TPU protective film, and TPU base film and preparation method thereof

A technology of protective film and base film, applied in the direction of film/flake adhesive, coating, adhesive, etc., can solve the problems of serious warpage, limited hardness by process, easy cracking, etc., to broaden application scenarios and fields , The process is simple and controllable, and the liquid flow is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

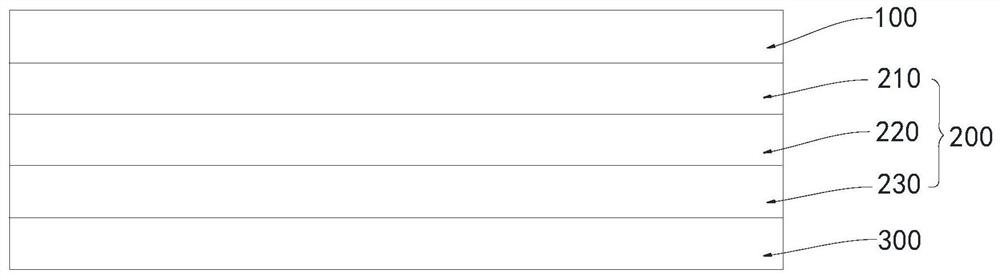

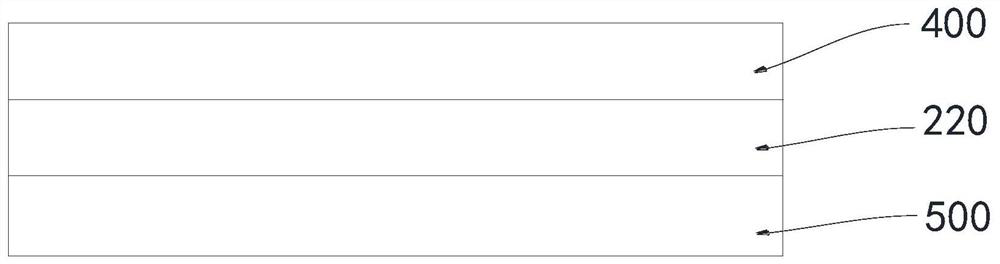

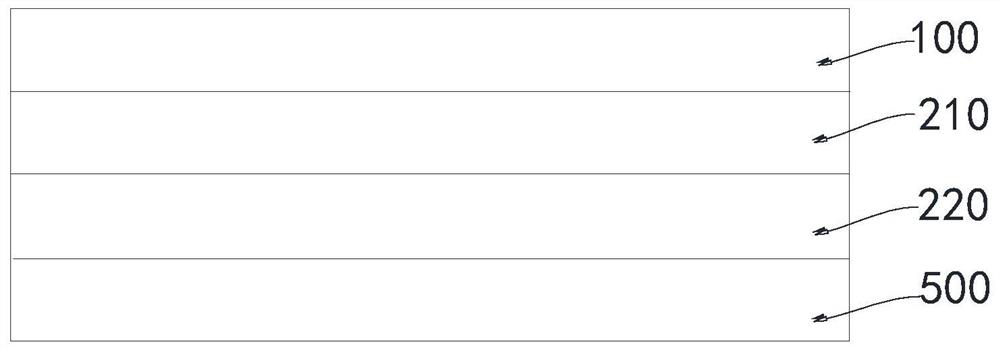

[0051] A method of preparing a TPU protective film, which includes the steps of:

[0052] Step 1: Mounting a 50 um silicone oil exemplary film 400, release force 10GF; platen binding is 60 um low-viscous silica protective film 500, silica gel peeling force 3GF; the dissolved TPU solution screw meter Pumping into the slit head, filtering the core specification 10 um, using a slit coating method to coating the TPU solution in silicone oil 400, TPU solution comprises 30 parts of TPU elastic rubber particles (hardness 88A) 4.5-parts of the chain extender, 13 parts of isocyanate curing agent, 0.5 parts of the leveling agent, 40 parts of butanone, 30 parts of ethyl acetate, 5 parts of the Hwhenecanone; the TPU solution is 35.9%, viscosity 850cp, the narrow When the spray is applied, the line speed is 4m / min, the welding pump speed is 32 rpm, and the oven drying is solidified, the temperature is arranged to be the first section 50 ° C, the second section 80 ° C, the third section 120 °...

Embodiment 2

[0056] A method of preparing a TPU protective film, which includes the steps of:

[0057] Step 1: Volume 1 is 50 um thick silicon oil separated film 400, release force 8GF; platen binding is 60 um low-viscous silica protective film 500, silica gel viscosity 2.5GF; screw for dissolved TPU solution The pumping pump is pumped into a slit head, and the filter core specification is 10um, and the TPU solution is applied in the release film in a slit coating method; the TPU solution includes 28 parts of TPU elastic rubber particles (hardness 98a), 3 parts of the chain extender, 8 part isocyanate curing agents, 0.5 parts of the leveling agent, 50 parts of butanone, 20 parts of ethyl acetate, 6 partial cyclohexanone; TPU solution solid content 32.1%, viscosity 730CPS; slit coating When the line speed is 5m / min, the welding pump speed is 35 rpm, and the oven drying is solidified, the temperature is arranged to be the first section 50 ° C, the second section 80 ° C, the third section 120 °...

Embodiment 3

[0061]Step 1: Volume 1 is 50 um thick silicon oil separated film 400, release force 10GF; platen binding is 60 um low adhesive silica protective film, silica gel viscosity 3GF; a solution of TPU solution to dissolve with screw metering pump Pumping to the slit coating head, filtering the core specification 10 um, using a slit coating method to coating the TPU solution in the silicone oil extension film 400, TPU solution comprises 32 serving of TPU elastic classes (hardness 95a), 3.5 parts of the chain extender, 10 part isocyanate curing agents, 0.5 parts of the leveling agent, 50 parts of ketone, 25 parts of ethyl acetate, 6 parts of cyclohexanone; the TPU solution solid content was 34.2%, viscosity 950 cps. When the slit is coated, the wire speed is 5 m / min, the weld pump speed is 36 rpm, and the oven drying is solidified, the temperature is arranged to be a first section 50 ° C, the second 80 ° C, the third section 120 ° C, Section 4 130 ° C, Section 5 130 ° C, Section 80 ° C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing dosage | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| release force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com