A kind of preparation method and application of amino acid chelated zinc modified lamina tencel fiber

A technology of amino acid and chelated zinc, which is applied in artificial filaments made of cellulose derivatives, skin care preparations, pharmaceutical formulations, etc., can solve the problems of less research on anti-oxidation, and achieve improved anti-oxidation, scavenging Good effect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

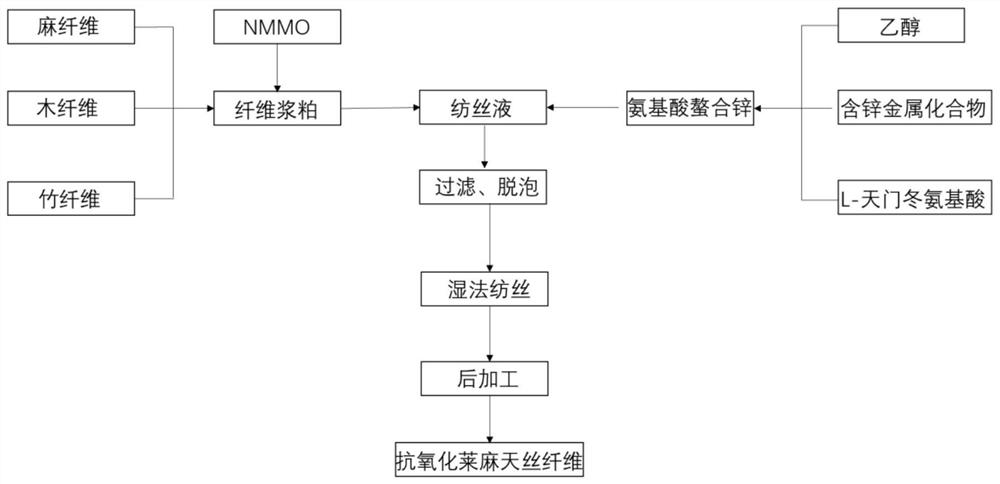

[0021] like figure 1 As shown, in the present invention, the preparation method of L-aspartic amino acid chelated zinc modified lamina tencel fiber comprises the following steps:

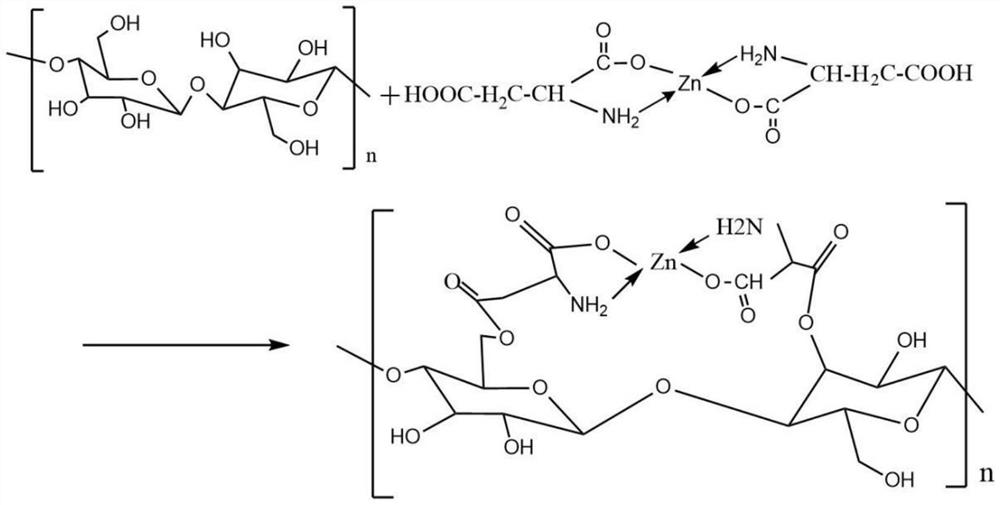

[0022] (1) Add 0.538g L-aspartate amino acid and 20mL distilled water to the round-bottomed flask, heat the oil bath to 40-55°C with magnetic stirring, slowly add the corresponding proportion of zinc nitrate aqueous solution, record the reaction start time, use 6mol / L NaOH solution to adjust the pH of the reaction solution to 4-7, the temperature was raised to 50-65 ℃ and the reaction was incubated for 1 h. After the reaction was completed, anhydrous ethanol was added to precipitate the chelate, centrifuged, and dried to obtain L-aspartic amino acid. Chelated zinc.

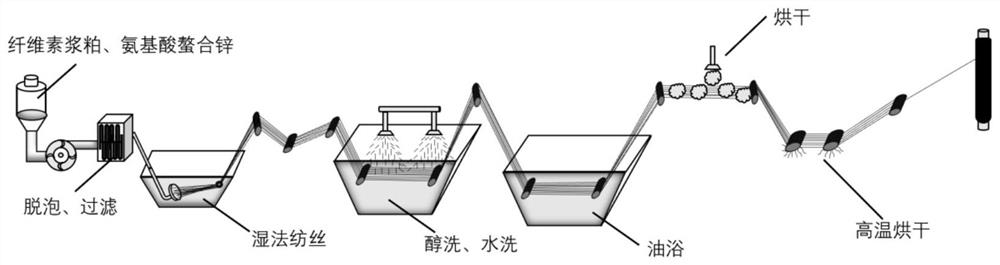

[0023] (2) The NMMO aqueous solution with a mass fraction of 45%-55% was distilled under reduced pressure to a suitable concentration of NMMO aqueous solution, and the amino acid chelated zinc and cellulose pulp were dissolved in the ...

Embodiment 1

[0031] The preparation of L-aspartic amino acid chelated zinc modified Laem Tencel fiber, the steps are as follows:

[0032] (1) Add 0.538g L-aspartate amino acid and 20mL distilled water to the round-bottomed flask, heat the oil bath to 40°C with magnetic stirring, slowly add the corresponding proportion of zinc nitrate aqueous solution, record the reaction start time, use 6mol / L The pH of the reaction solution was adjusted to 6 with the NaOH solution, the temperature was raised to 60°C and the reaction was incubated for 1 h. After the reaction was completed, anhydrous ethanol was added to precipitate the chelate, centrifuged, and dried to obtain L-aspartic amino acid chelated zinc.

[0033] (2) The NMMO aqueous solution with a mass fraction of 45%-55% was distilled under reduced pressure to a suitable concentration of NMMO aqueous solution, and 10 g of the amino acid chelated zinc obtained in step (1) and 500 g of cellulose pulp were dissolved in the NMMO aqueous solution, ce...

Embodiment 2

[0036] The L-aspartic amino acid chelated zinc modified L-hemp tencel fiber is prepared according to the method of Example 1, the difference is: in step (1), the zinc-containing metal compound Zn(OH) is selected 2 Mix the ingredients with L-aspartic amino acid in a molar ratio of 2:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com