Combustion catalyst screening device and method based on nitrocotton stability

A combustion catalyst and nitrocellulose safety technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large man-made errors, cumbersome operation steps, cumbersome iodometric method and other problems of the test paper method, and achieve quantitative detection of NO2 content, operation Simple steps and reliable screening results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] From the two combustion catalysts of carbon black and copper oxide, the combustion catalyst which is more suitable for the nitrocellulose-based solid propellant is screened out in terms of ensuring the chemical stability of the nitrocellulose. The used nitrocellulose has a nitrogen content of 11.75% to 12.10%, a fineness of 65mL to 75mL, and carbon black and copper oxide in powder form.

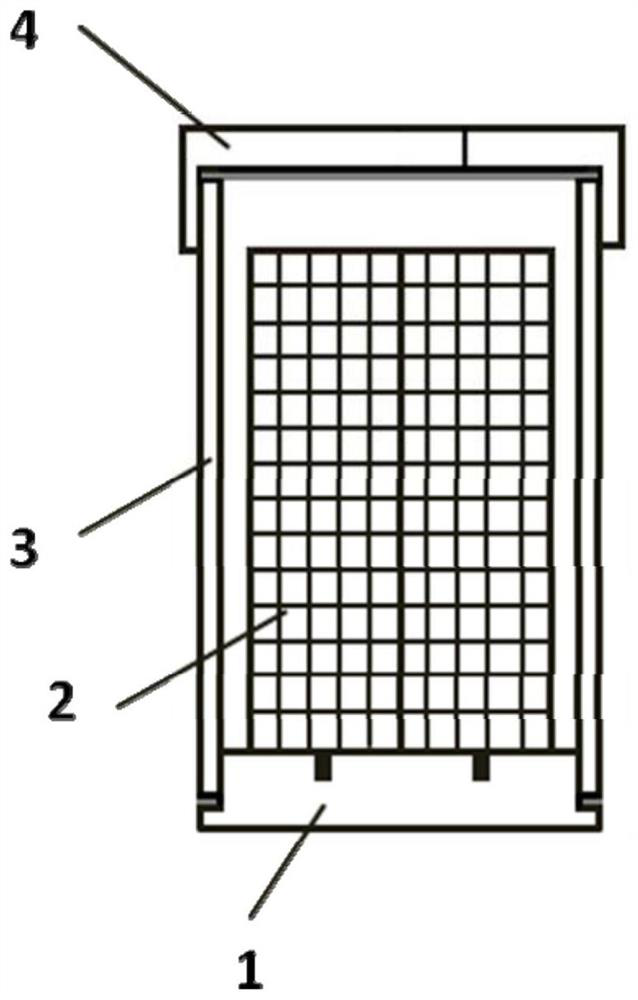

[0071] Such as figure 1 Shown, a kind of screening device and method of the combustion catalyst based on the stability of nitrocellulose, described device comprises sample tank, airtight needle, oven, gas chromatograph, it is characterized in that, described sample tank comprises base 1, spacer 2. Can body 3, cap 4;

[0072]The base 1 is a revolving body, the base 1 is composed of upper and lower parts, the lower part of the base 1 is a base plate, the upper part of the base 1 is a first fixed plate, the upper surface of the base plate is connected with the lower surface of the first ...

Embodiment 2

[0092] Two combustion catalysts, one is carbon black and the other is Al / Fe 2 o 3 The mixture adopts the screening device and method designed in this patent to screen out the combustion catalyst that is more suitable for the nitrocellulose-based solid propellant in terms of ensuring the chemical stability of the nitrocellulose. The nitrogen content of the nitrocellulose used is 11.75%~12.10%, the fineness is 65mL~75mL, carbon black, Al / Fe 2 o 3 The mixture is in powder form.

[0093] A screening device for a combustion catalyst based on the stability of nitrocellulose includes a sample tank, an airtight needle, an oven, and a gas chromatograph, and is characterized in that the sample tank includes a base 1, a partition 2, a tank body 3, and a cap 4;

[0094] The base 1 is a revolving body, the base 1 is composed of upper and lower parts, the lower part of the base 1 is a base plate, the upper part of the base 1 is a first fixed plate, the upper surface of the base plate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com