Air cushion heat insulation anti-convection layer and preparation method thereof

A troposphere and air cushion technology, applied in heat exchange equipment, chemical instruments and methods, and protection of pipelines through thermal insulation, etc., can solve the problems of imperfect technological process, inconvenient construction, and inconspicuous effect of air cushion thermal insulation against troposphere thermal insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

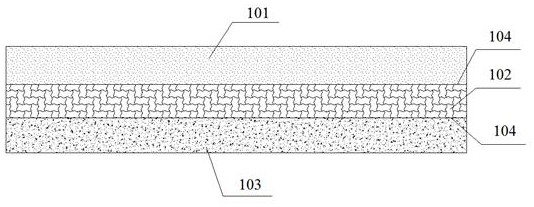

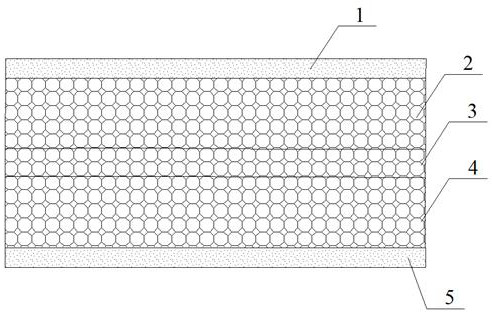

[0050] Such as Figure 1-8 Shown, a kind of air cushion heat insulation anti-drain layer, comprises from inside to outside including aluminum foil reflective layer I1, polyethylene air bubble film layer I2, polyethylene air bubble film layer II3, polyethylene air bubble film layer III4 and aluminum foil reflective layer II5; Both the aluminum foil reflective layer I1 and the aluminum foil reflective layer II5 are aluminum foil reflective layers, and the aluminum foil reflective layer is successively aluminum foil 101, polyethylene terephthalate film 102 and chlorinated polyethylene film 103 from outside to inside; The aluminum foil 101 and the polyethylene terephthalate film 102 , and the polyethylene terephthalate film 102 and the chlorinated polyethylene film 103 are bonded by a flame retardant adhesive layer 104 .

[0051] The thickness of the aluminum foil 101 is 6.5-7 μm, the thickness of the polyethylene terephthalate film 102 is 12 μm, the thickness of the chlorinated p...

Embodiment 2

[0055] A method for preparing an air cushion heat-insulating anti-draft layer, comprising the following steps:

[0056] S1. Preparation of aluminum foil reflective layer:

[0057] S101, dispensing glue: the mass concentration ratio of polyurethane glue and solvent ethyl acetate is 1:1.5, first pour the polyurethane glue into the glue dispensing bucket 9, and then add the ethyl acetate solvent while stirring to dilute;

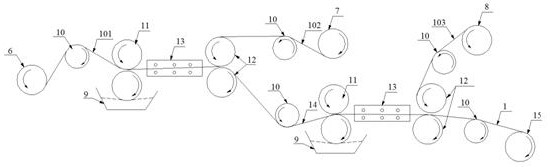

[0058] S102, roll-up film penetration: put the aluminum foil 101 to be glued, the polyethylene terephthalate film 102 and the chlorinated polyethylene film 103 on the unwinding reel I6, unwinding reel II7 and unwinding reel III8 respectively, adjust The tension of each unwinding shaft ensures that aluminum foil 101, polyethylene terephthalate film 102 and chlorinated polyethylene film 103 are released stably and evenly by guide roller 10;

[0059] S103. Gluing: adjust the air pressure of the rotating arm of the compound machine, the air pressure of the scraper...

Embodiment 3

[0080] Example 3, such as Figure 9 As shown, that is, the structure of the aluminum foil reflective layer I1 or the aluminum foil reflective layer II5 in the prior art, the aluminum foil reflective layer I1 or the aluminum foil reflective layer II5 are successively polyethylene terephthalate film 102, aluminum foil 101. Chlorinated polyethylene film 103, the measured thermal conductivity of the aluminum foil reflective layer I1 or aluminum foil reflective layer II5 is 0.0407 W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com