Composite, and structure and thermistor using same

A thermistor and composite technology, applied in the composite field, can solve problems such as thermal expansion coefficient cracks, interface peeling, etc., and achieve the effects of small resistivity change, high bonding strength, and electrical characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

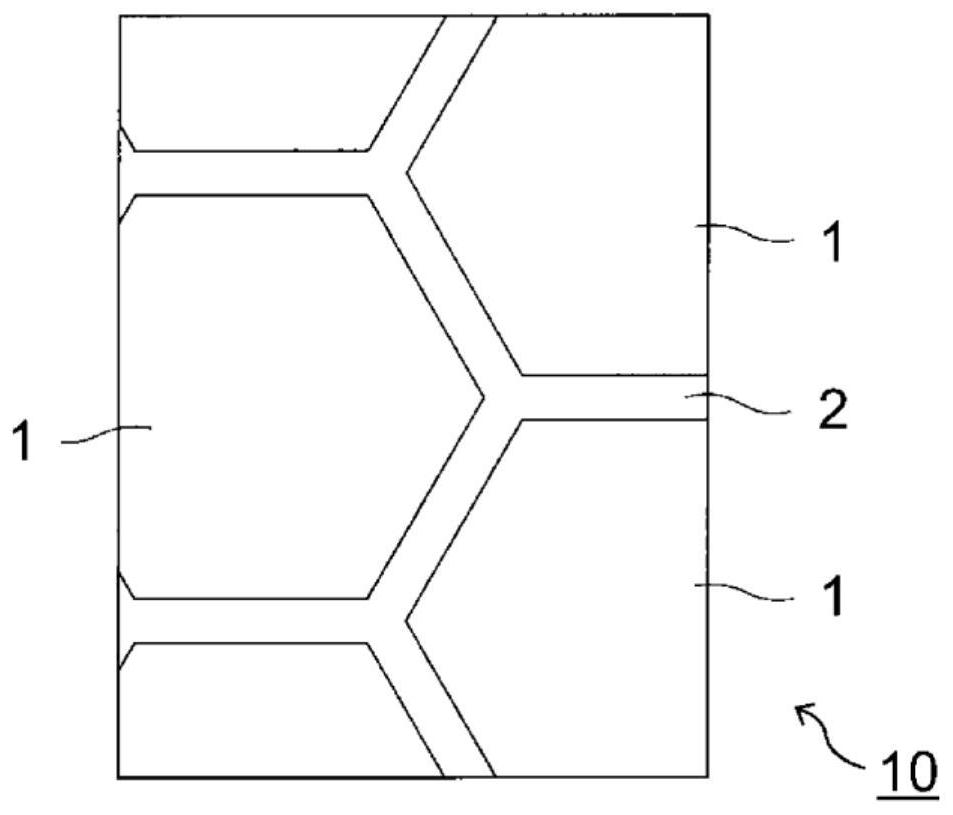

[0064] like figure 1 As shown, the complex (composite of metal oxide) 10 of the present embodiment includes:

[0065] A plurality of first particles (hereinafter also referred to as "metal oxide particles") 1, consisting of metal oxides comprising at least one first metal element, and

[0066] The first amorphous phase 2 exists in a plurality of first particles.

[0067] The metal oxide constituting the metal oxide particles 1 serves as the first metal element comprising at least one of Mn and Ni, and may further comprise at least one selected from the group consisting of Fe, Al, Co, and Cu. MN and / or NI are essential metal elements of metal oxides. Further, at least one of Fe, Al, Co, and Cu is selected to add metal elements for metal oxides. Any addition of the metal element is preferably at least one selected from the group consisting of Fe, Al and CO. The metal oxide can be a metal oxide semiconductor, in particular a spinel type structure, but is not limited thereto.

[006...

Embodiment approach 2

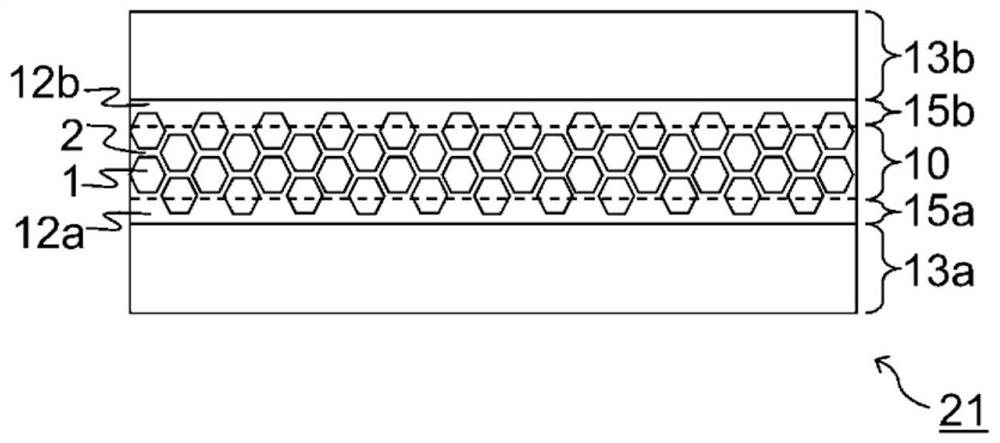

[0128] The present embodiment is obtained by changing the above-described complex, structural and thermistor described in Embodiment 1, as long as it is not particularly described, the same description thereof is applied to the first embodiment.

[0129] like Figure 10 (A), the complex 11 of the present embodiment includes:

[0130] A plurality of first particles (ie, the above "metal oxide particles") 1, consisting of a metal oxide comprising at least one first metal element,

[0131] The first amorphous phase 2 contains the same metal elements as the first metal element, and

[0132] A plurality of second particles (hereinafter, referred to as "resin particles") 3 is also formed by the first resin;

[0133] The first amorphous phase 2 is present between the plurality of metal oxide particles 1 and the plurality of resin particles 3.

[0134] The first resin constituting the resin particles 3 is preferably a resin that is not easily melted by heat, for example, can comprise a pol...

Embodiment 1

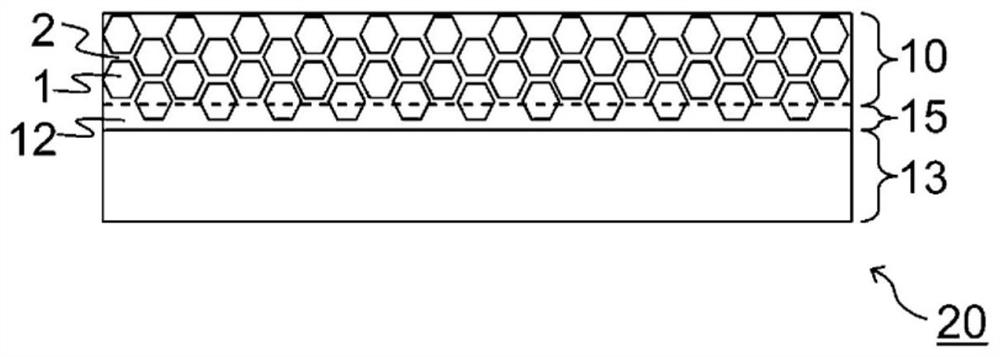

[0159] This embodiment relates to the reference in the first embodiment image 3 Description of the structure.

[0160] To the proportion of Mn: Ni: Al: Al: Al: Al: Al: Al: 1 (atomic ratio) is added to a proportion of 10% by mass (relative to the total mass of metal oxide particles). Acetyl. Acetone manganese, the ethanol is prepared as a solvent, mixed for 16 hours. A material mixture of the form obtained by the thickness of 10 μm is supplied by a blade method on a sheet having a thickness of 30 μm. After drying at 100 ° C for 10 hours, heating the press was heated at 150 ° C for 30 minutes at 100 MPa pressurization. Thereafter, other copper foils (upper electrodes) of the thickness of 30 μm are superimposed on the film from the film from the film (the composite layer containing the metal oxide), and the heating press is used again, heating at 250 ° C for 30 minutes under pressure of 100 MPa. To obtain the precursor structure. The precursor structure was annealed at 250 ° C for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com