Liraglutide composition and application thereof

A technology of liraglutide and polypeptide composition, which can be applied in the directions of drug combination, peptide/protein component, anhydride/acid/halide active ingredient, etc., and can solve the problems of inconvenient administration and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

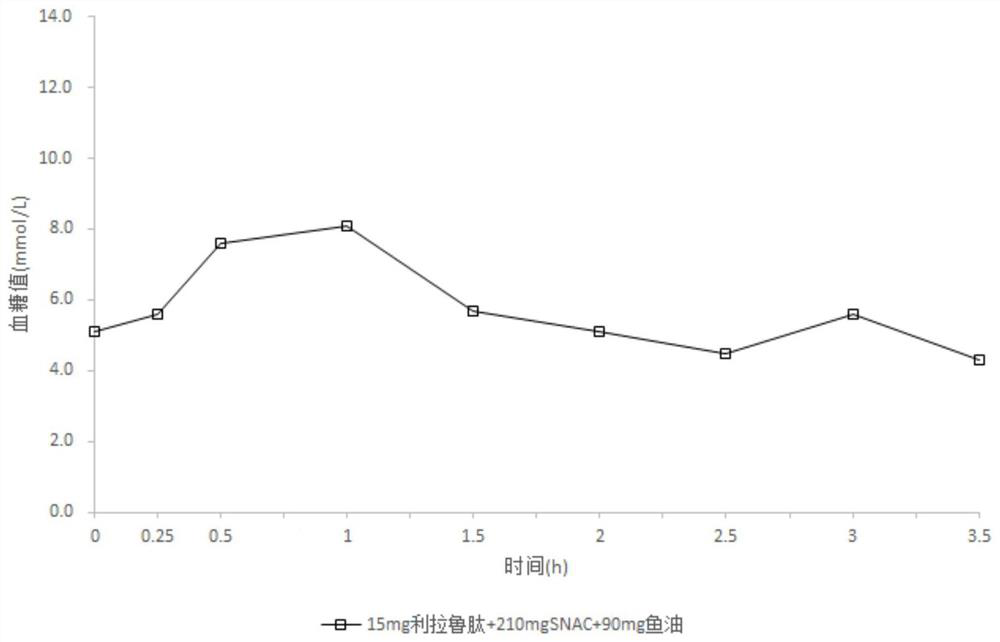

[0072] Composition A

[0073] Liraglutide 15mg Sodium N-(8-(2-hydroxybenzoyl)amino)octanoate 210mg fish oil 90mg

[0074] Preparation

[0075] Mix 15mg of liraglutide, 210mg of sodium N-(8-(2-hydroxybenzoyl)amino) octanoate, and 90mg of fish oil, put it into a capsule, and coat it. Weigh Eudragit L30D, talcum powder, and polyethylene glycol, dissolve with dichloromethane and isopropanol to obtain a coating solution, and spray the coating solution on the surface of the capsule to obtain an enteric-coated capsule. The flow rate of the coating solution is 0.5ml / min, the coating temperature is 30°C-40°C, and the coating weight gain is 7%.

Embodiment 2

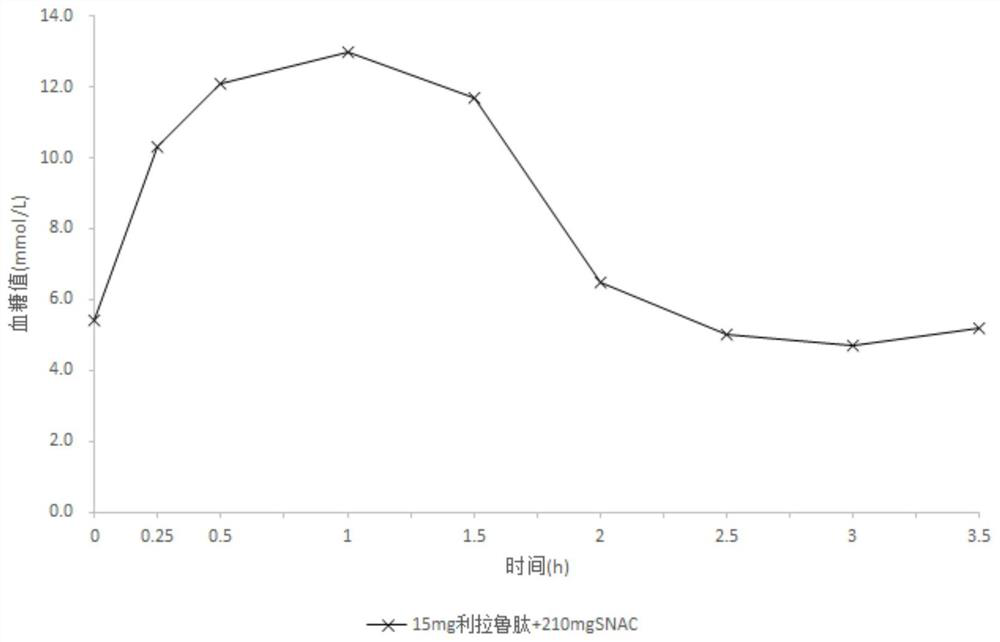

[0077] Composition B

[0078] Liraglutide 15mg Sodium N-(8-(2-hydroxybenzoyl)amino)octanoate 210mg fish oil 0mg

[0079] Preparation

[0080] Mix 15 mg of liraglutide and 210 mg of sodium N-(8-(2-hydroxybenzoyl)amino) caprylate, put it into a capsule, and coat it. Weigh Eudragit L30D, talcum powder, and polyethylene glycol, dissolve with dichloromethane and isopropanol to obtain a coating solution, and spray the coating solution on the surface of the capsule to obtain an enteric-coated capsule. The flow rate of the coating solution is 0.5ml / min, the coating temperature is 30°C-40°C, and the coating weight gain is 7%.

Embodiment 3

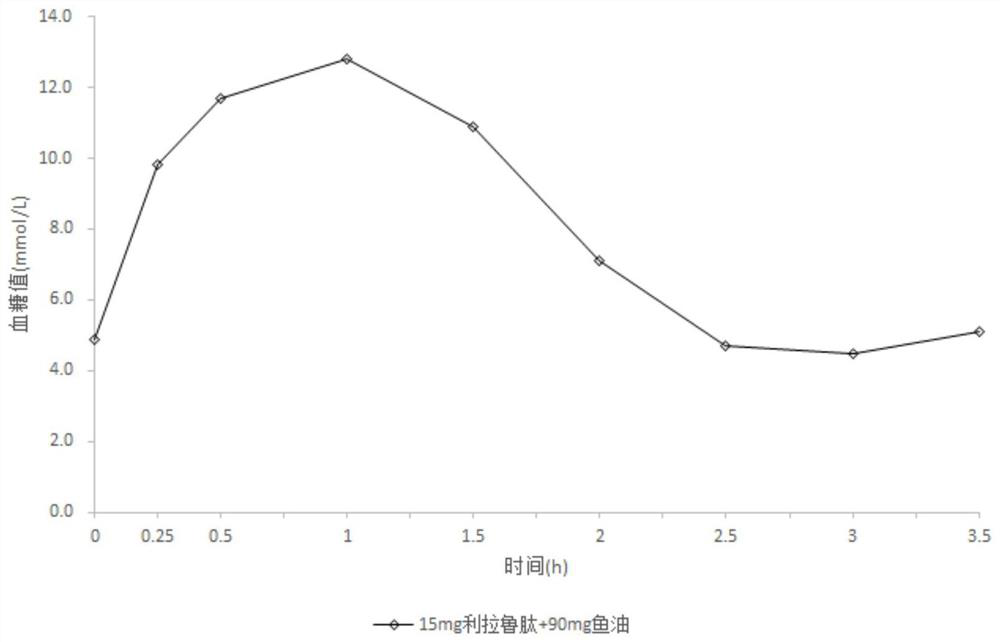

[0082] Composition C

[0083] Liraglutide 15mg Sodium N-(8-(2-hydroxybenzoyl)amino)octanoate 0mg fish oil 90mg

[0084] Preparation

[0085] Mix 15mg liraglutide and 90mg fish oil, put it into a capsule, and coat it. Weigh Eudragit L30D, talcum powder, and polyethylene glycol, dissolve with dichloromethane and isopropanol to obtain a coating solution, and spray the coating solution on the surface of the capsule to obtain an enteric-coated capsule. The flow rate of the coating solution is 0.5ml / min, the coating temperature is 30°C-40°C, and the coating weight gain is 7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com