Ultrasonic cleaning agent and preparation method thereof

A cleaning agent and ultrasonic technology, applied in the field of ultrasonic cleaning agent and its preparation, achieves the effects of good biodegradability, high stability and strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

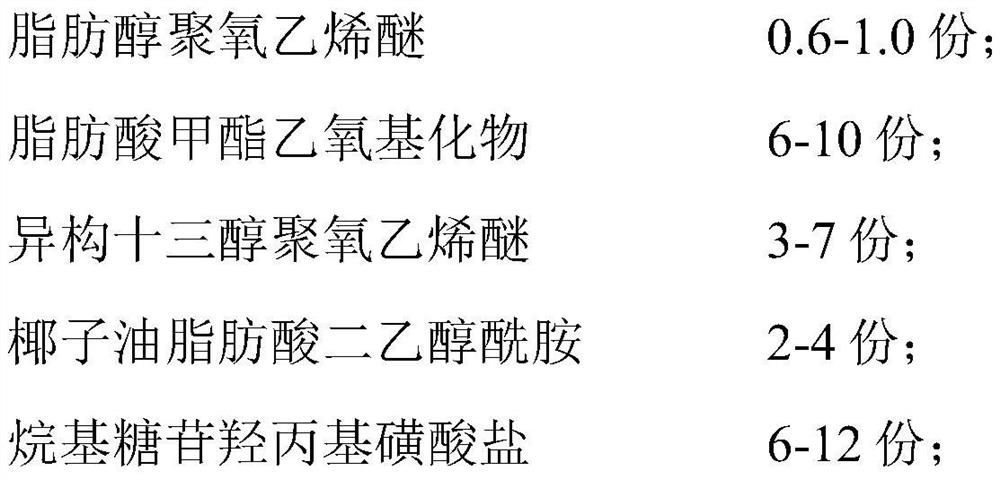

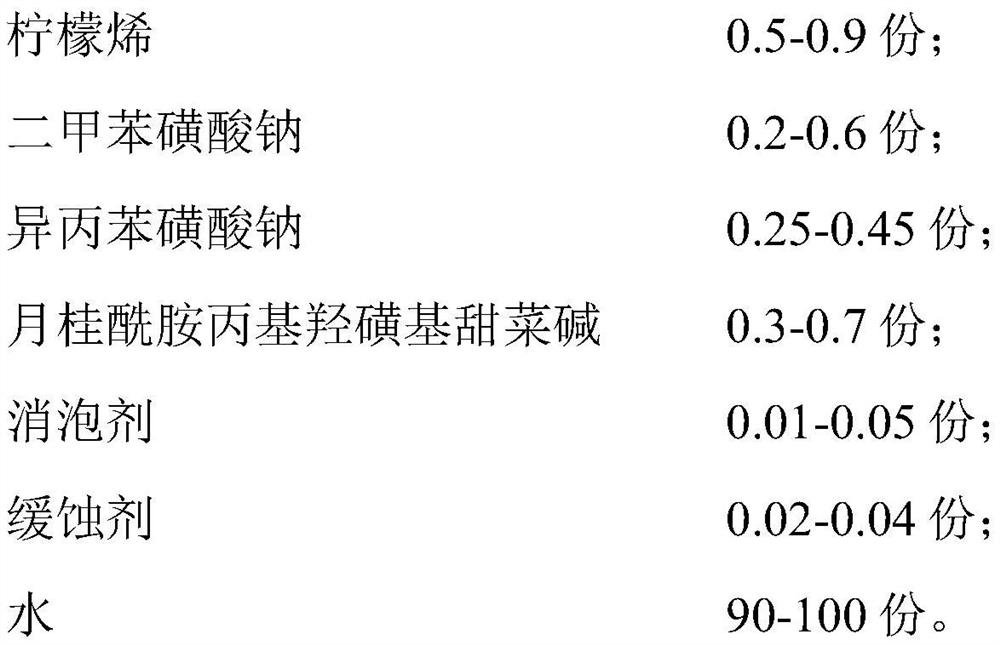

Method used

Image

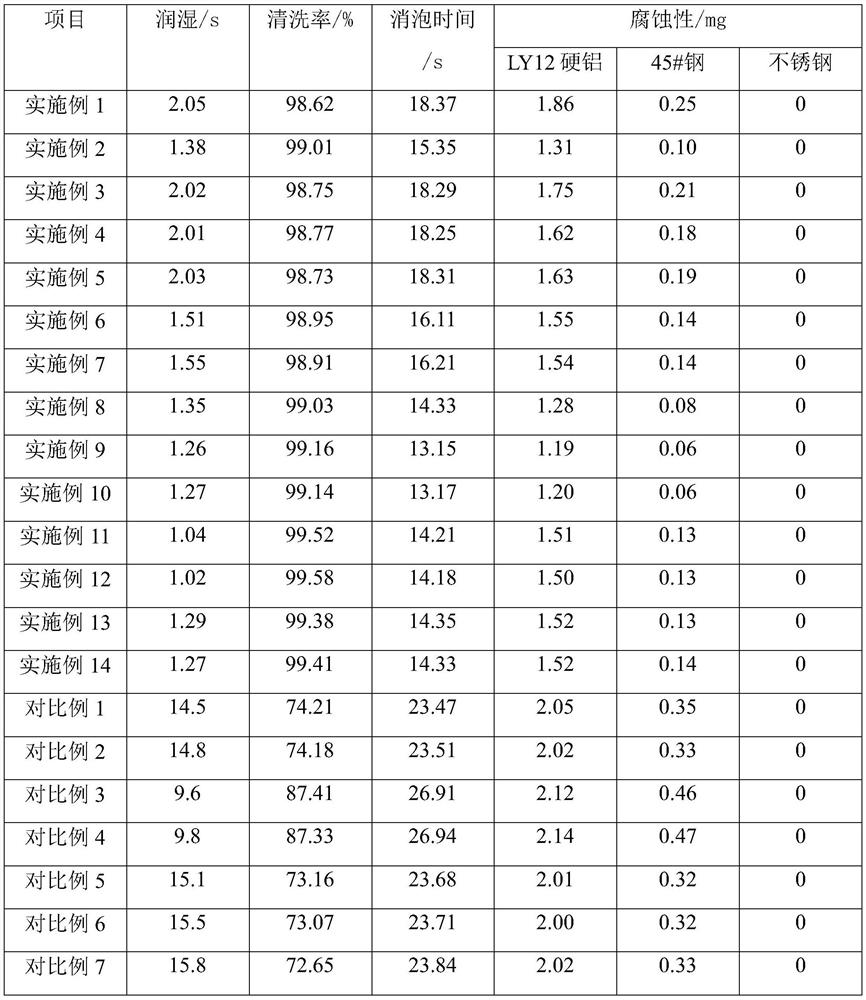

Examples

preparation example 1

[0058] Litten is prepared by using the following methods:

[0059] 50 kg of citrus peel particles, 1.5 kg of sodium chloride and 240 kg of water were mixed, warmed to 90 ° C, distillation to extract for 145 min, and dispense to obtain a citarne extract.

preparation example 2

[0061] Litten is prepared by using the following methods:

[0062] 52 kg of citrus skin particles, 1.56 kg of sodium chloride were mixed with 245 kg of water, warmed to 92 ° C, evaporated for 150 min, dissection to give a lentate extract.

preparation example 3

[0064] Litten is prepared by using the following methods:

[0065] 54 kg of citrus skin particles, 1.62 kg of sodium chloride and 250 kg of water were mixed, warmed to 94 ° C, distilled 155 min, dispense, to obtain a lenta extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com