Papermaking coating and preparation method thereof

A coating and raw material technology, which is applied in the field of high-strength coatings and preparations for papermaking, can solve the problems of paper lint and powder loss, easy occurrence of paper, lint and powder loss, etc., and achieve increased glass transition temperature, increased strength, and stable coating performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

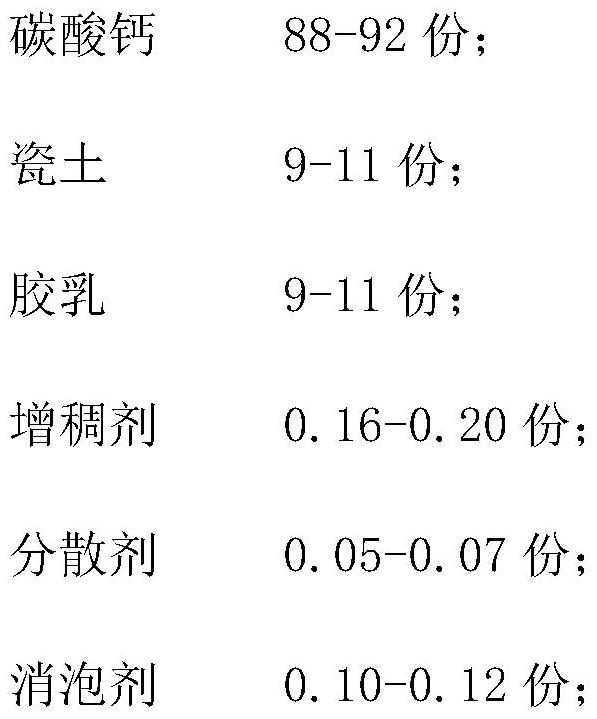

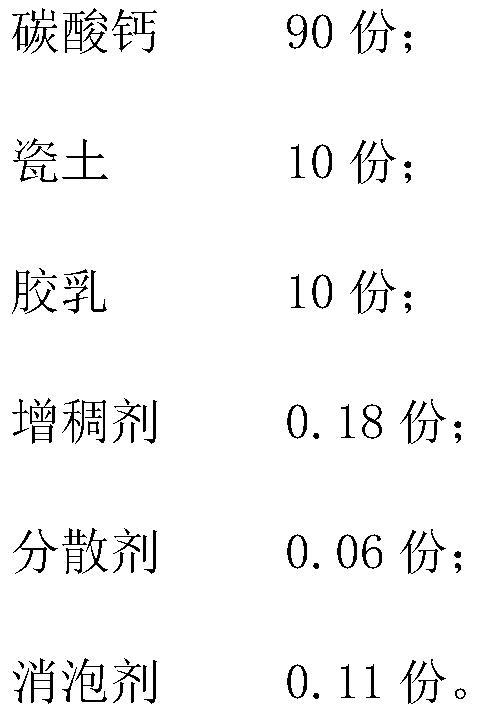

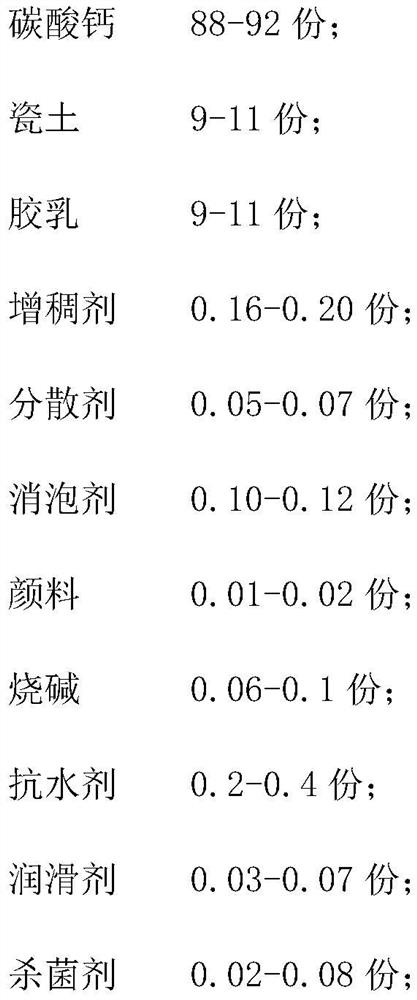

[0014] The present invention is a kind of paint for papermaking, the composition raw material of this paint and the ratio of parts by weight of raw materials are:

[0015]

[0016] Described calcium carbonate is heavy calcium carbonate, and it is used as the main filler in coating.

[0017] The china clay is calcined china clay, and the present invention does not use starch, but calcined china clay, which can further increase the drying temperature after coating.

[0018] The latex is styrene-butadiene latex, the main component of which is styrene-butadiene. Since the styrene-butadiene latex has high strength and does not form precipitation, the strength of the coating can be improved. At the same time, styrene-butadiene latex is suitable for an environment with a pH of 6-10, and its chemical properties are stable. The pH of the paint can be properly adjusted by caustic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com