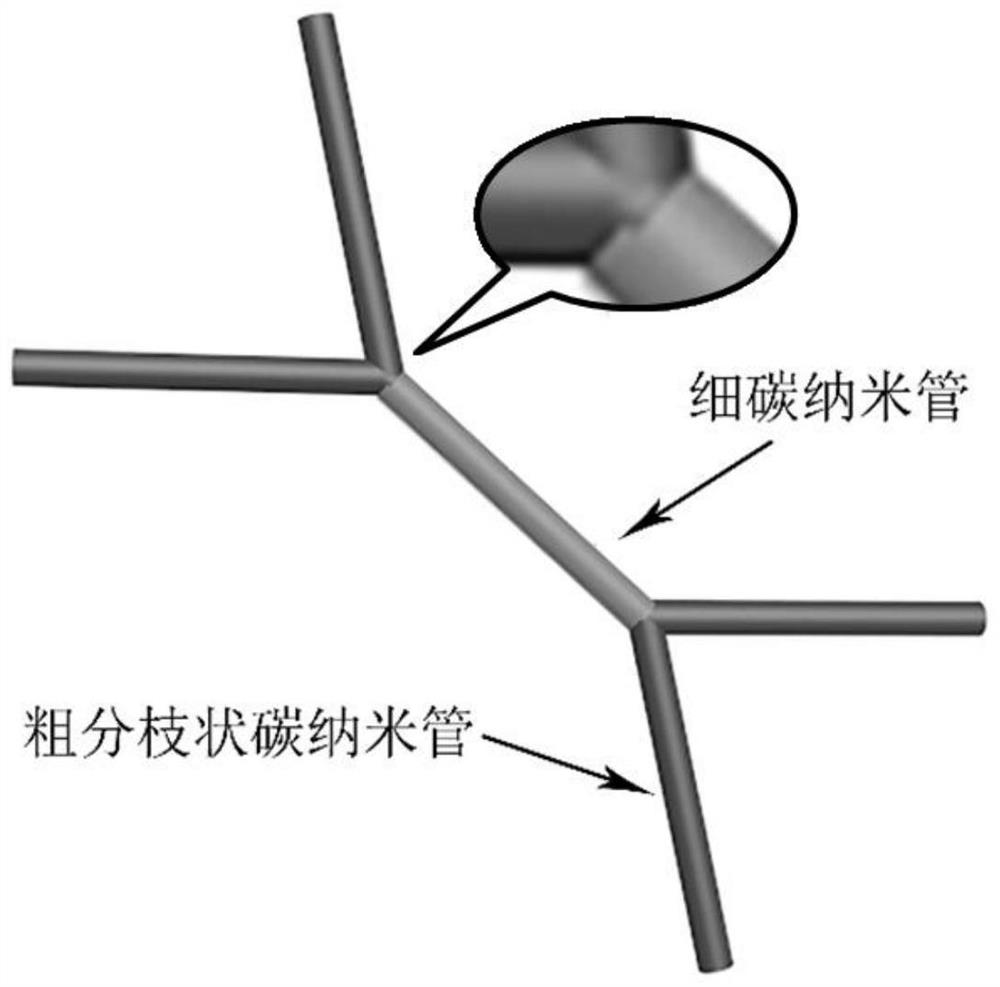

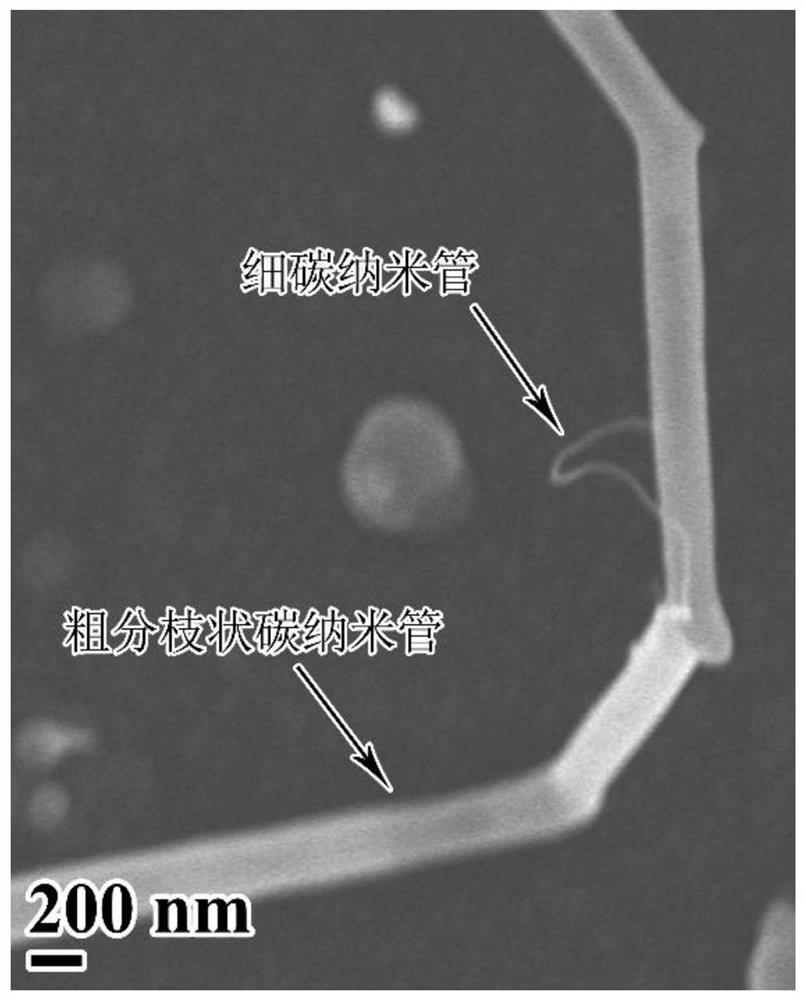

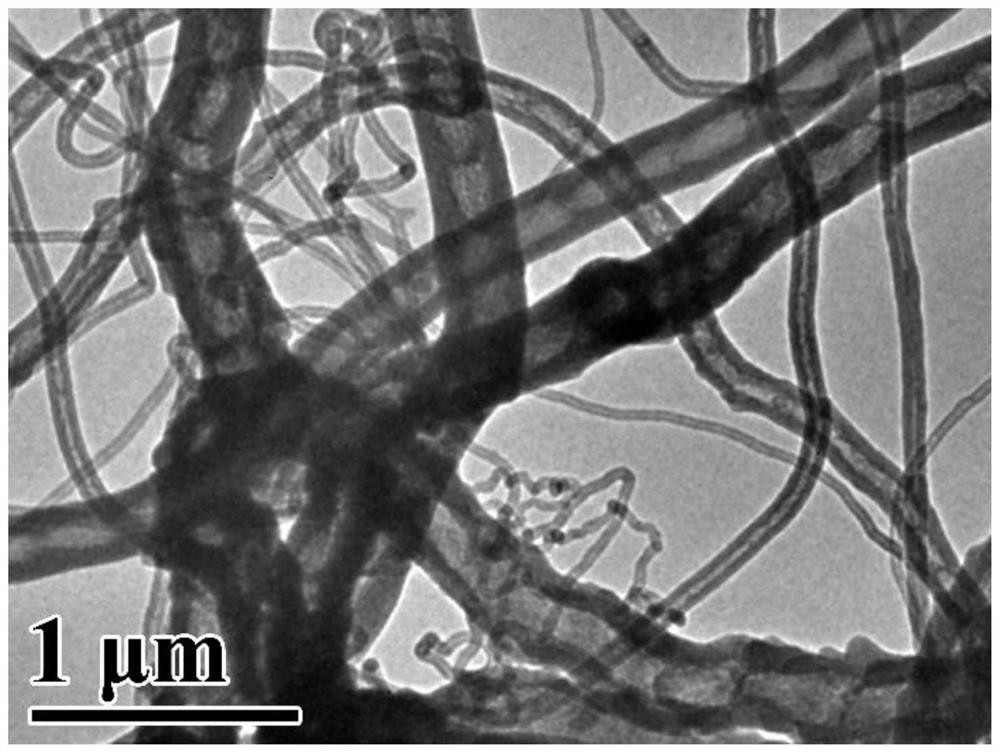

Carbon nanotube composite material with hierarchical structure and preparation method thereof

A carbon nanotube and hierarchical structure technology, applied in the field of carbon nanotube composite materials with hierarchical structure and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A carbon nanotube composite material with a hierarchical structure and a preparation method thereof, the steps are as follows:

[0043] Step 1: Preparation of Catalyst

[0044] Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolved in deionized water, making the Ni 2+ and Mg 2+ The sum of the concentrations is 0.2mol / L, then add 2.5mol / L sodium hydroxide solution to obtain a mixed solution, the volume ratio of sodium hydroxide solution and deionized water is 1:4, and then reflux the mixed solution at 95°C for 12h , and then filtered, the filtered product was washed with deionized water and freeze-dried, the product was separated in air, calcined at 600 °C for 2 h, and then in H 2 Continue calcination at the same temperature for 35 min under a mixed atmosphere with Ar to obtain a Ni nanoparticle product supported by MgO as a substrate, which is a Ni / MgO catalyst, and the H 2 The gas flows of Ar and Ar are 100mL / min and 300~330mL / min respectively, and the H 2 The flow rate of Ar a...

Embodiment 2

[0062] A carbon nanotube composite material with a hierarchical structure and a preparation method thereof, the steps are as follows:

[0063] Step 1: Preparation of Catalyst

[0064] Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolved in deionized water, making the Ni 2+ and Mg 2+ The sum of the concentrations is 0.2mol / L, then add 2.5mol / L sodium hydroxide solution to obtain a mixed solution, the volume ratio of sodium hydroxide solution and deionized water is 1:4, and then reflux the mixed solution at 95°C for 12h , and then filtered, the filtered product was washed with deionized water and freeze-dried, the product was separated in air, calcined at 620 °C for 2 h, and then heated in H 2 Continue calcination at the same temperature for 40 min under a mixed atmosphere with Ar to obtain a Ni nanoparticle product supported by MgO as a substrate, which is a Ni / MgO catalyst, and the H 2 The gas flows of Ar and Ar are 110mL / min and 330mL / min respectively;

[0065] Step 2: Preparation o...

Embodiment 3

[0070] A carbon nanotube composite material with a hierarchical structure and a preparation method thereof, the steps are as follows:

[0071] Step 1: Preparation of Catalyst

[0072] Ni(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolved in deionized water, making the Ni 2+ and Mg 2+ The sum of the concentrations is 0.2mol / L, then add 2.5mol / L sodium hydroxide solution to obtain a mixed solution, the volume ratio of sodium hydroxide solution and deionized water is 1:4, and then reflux the mixed solution at 95°C for 12h , and then filtered, the filtered product was washed with deionized water and freeze-dried, the product was separated in air, calcined at 600 °C for 2 h, and then in H 2 Continue calcination at the same temperature for 30 min under a mixed atmosphere with Ar to obtain a Ni nanoparticle product supported by MgO as a substrate, which is a Ni / MgO catalyst, and the H 2 The flow rates of Ar and Ar are 120mL / min and 360mL / min respectively;

[0073] Step 2: Preparation of Hier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com