Yak hide glue/PMVE-MA composite material and preparation method and application thereof

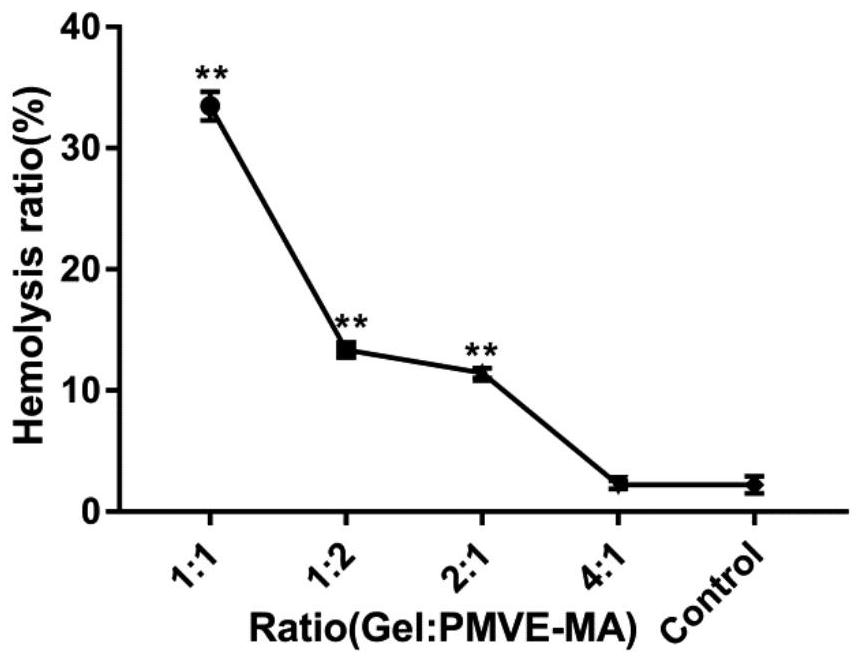

A composite material and yak leather technology, which is applied in the field of yak leather glue/PMVE-MA composite material and its preparation, can solve the problems of resource waste, environmental pollution, and ineffective utilization, and achieve excellent swelling degree and mechanical properties, low The effect of hemolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1, Preparation of Yak Bulp / PMVE-MA Composite Bracket of the Invention

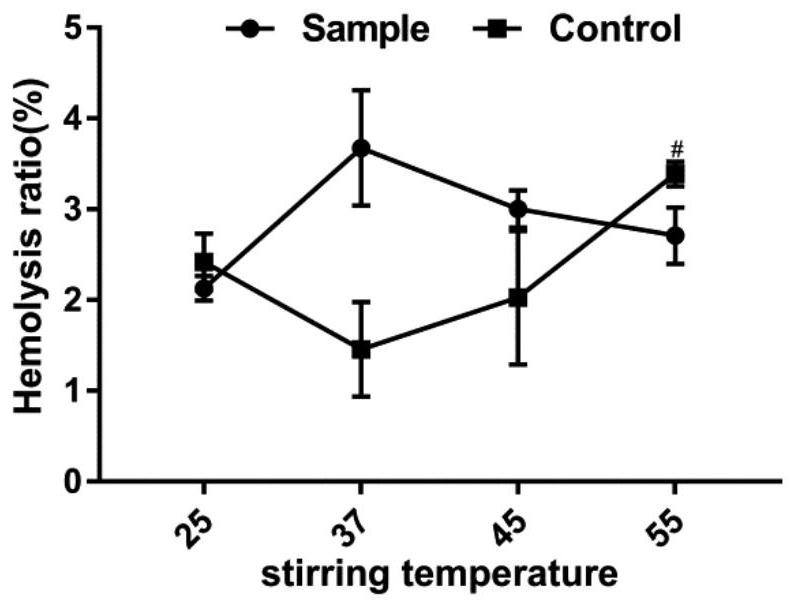

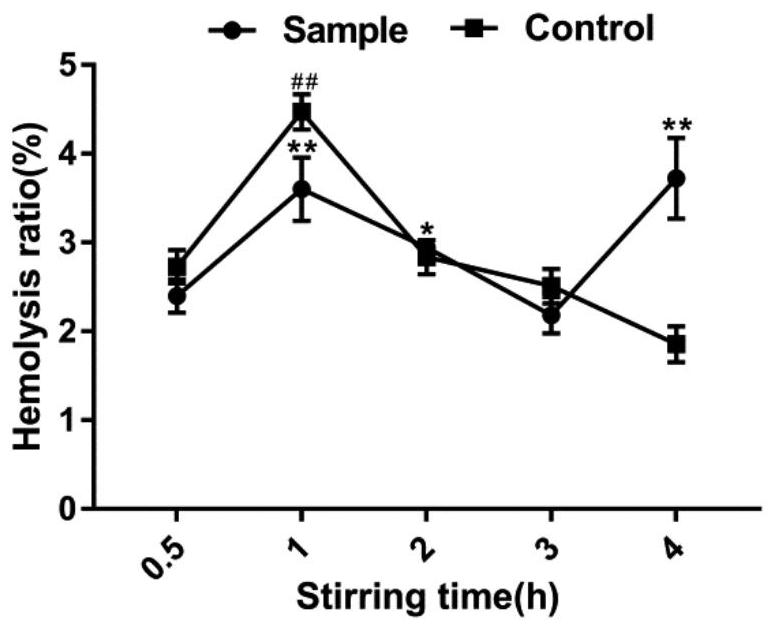

[0040] The formation of yak skin solution (8% w / v) and PMVE-MA solution (1.33% w / v) in 0.5 mol / L acetic acid solution, mixed with 1: 1 ratio (yak leather: PMVE- MA mass ratio 6: 1), magnetic force was stirred at 41 ° C for 3.85 h, and the mixed mixed solution after stirring was poured into a suitable mold, and the freeze-dried, freeze-dried material sample was carried out under -80 ° C for 24 h. 10% HMDI (prepared in isopropyl alcohol) was soaked in a solution for 2 hours, washed twice with isopropyl alcohol, and was naturally widened to be used, and then clean it with pure water three times.

Embodiment 2

[0041] Example 2, Preparation of Yak Bulp / PMVE-MA Composite Bracket of the Invention

[0042]The formulation of yak skin (8% w / v) and PMVE-MA solution (1% w / v) were dissolved with 0.5 mol / L acetic acid solution, and the two solutions were mixed in 1: 1 ratio (yak leather: PMVE- MA mass ratio 8: 1), magnetic force was stirred at 55 ° C for 4 h, and the mixed mixed solution after stirring was poured into a suitable mold, and after crystallizing at -50 ° C for 24 h, crystall dry, freeze-dried material sample in 10 % HMDI (prepared in isopropyl alcohol) was soaked for 3 h after 3 hours, washed twice with isopropyl alcohol, and was naturally widened, and then washed three times with pure water.

Embodiment 3

[0043] Example 3, Preparation of Yak Bulp / PMVE-MA Composite Bracket of the Invention

[0044] The formation of yak skin (8% w / v) and PMVE-MA solution (2% w / v), two solutions were mixed with 0.5 mol / L acetic acid solution, and the two solutions were mixed in 1: 1 ratio (yak leather: PMVE- MA mass ratio 4: 1), magnetic force was stirred at 37 ° C for 1 h, and the mixed solution after stirring was poured into a suitable mold, and after crystallizing at -100 ° C for 24 h, crystall dry, freeze-dried material sample in 10 % HMDI (prepared in isopropyl alcohol) After soaking for 1 h after 1 h, it was cleaned with isopropyl alcohol, and was naturally widened to be used in alcohol, and then washed three times with pure water.

[0045] The beneficial effects of the composite materials of the present invention are demonstrated by experimental examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com