Radiotherapy sensitization material based on porous iron-based MOF structure and preparation method and application thereof

A porous iron and iron-based technology, applied in the field of nano-biomedicine, can solve the problems of poor biocompatibility, limited application, biological damage, etc., and achieve the effects of good stability, simple preparation process, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

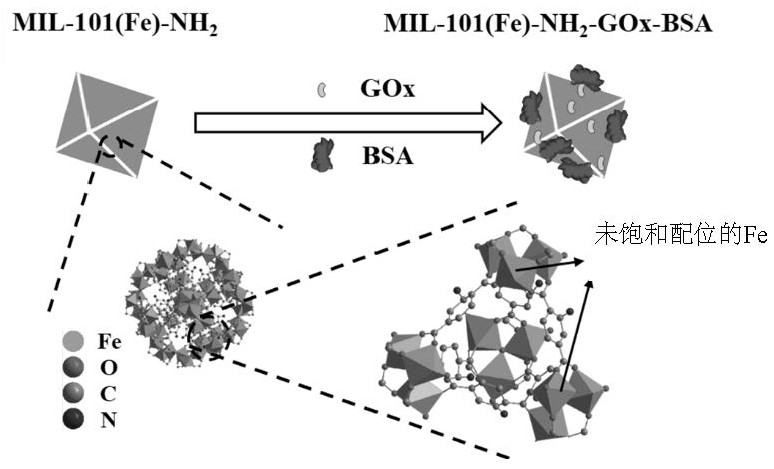

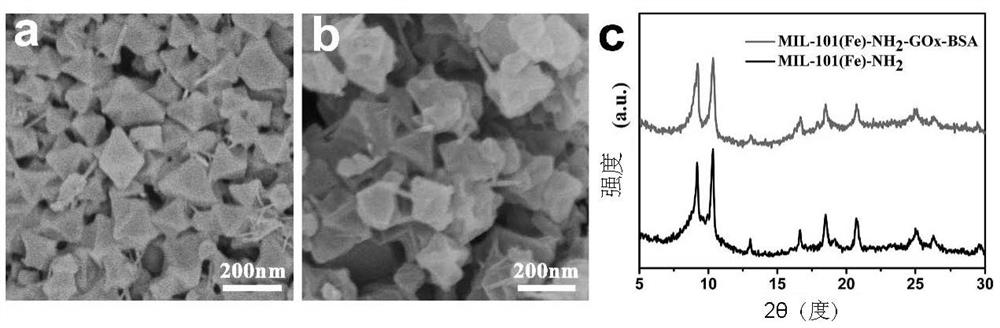

[0048] MIL-101(Fe)-NH 2 Preparation of nanoparticles:

[0049] 0.675g FeCl 3 ·6H 2 O (0.0025mol) and 0.226g 2-aminoterephthalic acid (0.00125mol) were successively loaded into the reaction kettle (lined with polytetrafluoroethylene), and 15mL N,N-dimethylformamide (DMF) was quickly added to In the above-mentioned reaction kettle, seal it after stirring evenly, and react at 110° C. for 24 hours. After the reaction, the product was collected by centrifugation, and the product was washed three times with ethanol and deionized water respectively, and then the washed product was placed in an oven at 40°C for 10 h to obtain the prepared MIL-101(Fe)-NH 2 . MIL-101(Fe)-NH 2 The particle size of the nanoparticles is 80-300nm.

Embodiment 2

[0051] (1) MIL-101(Fe)-NH 2 Preparation of nanoparticles:

[0052] 1.01g Fe(NO 3 )·9H 2 O and 0.226g 2-aminoterephthalic acid are successively loaded into the reaction kettle (polytetrafluoroethylene lining), and 20, 25, and 30mL N,N-dimethylformamide (DMF) are quickly added to the above reaction kettle respectively. , stir evenly and then seal it, and react at 110°C for 24h. After the reaction, the product was collected by centrifugation, and the product was washed three times with ethanol and deionized water respectively, and then the washed product was placed in an oven at 40°C for 10 h to obtain the prepared MIL-101(Fe)-NH 2 . MIL-101(Fe)-NH 2 The size range of the nanoparticles is 80-300nm.

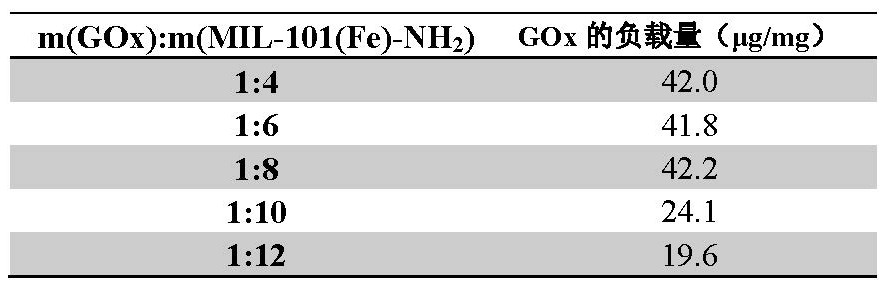

[0053] (2) Radiosensitizing material MIL-101(Fe)-NH based on porous iron-based MOF structure 2 - Preparation of GOx-BSA nanoparticles:

[0054] 0.040g MIL-101(Fe)-NH 2 and 5 mg of GOx were added to 25 mL of water for three times, stirred evenly, added 0.050 g of BSA, stirred...

Embodiment 3

[0057] MIL-101(Fe)-NH 2 - Preparation of BSA:

[0058] Get the synthetic MIL-101(Fe)-NH in embodiment 1 2 Nanoparticles 0.040g, dispersed in 25mL of tertiary water, stirred evenly, added 0.050g BSA, stirred for 24h, centrifuged to collect the product, freeze-dried to obtain MIL-101(Fe)-NH 2 -BSA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com