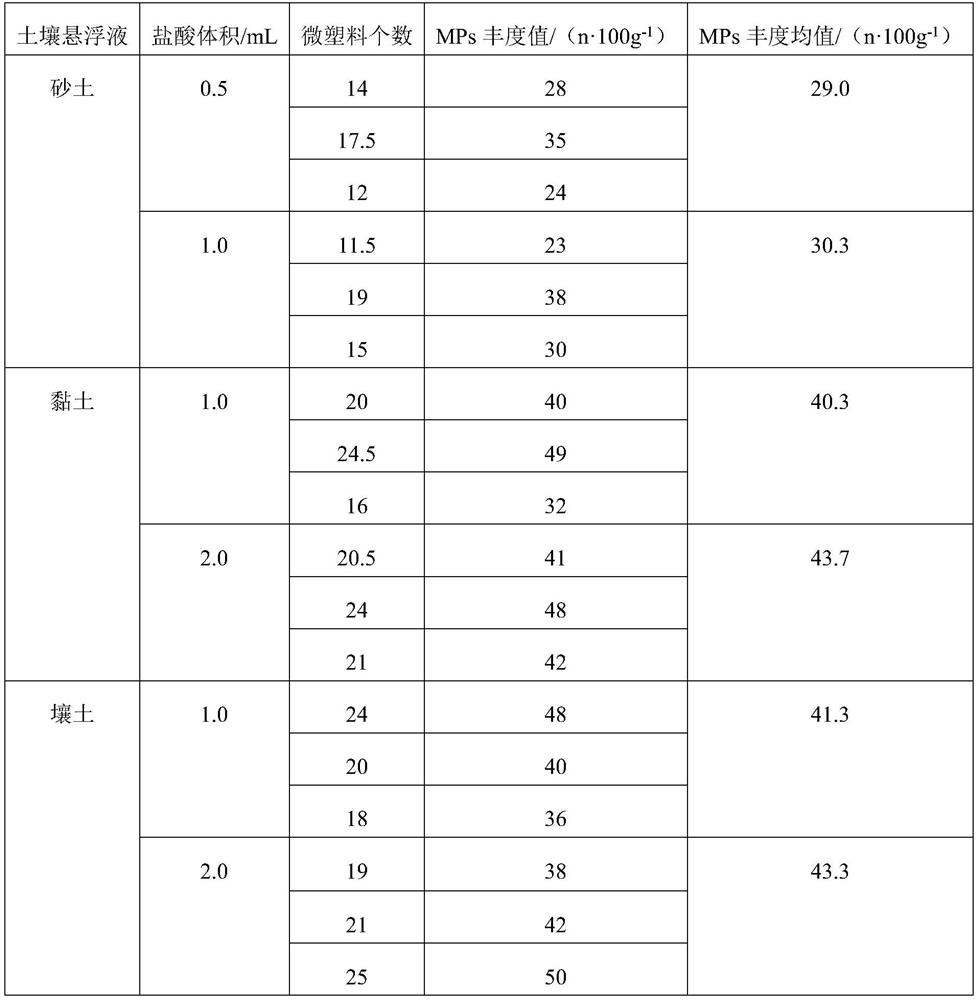

[0083] (1) Put 50.0g of the pretreated soil sample in a 500mL beaker, add saturated ZnCl 2 Aqueous solution 200mL dissolves, makes soil suspension solution, adds hydrochloric acid while stirring, and hydrochloric acid add-on is as follows:

[0084] Add 0.5mL to the sand sample, add 1.0mL to the loam sample, and add 1.0mL to the clay sample.

[0085] Others are the same as in Example 1 and Step 2 (1) is the same.

[0086] (2) Ultrasound and shake for 2 minutes to shake evenly, let stand for stratification, and filter the supernatant after stratification; repeat this step 3 times to obtain samples from which soil microplastics have been extracted.

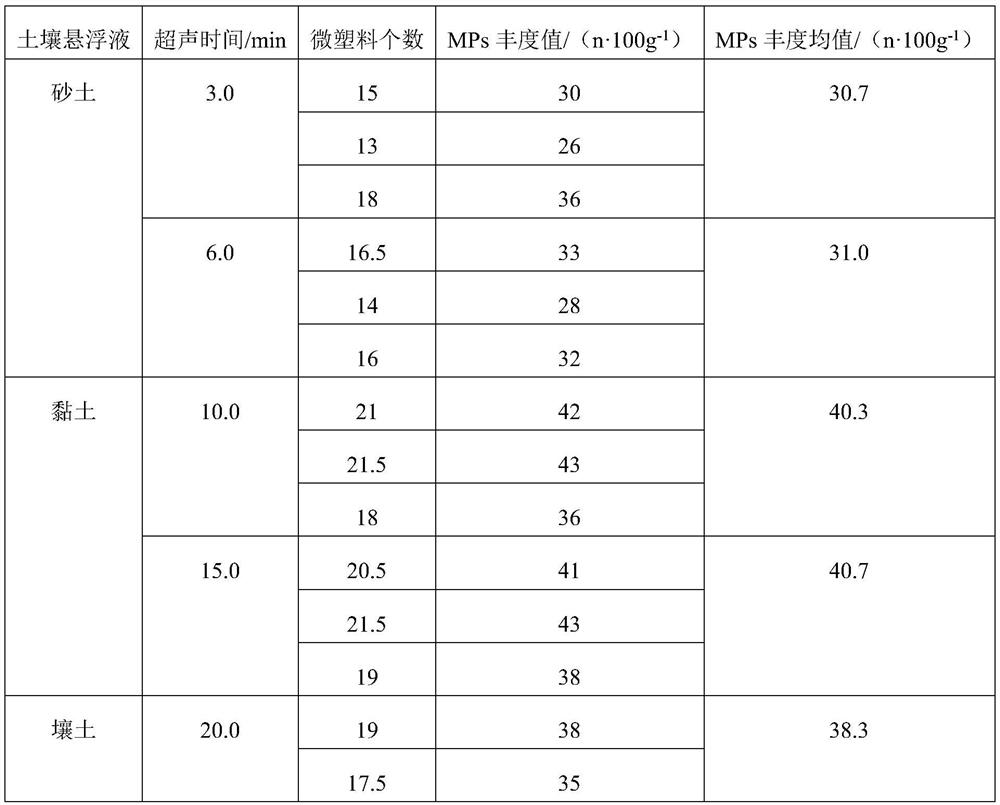

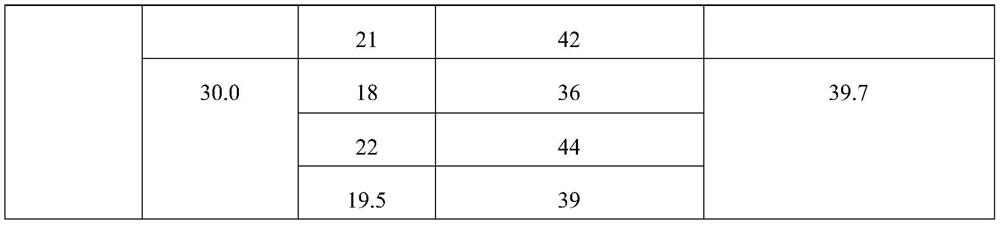

[0087] The ultrasonic power is 600W, and the frequency is 40KHz. The ultrasonic time of sand, clay and loam is shown in Table 2.

[0088] Static layering time, the static layering time ...

Embodiment 3

[0095] Step 1. Soil sample pretreatment

[0096] Same as Step 1 of Example 1.

[0097] Step 2. Extraction and separation of soil microplastics

[0098] (1) with embodiment 2 step two (1);

[0099] (2) With embodiment 1 step two (1).

[0100] Step 3. Purification of microplastics

[0101] Into samples from which soil microplastics were extracted:

[0102] Sandy soil: add 2mol / L FeSO 4 Solution 2mL and mass fraction of 30% H2 o 2 Solution 5mL (as shown in Table 3), H 2 o 2 with Fe 2+ The molar ratio is 10:1, the H in the hydrogen peroxide solution 2 o 2 With the mass ratio between described organic matter is 5:1;

[0103] Add 2mol / L FeSO 4 Solution 3mL and mass fraction of 30% H 2 o 2 Solution 10mL (as shown in Table 3), H 2 o 2 with Fe 2+ The molar ratio is 15:1, the H in the hydrogen peroxide solution 2 o 2 The mass ratio with the organic matter is 10:1;

[0104] Clay: add 2mol / L FeSO 4 Solution 13mL and mass fraction of 30% H 2 o 2 Solution 30mL (as sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com