A kind of online preparation device and using method of antibacterial non-woven fabric for medical mask

A technology of nonwoven fabrics and preparation devices, which is applied in the field of preparation of nonwoven fabrics for medical masks and on-line preparation devices for antibacterial nonwoven fabrics for medical masks. Solve problems such as modification process limitations, and achieve the effect of strong ability, good washing resistance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

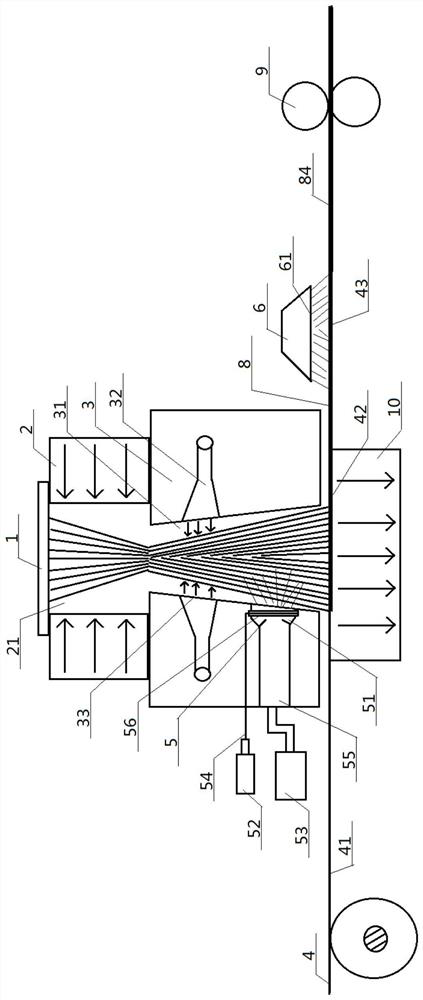

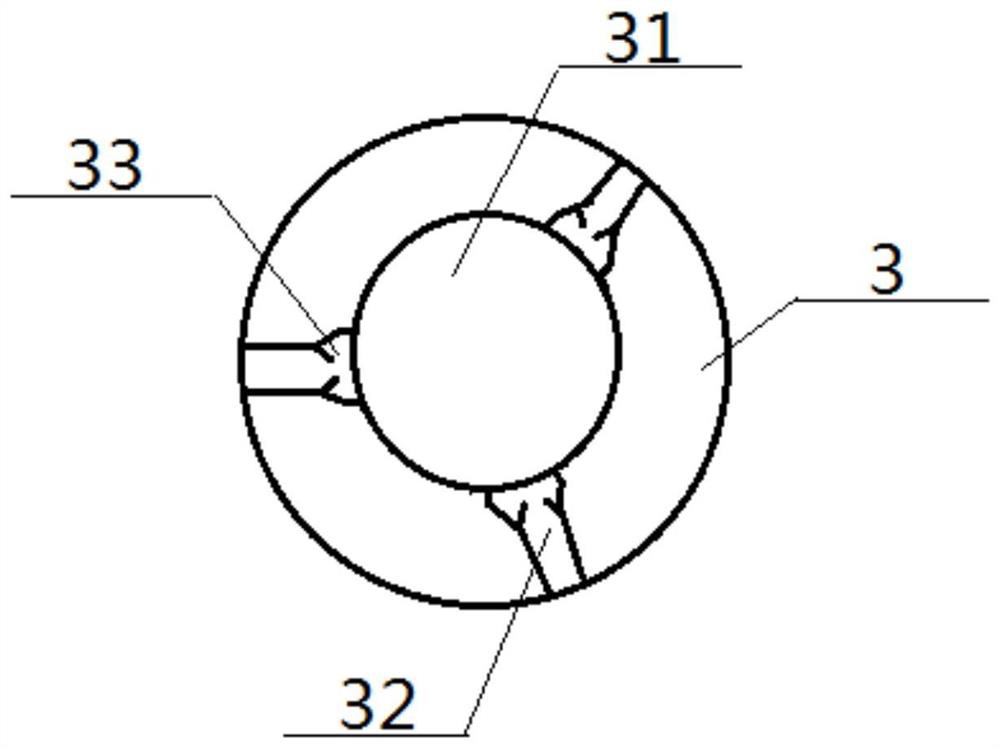

[0055] see figure 1 — Figure 5 , an on-line preparation device for antibacterial nonwoven fabrics for medical masks, comprising a spinneret 1, a cooler 2, a drafter 3 and a conveying net curtain 4, the interior of the cooler 2 is provided with a cooling chamber 21, and the drafting The inside of the device 3 is provided with a drafting chamber 31, and the bottom of the spinneret 1 communicates with the top of the conveying mesh curtain 4 after passing through the cooling chamber 21 and the drafting chamber 31 in turn; the conveying mesh curtain 4 includes upstream Section 41, laying section 42 and downstream section 43, said laying section 42 is arranged opposite to the bottom of drafting chamber 31, said downstream section 43 is provided with negative liquid sprayer 6, and the bottom of said negative liquid sprayer 6 is arranged The negative liquid spray port 61 and the top of the downstream section 43 are arranged oppositely; the drafting jet 32 and the mixing sprayer 5 ...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

[0059] The cationic polyelectrolyte is any one or any mixture of sodium alginate, hyaluronic acid, polyacrylic acid, polystyrenesulfonic acid, polyethylenesulfonic acid, polyvinylphosphoric acid;

[0060] The anionic polyelectrolyte is any one of polypropylene hydrochloride, chitosan, polydivinyl propyl dimethyl ammonium chloride, polyethyleneimine, polyquaternary ammonium salt, polyvinylpyridine or any mixed .

Embodiment 3

[0062] Basic content is the same as embodiment 1, the difference is:

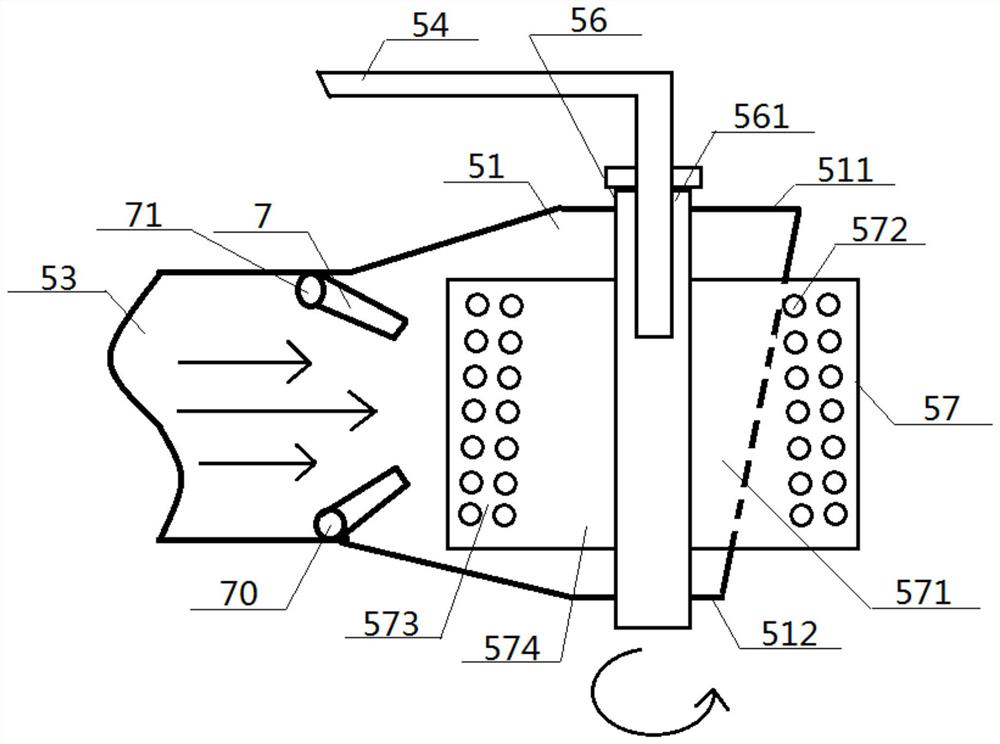

[0063] Described mixing sprayer 5 comprises powder tube 54, tube 55 for transporting yang liquid and mixing spray port 51, and one end of the tube 55 for transmitting yang is connected with liquid device 53 for transmitting yang, and the other end of liquid tube 55 for transmitting yang is mixed The spray port 51 communicates with the drawing chamber 31; the mixing spray port 51 is provided with a rotating tube 56 and at least two rotating pieces 57, and the top and bottom ends of the rotating tube 56 are respectively connected to the top spray of the mixing spray port 51. The wall 511 and the bottom mist wall 512 carry out corresponding rotation cooperation, the side circumference of the rotating tube 56 is connected with the inner end of the rotating piece 57, and the outer end of the rotating piece 57 extends outward; the inside of the rotating tube 56 is provided with a tube lumen 561, the inside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com